• Standard tubing pump with stable flow rate

• Roller sets with high discharge pressure and high flow rate stability

▮ The roller set is integrated and can be easily attached and detached.

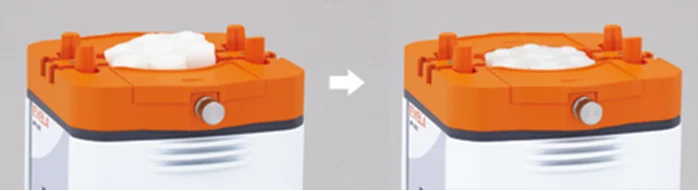

▮ A locking mechanism has been added to the stoppers on both ends of the tubing case. It can be locked when set, making it easy to move and replace tubing.

▮ A wide range of characteristics can be obtained by adding or changing tubing cases.

▮ The rotation direction can be easily switched between forward and reverse with just turning the switch.

▮ High precision discharge with excellent flow rate reproducibility. Suitable for precise liquid dispensing.

▮ For tubing with an outer diameter ranging from 3 to 6.1mm, MP-2000 and MP-2010 support 2 channels, while MP-2100 and MP-2110 support 4 channels, allowing simultaneous liquid dispensing to 2 or 4 locations.

• Simple control panel

♦ High discharge accuracy and excellent flow rate reproducibility. Suitable for precise micro-volume dispensing.

♦ The rotation direction (forward/reverse) can be easily switched with a single button.

• Specifications

| Model | MP-2000 | MP-2010 | MP-2100 | MP-2110 |

| Cat. No. | 251288 (220V), 251289 (115V) |

251308 (220V), 251309 (115V) |

252628 (220V), 252629 (115V) |

252648 (220V), 252649 (115V) |

| Type | Standard | Low flow rate | Standard | Low flow rate |

| Tubing holder method | Adjustable screw type | |||

| Flow rate range | 10 to1450mL/h x 2 | 0.5 to 72.5mL/h x 2 | 10 to 1450mL/h x 4 | 0.5 to 72.5mL/h x 4 |

| Flow rate accuracy | Within ± 2% (repeatability within ± 1%) | |||

| Max. discharge pressure | 196kPa (2kg/cm2) | |||

| Max. suction pressure | 9.8kPa (0.1kg/cm2) | |||

| Fluid viscosity・temperature | Max. 2Pa·s (2000cP)・0 to 60℃ (no freezing) | |||

| Rotation setting | Rotation speed control knob | |||

| Pumping direction | Forward・reverse switchable | |||

| Motor | AC speed control induction motor, output 15W | |||

| Tubing case material | PET resin | |||

| Safety features | Thermal protector, Fuse | |||

| Number of tubes | 2 pcs | 4 pcs | ||

| Number of tubing cases | Single stage (can be expanded up to double stages) | Double stages | ||

| Usable tubing material | Silicone, Tygon®, Versilon (Fluran®), PharMed® | |||

| Usable tubing diameter | 3 to 6.1mm OD | |||

| Ambient temperature range | 0 to 40℃ (no condensation) | |||

| Outer dimensions (mm) | 137(166)W x 145(164)D x 177(190)H | 137(166)W x 145(164)D x 206(219)H | ||

| Weight | Approx. 3.1kg | Approx. 3.2kg | Approx. 3.4kg | Approx. 3.5kg |

| Power input・supply voltage | 0.2A, 40VA・ 220VAC 50/60Hz, 0.4A, 40VA・115VAC 60Hz | |||

| Model | MP-2000A | MP-2010A | MP-2000B | MP-2010B |

| Cat. No. | 251328 (220V), 251329 (115V) |

251338 (220V), 251339 (115V) |

251348 (220V), 251349 (115V) |

251358 (220V), 251359 (115V) |

| Type | Standard | Low flow rate | Standard | Low flow rate |

| Tubing holder method | Fixed-width groove type | |||

| Flow rate range | 10 to 180mL/h | 0.5 to 9mL/h | 80 to 1450mL/h | 5 to 72.5mL/h |

| Flow rate accuracy | Within ± 2% (repeatability within ± 1%) | |||

| Max. discharge pressure | 147kPa (1.5kg/cm2) | |||

| Max. suction pressure | 9.8kPa (0.1kg/cm2) | |||

| Fluid viscosity・temperature | Max. 2Pa·s (2000cP)・0 to 60℃ (no freezing) | |||

| Rotation setting | Rotation speed control knob | |||

| Pumping direction | Forward・reverse switchable | |||

| Motor | AC speed control induction motor, output 15W | |||

| Tubing case material | PVC resin | |||

| Safety features | Thermal protector, Fuse | |||

| Number of tubes | 1 pc | |||

| Number of tubing cases | Single stage | |||

| Usable tubing material | Silicone, Tygon®, Versilon (Fluran®), PharMed® | |||

| Usable tubing diameter | 1.15 ID x 3.2mm OD |

3.7 ID x 6.1mm OD |

||

| Ambient temperature range | 0 to 40℃ (no condensation) | |||

| Outer dimensions (mm) | 137W x 145(164)D x 178(191)H | |||

| Weight | Approx. 3.3kg | |||

| Power input・supply voltage | 0.2A, 40VA・ 220VAC 50/60Hz, 0.4A, 40VA・115VAC 60Hz | |||

| Model | MP-2001 | MP-2011 | MP-2101 | MP-2111 |

| Cat. No. | 251298 (220V), 251299 (115V) | 251318 (220V), 251319 (115V) | 252638 (220V), 252639 (115V) | 252658 (220V), 252659 (115V) |

| Type | Standard | Low flow rate | Standard | Low flow rate |

| Tubing holder method | Spring type | |||

| Flow rate range | 10 to 1450mL/h x 2 | 0.5 to 72.5mL/h x 2 | 10 to 1450mL/h x 4 |

0.5 to 72.5mL/h x 4 |

| Flow rate accuracy | Within ± 2% (repeatability within ± 1%) | |||

| Max. discharge pressure | 98kPa (1kg/cm2) | |||

| Number of tubes | 2 pcs |

4 pcs | ||

| Number of tubing cases | Single stage (can be expanded up to double stages) |

Double stages |

||

| Usable tubing material | Silicone, Tygon®, Versilon (Fluran®), PharMed® | |||

| Usable tubing diameter | 3.2 to 6.1mm OD | |||

| Ambient temperature range | 0 to 40℃ (no condensation) | |||

| Outer dimensions (mm) | 137(166)W x 145(164)D x 177(190)H | 137(166)W x 145(164)D x 206(219)H | ||

| Weight | Approx. 3.1kg | Approx. 3.2kg | Approx. 3.4kg | Approx. 3.5kg |

| Power input・supply voltage | 0.2A, 40VA・220VAC 50/60Hz, 0.4A 40VA・115VAC 60Hz | |||

◊ Tubing is sold separately. Flow rate, discharge pressure, and other performance may vary slightly depending on the tubing used.

◊ When the viscosity of the liquid exceeds 0.1Pa·s (100cP), the discharge volume may decrease.

◊ Not suitable for use with a step-down transformer.

◊ The liquid temperature specifications are based on the pump bodyʼs heat resistance. The lifespan of the tubing will vary depending on the type of liquid and temperature used.

◊ The dimensions in parentheses ( ) include protrusions.

• Introduction video of EYELA peristaltic pumps

• Three types of tubing holders are available

▮ Adjustable screw type (MP-2000・2010・2100・2110)

The tubing holder is adjusted using a conventional screw. It can be adjusted to a constant discharge pressure regardless of the type or thickness of the tubing.

▮ Spring type (MP-2001・2011・2101・2111)

The tubing holder is pressed with an internal spring mechanism. No adjustment is needed for

tightening, as the tubing is consistently pressed with a fixed force. This reduces flow rate errors

during tubing replacement and minimizes tubing deterioration due to over-tightening.

* The maximum discharge pressure varies depending on the type of tubing.

▮ Fixed-width groove type (MP-A・B series)

The machining tolerance of the tubing case is specified, so by combining it with our genuine tubing, which have specified tolerances for the tubing thickness, there is almost no variation in flow rate or fluctuation in discharge pressure when replacing the tubing.

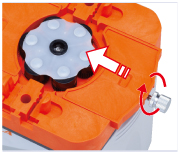

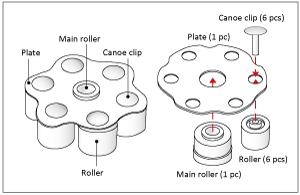

• One-touch installation of the integrated roller set

The integrated roller set can be smoothly installed by simply turning the switch ON.

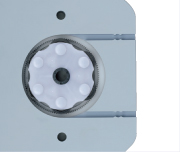

• Composition of the roller section

| Integrated roller set | Cat. No. 252570 |

| Main roller | Cat. No. 252550 |

| Roller (6 pcs) | Cat. No.252560 |

| Clip (6 pcs)・plate (1 pc) set | Cat. No.196150 |

• Options

• Adapter set tubing

| Tubing type | Silicone, PharMed®, Tygon®, Versilon (Fluran®) | By using the adapter set tube, only the worn sections of the tube can be replaced during operation. The tube and tubing case can be connected with a one-touch fitting. |

| Compatible size (ID x OD) | 1.15 x 3.2mm, 2.15 x 4.2mm, 3.15 x 5.2mm, 3.7 x 6.1mm |

◊ The adapter set tubing comes as a single set (one channel).

◊ It cannot be used with MP-2000A・B or MP-2010A・B.

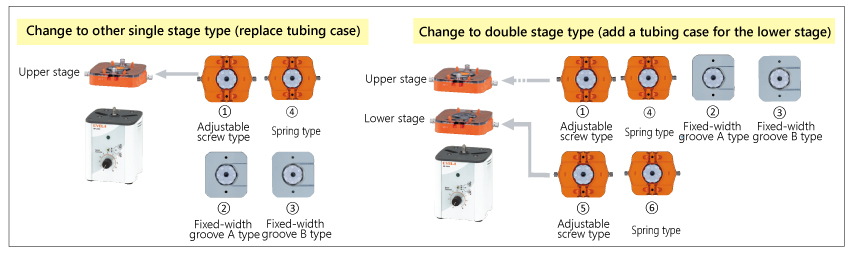

• Tubing case compatibility (MP-2000 and 2100 series)

◊ Please ensure that the tubing case types are the same for the upper and lower stages in case of adjustable screw model.

The tubing case fixing bolts for the double stage and the joint shaft for the lower tubing case are included with the lower stage tubing case.

| Tubing case set | Model | Cat. No. | |

| ① | Change to MP-2000・2010 For MP-2000・3000・4000 series |

TCS-0 | 251220 |

| ② | Change to MP-2000A・2010A For MP-2000A・3000A series |

TCS-A | 251240 |

| ③ | Change to MP-2000B・2010B For MP-2000B・3000B series |

TCS-B | 251250 |

| Tubing case set | Model | Cat. No. | |

| ④ | Change to MP-2001・2011 For MP-2000・3000・4000 series |

TCS-1 | 251260 |

| ⑤ | Change to MP-2100・2110 For MP-2000・3000 series lower stage |

TCS-100 | 251230 |

| ⑥ | Change to MP-2101・2111 For MP-2000・3000 series lower stage |

TCS-101 | 251270 |

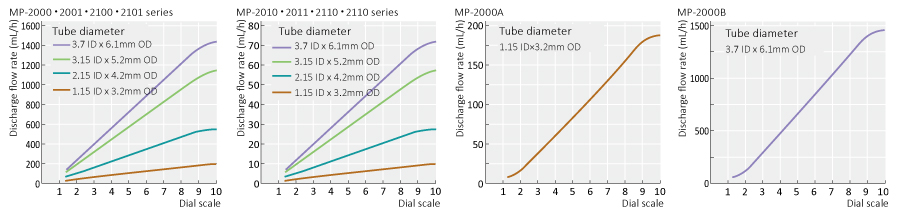

• Data

• Flow rate characteristics

Conditions: Silicone tubing, deionized water, liquid temperature: approx. 18℃, room temperature: 20℃, back pressure: 0