• A wide variety of rotary evaporators available

Since the release of the N-1 model evaporator in 1965, EYELA’s rotary evaporator series has been beloved for over 50 years and highly regarded in laboratories in Japan. To support the development of better research environments, we offer a wide range of models.

| Compact condenser suitable for installation in a fume hood |

Condenser suitable for small to large volume flasks | Condenser suitable for low to high boiling point substances |

| Evaporator (driving unit) + Type E condenser (vertical double spiral, adapter integrated) + Water bath | Evaporator (driving unit) + Type V condenser (vertical double spiral) + Water bath | Evaporator (driving unit) + Type S condenser (diagonal double spiral) + Water bath |

| N-1300E series | N-1300V series | N-1300S series |

• A rotary evaporator that fits anywhere you need it!

| The condenser can be installed on either the left or right side depending on the installation location | Easy to install and use stand base and bath |

|

|

| The condenser can be installed to either the left or right side of the main unit. This allows you to position the equipment considering the available bench space and your dominant hand. | The shape of the stand base and water・oil bath has been improved to a circular shape, so the bath can be faced forward regardless of the installation angle (position) of the evaporator. The bath temperature can be observed and set at any time. |

▶▶ Example of sea water concentration

• Concentration operation using vacuum controller

♦ NVC-3000 vacuum controller

◊ The controller can display not only the pressure during operation but also the cooling water temperature, bath temperature, rotary evaporator rotation speed, and vapor temperature (sensor sold separately) all in one place.

◊ The entire system automatically starts/stops when the rotary evaporator or vacuum controller starts/stops. Bath is linked only when operation is stopped.

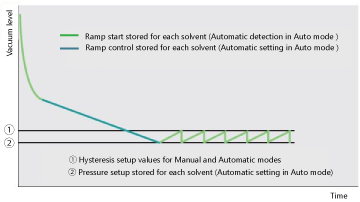

◊ Graph below shows vacuum control function (during ramp program control)

It has the Normal Mode that allows you to change settings as desired during operation, The Auto Mode that automatically detects boiling point, controls ramp, and sets pressure simply by pressing the RUN key, and the Program Mode that controls the appropriate vacuum level by just selecting a solvent name. The appropriate vacuum conditions can always be obtained, resulting in a high solvent recovery rate.

▶▶ Vacuum control mode and features in conjunction with the NVC-3000 vacuum controller

▶▶ Comparison of rotary evaporator systems with and without the NVC-3000 vacuum controller

• Shatterproof coating for glass vessels – EYELA COAT®

The coating agent is an environmentally friendly polyurethane that is resistant to breakage and features a new formulation that minimizes the scattering of glass and samples in the event of breakage. This formulation excels in chemical properties and offers remarkable transparency, making the coating virtually invisible.

• Designed for improved operability

| Liquid accumulation prevention structure | Backflow prevention structure |

|

|

| To minimize the accumulation of liquid that often occurs when using the condenser at an angle, a liquid accumulation prevention structure has been implemented on the receiving flask side. | The condenser attachment position is offset from the capillary, so there is no risk of condensate from the condenser flowback through the capillary tube into the sample flask. |

| Equipped with an automatic reversal function, ideal for drying and concentrating powders and solids | Since it is stepless, it can be fixed (locked) at any position when jacking up |

|

|

| The rotation direction of the flask (forward or reverse) can be set. Automatic rotation can also be set, making it suitable for drying powders and for drying and concentrating samples that contain solids. | The jack can be adjusted steplessly, so it can be easily fixed and released at any position to suit the sample vessel. It is easy to operate even when using a trap ball. |

• Rotary evaporator combination guide

You can freely select the configuration you want according to your needs.

|

The rotary evaporator consists of the following parts. You can freely select your desired configuration. ♦ Evaporator (driving unit) |

• Choose from 3 types of condensers

| Type E condenser Vertical double spiral (N-1300E) |

Type V condenser Vertical double spiral (N-1300V) |

Type S condenser Diagonal double spiral (N-1300S) |

|

|

|

| Type E is equipped with a compact condenser with an integrated adapter. Designed for use inside fume hoods, it features a unique design that prevents condensed liquid inside the condenser from easily flowing back into the sample flask through the capillary. | Type V is equipped with a vertical double spiral condenser. This unique design prevents condensate in the condenser from flowing back through the capillary to the sample flask. This is effective for concentrating analytical samples and other samples that must be free of contamination. | Type S is equipped with a diagonal double spiral condenser that maintains the same size while expanding the cooling surface area and improving efficiency. |

• Select a type of bath

| Bath type | Without bath | Water bath (SB1300) | Water bath with enhanced safety features (SB-1350) | Water・oil bath (OSB-2200) |

| Bath temperature control range • accuracy | N/A | RT + 5 to 90°C • ± 1°C | RT + 5 to 90°C • ± 1°C | RT + 5 to 180°C • ± 1.5°C (Oil: ± 3°C) |

| Configuration |  |

|

|

|

| N-1300∇ | N-1300∇-W | N-1300∇-WS | N-1300∇-WB |

◊ The condenser type (E • V • S) goes into “∇”.

▶▶ Introducing the assembly and precautions for the N-1300 series

• Specifications of three types of condensers

| Product name | Rotary evaporator (with manual jack) | ||

| Condenser type | Type E condenser (Compact vertical double spiral with an integrated adapter) |

Type V condenser (Vertical double spiral) |

Type S condenser (Diagonal double spiral) |

| Model | N-1300E△-∅ | N-1300V△-∅ | N-1300S-∅ |

| If it is the shatterproof coating model, “F” is placed in the △. The ∅ contains the bath type | |||

| Specification |  |

|

|

|

Compact condenser suitable for installation in a fume hood (Cooling area 0.117m2 ), Rotary joint (18 ID x total length 178mm TS29/38), 1L sample flask (pear shaped) TS29/38, 1L receiving flask (round shaped) (ball joint S35/20) |

Condenser for small to large volume flasks (Cooling area 0.146m2), Adapter, Rotary joint (18 ID × total length 178mm TS29/38), 1L sample flask (pear shaped) TS29/38, 1L receiving flask (round shaped) (ball joint S35/20) |

Highly efficient condenser for low to high boiling point substances (Cooling area 0.146 m2) Rotary joint (18 ID x total length 272mm TS29/38), 1L sample flask (pear shaped) TS29/38, 1L receiving flask 1L (round shaped) (ball joint S35/20) |

|

• Specifications of evaporator (driving unit) and bath

◊ Performance values are based on room temperature of 20°C and rated power supply voltage.

◊ Evaporation capacity varies depending on conditions such as rotation speed, reduced pressure, bath temperature, condenser temperature, and sample flask.

| Product name | Rotary evaporator (with manual jack) | |||

| Bath type | Without bath | Water bath | Water bath with enhanced safety features | Water・oil bath |

| Model | N-1300∇△ | N-1300∇△-W | N-1300∇△-WS | N-1300∇△-WB |

| The condenser model is indicated by ∇, and “F” in △ denotes a shatterproof coating model | ||||

| Bath temperature control range • accuracy (when stirring in flask) | N/A | RT + 5 to 90°C • ± 1°C | RT + 5 to 90°C • ± 1°C | RT + 5 to 180°C • ± 1.5°C (Oil: ± 3°C) |

| Bath safety functions | N/A | Fuse, Fixed temperature overheat protector, Insulated protective bath cover | Dry-heating protection unit (float switch), Fixed temperature overheat protector, Dedicated bath detector, Fuse, Insulated protective bath cover, Self-diagnostic function | Fuse, Fixed temperature overheat protector, Insulated protective bath cover |

| Bath materials | N/A | Stainless steel | Stainless steel | Aluminum (Teflon® coating) |

| Bath inner dimensions (mm) | N/A | 220 ID x 120H | 220 ID x 120H | 240 ID x 120H |

| Bath capacity | N/A | Approx. 4.3L | Approx. 4.3L | Approx. 5.4L |

| Bath heating | N/A | Heater: 1.05kW | Heater: 900kW | Heater: 1kW |

| Rotation speed range | 10 to 310rpm | |||

| Evaporation capacity | Max. 23mL/min (JIS standard 1L flask, water evaporation rate) | |||

| Rotation setting・display | Dial setting input • digital display | |||

| Jack functions | Manual balance type (jack stroke 180mm, stepless adjustment) | |||

| External input • output | Vacuum controller NVC-3000 communication terminal, low temperature circulator communication terminal | |||

| Motor | Brushless DC motor | |||

| Vacuum seal | Vacuum seal (Teflon® + Teflon® • Viton double seal) 1 set | |||

| Connection port diameter | Cooling water nozzle • Suction nozzle 10mm OD | |||

| Ambient temperature range | 5 to 35°C | |||

| Power input • supply voltage | 1.1A, 110VA・100 to 240VAC 50/60Hz | 5.3A, 1.16kVA・230VAC 50/60Hz or 10.6A, 1.16kVA・115VAC 50/60Hz | 11.6A, 1.16kVA・100VAC 50/60Hz | 5A, 1.11kVA・230VAC 50/60Hz or 10A, 1.11kVA・115VAC 50/60Hz |

• List of combinations for condenser, bath and jack

◊ Products with an “F” in the model number feature the EYELA COAT® (shatterproof coating) specification, with a coating applied to the condenser, adapter, and receiving flask. (No coating is applied to the rotary joint or pear shaped sample flask.)

| Condenser type | EYELA-

COAT® |

Bath type | Outer dimensions (mm) | Model | Cat. No. |

|

Type E

|

No shatterproof coating | Without bath | 514W x 342D x 645H (Highest position 825) | N-1300E | – |

| Type V

|

479W x 342D x 785H (Highest position 965) | N-1300V | – | ||

| Type S

|

672W x 342D x 504H (Highest position 684) | N-1300S | – | ||

| Type E | Water bath | 578W x 352D x 645H (Highest position 825) | N-1300E-W | – | |

| Type V | 543W x 352D x 785H (Highest position 965) | N-1300V-W | – | ||

| Type S | 736W x 352D x 504H (Highest position 684) | N-1300S-W | – | ||

| Type E | Water bath with enhanced safety features |

578W x 374D x 645H(Highest position 825) |

N-1300E-WS | – | |

| Type V | 543W x 374D x 785H (Highest position 965) | N-1300V-WS | – | ||

| Type S | 736W x 374D x 504H (Highest position 684) | N-1300S-WS | – | ||

| Type E | Water・oil bath | 565W x 352D x 645H (Highest position 825) | N-1300E-WB | – | |

| Type V | 531W x 352D x 785H(Highest position 965) | N-1300V-WB | – | ||

| Type S | 724W x 352D x 504H (Highest position 684) | N-1300S-WB | – | ||

| Type E |

EYELA- COAT®

|

Without bath | 514W x 342D x 645H (Highest position 825) | N-1300EF | – |

| Type V | 479W x 342D x 785H (Highest position 965) | N-1300VF | – | ||

| Type E | Water bath | 578W x 352D x 645H (Highest position 825) | N-1300EF-W | – | |

| Type V | 543W x 352D x 785H (Highest position 965) | N-1300VF-W | – | ||

| Type E | Water bath with enhanced safety features | 578W x 374D x 645H (Highest position 825) | N-1300EF-WS | – | |

| Type V | 543W x 374D x 785H (Highest position 965) | N-1300VF-WS | – | ||

| Type E | Water・oil bath | 565W x 352D x 645H (Highest position 825) | N-1300EF-WB | – | |

| Type V | 531W x 352D x 785H (Highest position 965) | N-1300VF-WB | – |

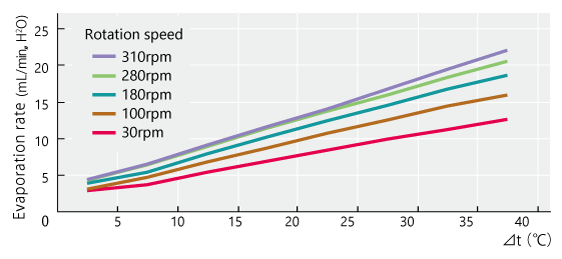

• Data

♦ Evaporation capacity curve

⊿t: The difference between the bath temperature and the boiling point of the sample (water)

Conditions: Cooling water temperature set to 0°C, room temperature 20 to 21°C, JIS sample flask 1L (500mL charge). The evaporation amount is calculated based on the time from when the sample begins to boil until it evaporates completely.

• Anti-condensation covers

The dedicated cover designed to reduce condensation on the condenser and nozzles.

| Product name | Anti-condensation cover | |

| Compatible condenser | Type E • V | Type S |

| Cat. No. | 270740 | 270730 |

| Included | Condenser cover, nozzle cover (2 pcs) | |

| Materials | PP, insulation material, urethane foam | |

| Usage conditions | Circulating fluid temperature: -10°C or above (when using low temperature heat transfer medium) | |

By attaching dedicated covers to the condenser and nozzles of the rotary evaporator, the formation of condensation (water droplets) can be significantly reduced. These covers can be installed not only on new products but also on our previously released models.

▶▶ Showing the effectiveness of anti-condensation cover

• Transparent cover for checking condensation status

| Product name | Anti-condensation transparent cover | |

| Compatible condenser | Type V • S | Type E |

| Cat. No. | 266110 | 270350 |

| Included | Condenser cover, nozzle cover (2 pcs) | |

| Materials | Transparent PET• silicone, Foamed silicone | |

| Usage conditions | Circulating fluid temperature 5°C or above | |

By attaching dedicated covers to the condenser and nozzles of the rotary evaporator, the formation of condensation (water droplets) can be significantly reduced. These covers can be installed not only on new products but also on our previously released models.

• Optional parts

♦ Standard parts

Rotary joints, Sample flasks (pear shaped), Receiving flasks, Ball traps, Separable flasks, Test tubes • Glass reducing adapters, Condensers • Adapters, Vacuum seals • Teflon® seals, Vacuum hoses • Insulated hoses, Capillaries, Bumping prevention devices, etc. are available. Please purchase them as required.

♦ EYELA COAT® (shatterproof coating)

Condensers, Receiving flasks, and Adapters are available as standard EYELA COAT® products. The coating is an environmentally friendly polyurethane that is less likely to break and has a new composition that prevents glass and samples from scattering in the unlikely event of breakage. This composition has excellent chemical properties and is so transparent that the coating is not noticeable.