A flexible unit-based freeze dryer for building tailored freeze-drying systems

♦ Both FDM-1000 and FDM-2010 can process up to 1L of moisture per batch. These unit-based freeze dryers offer flexible system configuration by allowing users to select appropriate manifolds or drying chambers according to the sample vessels.

♦ Model FDM-2010 uses an environmentally friendly natural refrigerant.

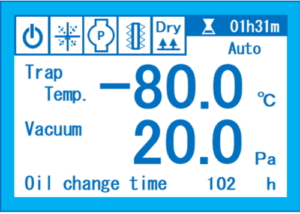

• Bright, easy-to-read 3.4-inch LCD display

♦ It features an LCD screen that provides a clear overview of the equipment status, including the trap temperature, vacuum level, and other important operational conditions at a glance.

• Simple operation

♦ In Auto Mode, the system monitors the cold trap temperature and vacuum level to notify you when the sample vessel is ready to be mounted. Once started, the operation involves only simple steps—mounting the flasks and stopping the process at the end of freeze drying.

• Equipped with timer function

♦ The display of the vacuum pump’s cumulative operating time and freeze-drying duration helps determine the appropriate timing for vacuum pump oil changes and provides a convenient way to measure sublimation time.

• Contamination prevention and nitrogen purge available

♦ The 0.2 μm filter on the air inlet prevents contamination in the event of a vacuum leak.

♦ Nitrogen purging is also available to prevent sample oxidation.

• Power failure recovery countermeasures

♦ During power outage recovery, the vacuum pump does not automatically restart. This prevents the sample from scattering due to bumping caused by the sample having thawed due to the power failure.

• Recorder output terminal

♦ For drying data management, the device is equipped with standard output terminals for recording vacuum levels and trap temperatures. The dedicated recorder connection cord is optional.

• Model FDM-1000 can also be used as a trap

♦ By using the optional cover with nozzle, FDM-1000 can also be used as a trap for centrifugal evaporators (A vacuum pump with a maximum capacity of 533Pa or less is required).

• Specifications

| Product name | Freeze Dryer | |

| Model | FDM-1000 | FDM-2010 |

| Cat. No. | 280898 | 284710 |

| Cooling method | Cooling coil | Cold trap chamber cooling |

| Cold trap temperature | -45℃ | -80℃ |

| Dehumidifying volume | 1L / batch | |

| Setting ・display | Membrane keypad, LCD display | |

| Trap thermometer | Trap thermometer included | |

| Vacuum gauge | Pirani vacuum gauge (digital display) 0.0 to 533Pa | |

| Safety functions | Leakage/earth leakage breaker, Refrigerator overload relay, Automatic release upon vacuum leak, Oil change alarm, Fuse for service outlet, Control board self-diagnostic function | |

| Vacuum release function | Automatic vacuum release valve | |

| Trap defrost | Defrosting by hot gas | |

| Additional functions | Vacuum pump automatic control, Vacuum・trap temperature monitoring function, Stopwatch function, Power failure recovery time selection function, Vacuum degree abnormality monitoring (fixed value), refrigerator protection timer | |

| Recorder output | Temperature 1℃/1mV, vacuum 1Pa/mV | |

| Vacuum pump | Option: 50L/min or more | |

| Number of ports | Depends on option selection | |

| Refrigerator・refrigerant | Air-cooled, output 450W・R507A | Air-cooled, output 450W x 2・R290・R170 |

| Global Warming Potential (GWP value) |

3990 | 23 |

| Temperature sensor | T thermocouple | |

| Chamber material | Depends on option selection | |

| Chamber inner dimensions | Depends on option selection | |

| Trap chamber capacity | 1L | |

| Trap chamber dimensions | 200 ID x 175H mm | 153 ID x 225H mm |

| Cooling coil | Coil inside the trap | No coil exposure |

| Trap materials | Stainless steel | |

| Suction port diameter | 17.3 OD (mm) | |

| Sample vessel mounting port | Depends on option selection | |

| Service outlet | For vacuum pump Max.6A, For dry chamber Max.2A | |

| Ambient temperature range | 5 to 35℃ | |

| Power input | 3A, 500VA | 10A, 1kVA |

| Power supply voltage | 220VAC 50/60Hz | 100VAC 50/60Hz |

| Power supply utility | 15A AC100V | 20A AC100V |

| Outer dimensions (mm) | 450W x 420D x 460H | 450(487)W x 550D x 945H |

| Power cord | Length : 3m, Approx. 9mm OD | |

| Weight | Approx. 38kg | Approx. 83kg |

◊ Performance values are at room temperature of 20°C, rated power supply voltage, 50 Hz.

◊ Power input does not include the capacity of the service outlet.

◊ Dimensions in parentheses ( ) include protrusions.

◊ The amount of cooling gas charged is indicated on the serial number plate on the main unit.

◊ When connecting to a recorder, a dedicated recorder connection cord (optional) is required.

About Model FDM-2010

◊ Please prepare a primary power supply of AC100V, 20A capacity.

◊ Power plug is not included.

◊ We also offer corrosion-resistant coatings for the cold trap. Please contact your local distributor for more information.

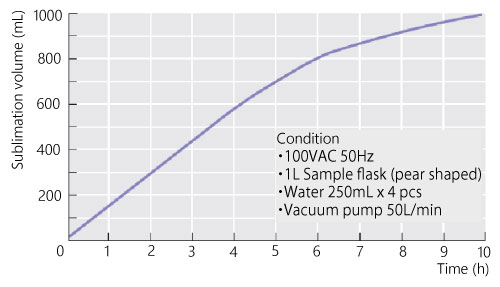

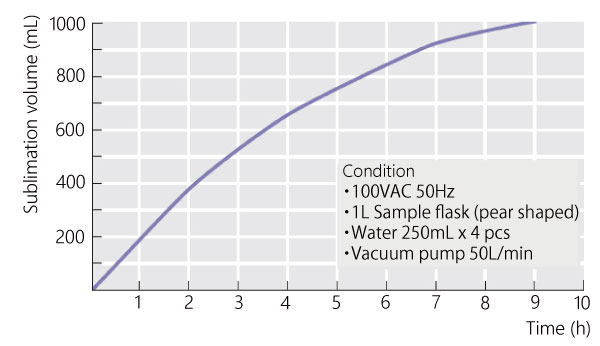

• Data on Sublimation rate

♦ FDM-1000

♦ FDM-2010

The sample (water) is placed in a sample flask (pear shaped) and attached to the trap after pre-freezing, and then estimating the sublimation amount based on the remaining content in the flask after a certain period of time.

• Options

The following options are required for using the equipment. Please carefully select them based on the type and quantity of vessels, loading volume, and characteristics of the sample. Additionally, please ensure that you select the correct options for each specific model, FDM-1000 and FDM-2010, as indicated.

| Product name | Taper joint | Number of port | Model | Cat. No. |

| Manifolds for flasks

◊ When using vessels other than TS29/38, a separate adapter is required. |

||||

|

TS29/38 | 4 | PMH-4A | 209560 |

|

TS29/38 | 4 | PMH-4 | 119820 |

|

TS29/38 | 8 | PMH-8 | 119830 |

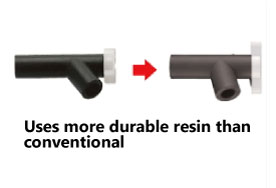

| Manifolds for flasks (high durability, autoclavable type)

◊ A separate adapter is required when using containers other than TS29/38. |

||||

|

TS29/38 | 4 | PMH-4AB | 276060 |

| TS29/38 | 4 | PMH-4B | 276050 | |

| TS29/38 | 8 | PMH-8B | 276070 | |

| Manifold for test tubes and ampoules

◊ Test tube and ampoule adapters are required separately. |

||||

|

TS29/38 | 12 | PMH-12 | 119840 |

|

TS29/38 | 24 | PMH-24 | 119860 |

| Manifolds for test tubes and ampoules (high durability, autoclavable type)

◊ Test tube and ampoule adapters are required separately. |

||||

|

TS29/38 | 12 | PMH-12B | 276080 |

|

TS29/38 | 24 | PMH-24B | 276090 |

| Fixing bracket (fix the manifold with the manifold fixing clamp) | 209580 | |||

| Fixing bracket (Fix the manifold with the acrylic base support) | 213810 | |||

| Product name | Shelf dimensions (mm) | Number of shelves | Max. number of 10mL vials | Max. number of 66mm diameter petri dish | Temperature control range | Model | Cat No. |

| Drying chambers |

|||||||

|

200W x 230D | 2 | 72 pcs x 2 | 8 pcs x 2 | RT+5 to 40℃ | DRC-1N | 119730 |

|

220 diameter | 1 | 58 pcs x 1 | 7 pcs x 1 | 30℃ fixed | DRC-2L | 119750 |

|

220 diameter | 3 | 58 pcs x 3 | 7 pcs x 3 | DRC-3L | 119770 | |

| Sealing drying chambers | |||||||

|

220 diameter | 1 | 58 pcs x 1 | − | 30℃ fixed | BSC-2L | 119790 |

|

220 diameter | 2 | 58 pcs x 2 | − | BSC-3L | 119810 | |

♦ Stainless steel vats and holders for vials

Convenient vats and folders for use in dry chambers.

Please check here for more information.

♦ Pre-freezing products

| Product name | Pre-freezing bath

|

Pre-freezer

(Used in combination with pre-freezing bath) |

| Model | PFR-1000 | PFM-1000 |

| Cat. No. | 197410 | 197420 |

| Pre-freezing temperature | -45℃ | - |

| Compatible vessels | Sample flask

Max.2L |

Sample flask

(TS29/38) |

| Freeze drying bottle

Max.1.2L |

Freeze drying bottle | |

| Applicable models | - | PFR-1000, UT-3010・4000 |

| Rotation speed range | - | 92 /110rpm fixed |

♦ Vacuum pumps and others

| Product name | Displacement | Features | Model | Cat. No. |

| Vacuum pumps | ||||

|

50L/min / 60L/min

(50/ 60Hz) |

Standard | GLD-051 | 190840 (100V)・190848 (220V) |

| Corrosion-resistant finish | GCD-051X | 190850 (100V)・190858 (220V) | ||

| Equipped with oil filter and corrosion-resistant finish | GCD-051XF | 191080 | ||

|

135L/min / 162L/min

(50/ 60Hz) |

Standard | GLD-137CN | 270580 (100V)・270588 (220V) |

| Corrosion-resistant finish | GCD-136XN | 189170 (200V) | ||

| Equipped with oil filter and corrosion-resistant finish | GCD-136XNF | 191090 | ||

Oil mist trap (for GCD-051XF & GCD-136XNF) |

OMC-050 | 118680 | ||

| OMC-200 | 118690 | |||

Vacuum hose (15 ID x 36mm OD, 5m) |

- | 217910 | ||

Base for FDM-2010 (connect main unit and pump for easy transport) Base for FDM-2010 (connect main unit and pump for easy transport) |

FDU-BASE | 209540 | ||

Recorder connection cords |

- | 240170 | ||

Recorders |

For FDM-1000 | μR-10000 | 219290 | |

| For FDM-2010 | μR-10000 | 219300 | ||

Cover with nozzle (It allows the equipment to be used as a trap unit) |

FDU-TRAP | 209520 | ||