• Ideal for clean environments and enhanced safety — no alcohol or dry ice required

The PSL-2500 series provides a dry, safe, and efficient alternative to conventional alcohol baths. With a wide range of interchangeable aluminum blocks, it supports a variety of experimental needs, including low-temperature reactions, crystallization, and sample processing.

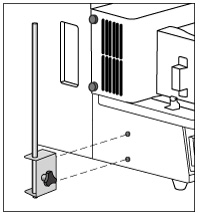

◊ From left to right: PSL-2500A, 2500B, 2500P models shown with optional aluminum block sets and reaction vessels.

◊ From left to right: PSL-2500A, 2500B, 2500P models shown with optional aluminum block sets and reaction vessels.

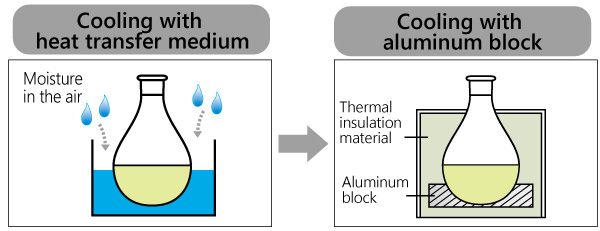

♦ The cooling method uses an aluminum block, eliminating the risk of alcohol ignition and compositional changes caused by moisture absorption. Since no alcohol or dry ice is used, it ensures a clean and highly safe environment.

|

|

| Alcohol baths absorb moisture during cooling, altering their composition and reducing cooling efficiency. Also, if it is left at room temperature, there is a risk of both evaporation and ignition. | In contrast, the aluminum block provides dry, stable cooling with no moisture absorption or composition changes. The temperature is always kept constant. |

• By combining optional aluminum block sets designed for different vessels, various experiments can be conducted to accommodate your specific applications

| PSL-2500A + Aluminum bath set | PSL-2500A + Aluminum bath set x Aluminum beads + PP balls |

|

|

♦ A wide range of vessels — including flasks, test tubes, and centrifuge tubes — can be used by simply changing the aluminum block set to suit your experiment. Furthermore, by attaching an aluminum bath set to the A and B models, aluminum beads can be placed in the bath, allowing the use of vessels of other shapes and sizes. Adding PP balls helps reduce condensation and freezing during continuous operation.

♦ A powerful magnetic stirrer is included as a standard feature.

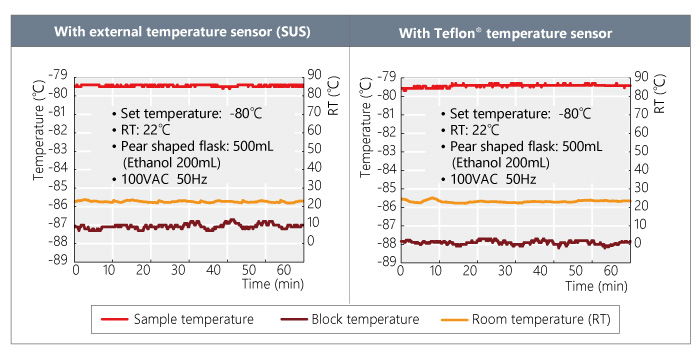

♦ The PSL-2500P model utilizes cascade control to precisely regulate the sample temperature using an external temperature sensor. It also supports ramp programming, making it ideal for precise temperature control during crystallization and recrystallization processes.

Additionally, precise temperature control can be achieved using the standard external temperature sensor or the optional Teflon® sensor.

• Temperature control accuracy (during sample temperature control)

▶▶▶ Introductory video for the PSL-2500 series.

▶▶▶ PSL-2500 reaches the minimum temperature in only 40 minutes, much faster cooling capacity than alcohol baths

The compact PSL-2500A measures 220W × 435Dmm, while the PSL-2500B and P models measure 220W x 630Dmm, making them well-suited for tabletop use. They can be conveniently installed inside a fume hood or on a lab bench without occupying much space.

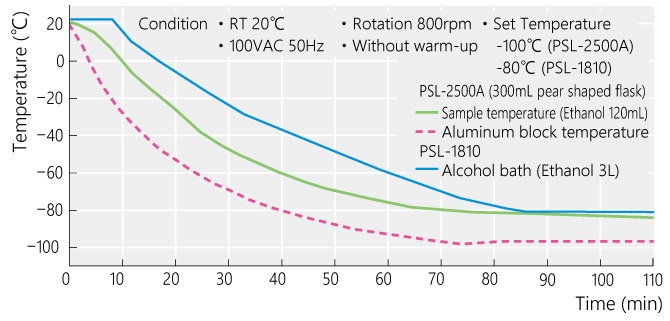

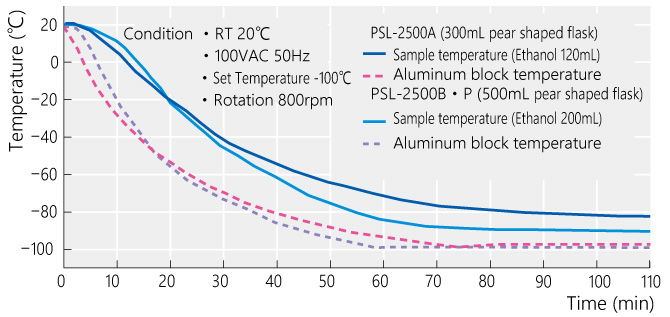

• Cooling curves

• The aluminum block has high heat conductivity and is cooled evenly, so it cools faster than conventional alcohol baths.

♦ Comparison between PSL-2500A and PSL-1810 (Alcohol bath)

♦ Comparison among PSL-2500A・2500B・2500P

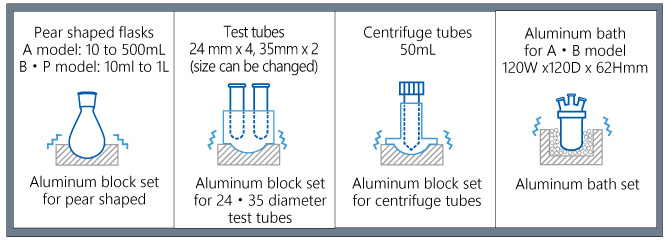

• A wide variety of reaction vessels can be used by selecting appropriate aluminum block sets according to the experimental applications.

Follow these three steps to select the appropriate configuration for your specific needs.

① Select the main unit

| Model | PSL-2500A | PSL-2500B | PSL-2500P |

| Cat. No. | 263150 | 263160 | 269200 |

| Temperature control range | -80 to RT -20℃ | -100℃ to RT (with heater unit -100 to 50℃) |

-100/-80 to 40℃ (with Internal/external temperature control) |

| Temperature control accuracy | Within ±2°C (aluminum block temperature・no load) |

Within ±0.5℃ (ethanol 200mL:sample temperature) |

|

| Cooling capacity | 20℃→-80℃ (approx. 30min) | 20℃→-100℃ (approx. 40min) | 20℃→-80℃ (approx.110min) ※with external temperature sensor |

| Rotation range | 100 to 800rpm | ||

② Select the type of reaction vessels to be used

We offer a wide variety of vessels to accommodate various experiments. When purchasing the main unit, please select the appropriate reaction vessels (optional) based on your intended use.

▶▶▶ Introductory video for the selection of aluminum blocks and adapters according to the vessel types

③ Select aluminum block sets according to the type of reaction vessels selected above

• Aluminum block sets for pear shaped flasks (JIS Standards)

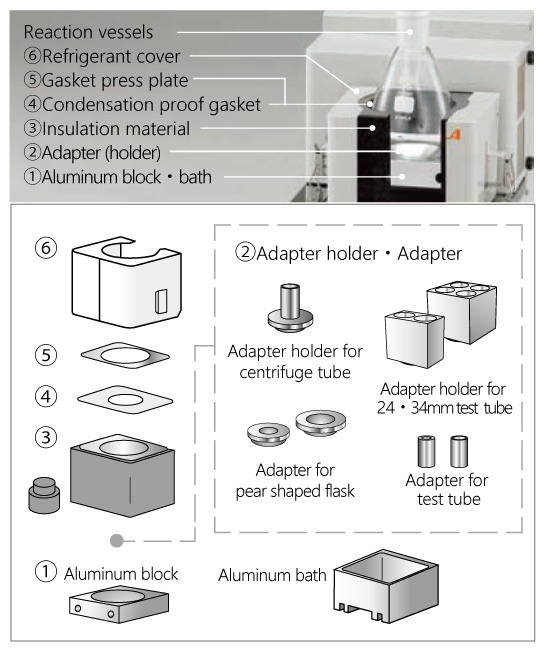

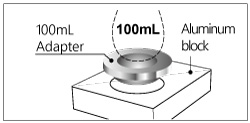

♦ Set configuration

①Aluminum block ②Adapter for pear shaped flask (A model: for 10 to 200mL, B model: for 10 to 300mL) ③Refrigerant ④Refrigerant cover ⑤Condensation-proof gasket ⑥Gasket press plate, heater unit (heater-equipped only)

| Compatible model | For PSL-2500A | For PSL-2500B | For PSL-2500B・P (heater unit included) |

| Size | Cat. No. | Cat. No. | Cat. No. |

| 10mL | 262510 | 262590 | 262730 |

| 20mL | 262500 | 262580 | 262720 |

| 30mL | 262490 | 262570 | 262710 |

| 50mL | 262480 | 262560 | 262700 |

| 100mL | 262470 | 262550 | 262690 |

| 200mL | 262460 | 262540 | 262680 |

| 300mL | 262450 | 262530 | 262670 |

| 500mL | 259630 | 262520 | 262660 |

| 1000mL | - | 258800 | - |

• Adapter sets for pear shaped flasks

After purchasing the set with the pear shaped flasks, test tubes, and centrifuge tubes, you can change the flask size or switch from test tubes/centrifuge tubes to a flask by purchasing the pear shaped flask adapter set. This adapter set is not compatible with the 500mL aluminum block.

♦ Set configuration

①Aluminum block ②Adapter for each size ③Refrigerant ④Condensation-proof gasket ⑤Gasket press plate for each size

| Compatible model | For PSL-2500A aluminum block | For PSL-2500B aluminum block | For PSL-2500B・P (with heater unit) aluminum block |

| Size | Cat. No. | Cat. No. | Cat. No. |

| 10mL | 259450 | 259540 | 267280 |

| 20mL | 259440 | 259530 | 267270 |

| 30mL | 259430 | 259520 | 267260 |

| 50mL | 259420 | 259510 | 267250 |

| 100mL | 259410 | 259500 | 267240 |

| 200mL | 259400 | 259490 | 267230 |

| 300mL |

- | 259830 | 267220 |

• Aluminum block sets for test tubes

♦ Set configuration

①Aluminum block ②Test tube adapter holder (24 or 34mm diameter) ③Refrigerant ④Refrigerant cover ⑤Condensation-proof gasket ⑥Gasket press plate, heater unit (heater-equipped only)

| Compatible model | PSL-2500A | PSL-2500B | PSL-2500B・P (with heater unit) |

| Size | Cat. No. | Cat. No. | Cat. No. |

| 24mm diameter x 4 pcs | 262600 | 262630 | 262740 |

| 34mm diameter x 2 pcs | 262610 | 262640 | 262750 |

• Test tube adapters

If you wish to change the size for 24mm or 34mm diameter test tubes, you can do so by purchasing additional test tube adapters.

Note: The price is for a single test tube adapter. Please purchase the necessary quantity based on the number of test tube adapter holders.

| For PSL-2500A・B・P | |||||

| Size | Cat. No. | Size |

Cat. No. | ||

| 24mm diameter → | 12mm | 259660 | 34mm diameter → | 18mm | 212850 |

| 34mm diameter → | 30mm | 212900 | 16.5mm | 212840 | |

| 25mm | 212890 | 16mm | 212830 | ||

| 24mm | 212880 | 15mm | 212820 | ||

| 21mm | 212870 | 13mm | 212810 | ||

| 20mm | 212860 | 12×4mm | 217080 | ||

• Aluminum block set for 50mL centrifuge tubes

♦ Set configuration

①Aluminum block ②Centrifuge tube adapter holder ③Refrigerant ④Refrigerant cover ⑤Condensation-proof gasket ⑥Gasket press plate, heater unit (heater-equipped only)

| Compatible model | PSL-2500A | PSL-2500B | PSL-2500B・P |

| Size | Cat. No. | Cat. No. | Cat. No. |

| 50mL | 262620 | 262650 | 262760 |

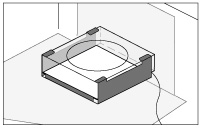

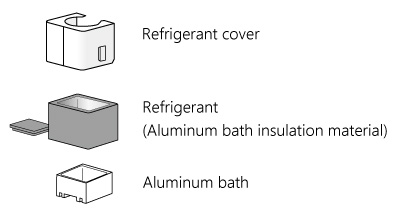

• Aluminum bath sets (dedicated for PSL-2500A・B)

The aluminum bath can be used by inserting reaction vessels of various shapes by placing aluminum beads inside the bath.

♦ Set configuration

Adding PP balls further reduces condensation and freezing during continuous operation. It can also be used as a liquid bath by filling it with low-temperature heat transfer media.

| Product name | Cat. No. |

| Aluminum bath set for PSL-2500A

(96W x 96D x 62H mm) |

265690 |

| Aluminum bath set for PSL-2500B

(120W x 120D x 62H mm) |

262210 |

| Aluminum beads for aluminum bath set(2L) | 262250 |

| PP balls for aluminum bath set, 500 pcs (10mm diameter) | 262260 |

| PP balls for aluminum bath set, 1000 pcs (10mm diameter) | 262270 |

▶▶ Introductory video for the aluminum bath set PSL-2500A and 2500B

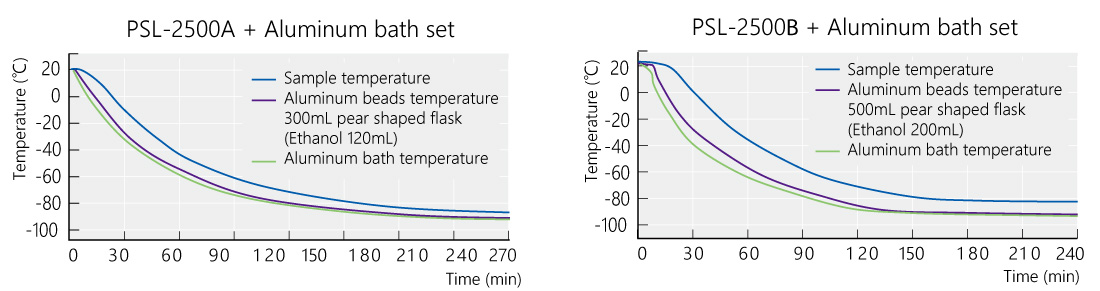

• Cooling curves (Aluminum beads + PP balls)

• Specifications

| Product name | Aluminum Block Dry Bath with Magnetic Stirrer | ||

| Model | PSL-2500A | PSL-2500B | PSL-2500P |

| Cat. No. | 263150 | 263160 | 269200 |

| Heating method | - | Heater heating (optional) | Heater heating |

| Cooling method | Cooling by aluminum block | ||

| Temperature control range | -80 to 20℃ | -100℃ to RT Option: with heater unit -100 to 50℃ | -100/-80 to 40℃ (internal/external temperature control) |

| Temperature control accuracy | Within ±2°C (Aluminum block temperature・no load) | Within ±2°C (Aluminum block temperature・no load) | Within ±0.5℃(Ethanol 200mL: sample temperature) |

| Temperature setting range | -100 to 20℃ | -100 to 50℃ | -100 to 40℃ |

| Time to reach minimum temperature | 20℃ → -80℃ (approx. 30min) | 20℃ → -100℃ (approx. 40min) | 20℃ → -80℃ (approx.110min: With external temperature sensor) |

| Rotation speed range | 100 to 800rpm | ||

| Temperature control | PID control | PID control, Cascade control | |

| Setting・display | Membrane keypad input, minimum setting digit 1°C, digital setting ・display | ||

| Program function | - | - | Ramp program (max. 8 segments) |

| Additional features | External temperature sensor (option) | External temperature sensor (option), Heater unit (option) | External temperature sensor (standard accessory), Heater unit |

| Safety features | Earth leakage・overcurrent breaker, upper limit setting for cooling unit exhaust temperature, and cooling unit output restriction (when the set temperature is above -20°C). | Earth leakage・overcurrent breaker, upper limit setting for cooling unit exhaust temperature | |

| Temperature sensor | Platinum resistance thermometer Pt100Ω | Platinum resistance thermometer Pt100Ω, External temperature sensor | |

| Heater | - | 50W (option) | 50W |

| Motor | Brushless DC motor output 15W | ||

| Refrigerator ・refrigerant | Stirling cooler 80W・helium (non-fluorocarbon) | Stirling cooler150W・helium (non-fluorocarbon) | |

| Aluminum block set | Sold separately | ||

| Exterior | Bonded steel plate, melamine resin baked coating | ||

| Ambient temperature range | 5 to 35℃ | ||

| Power input | 1.5A, 150VA | 2.5A, 250VA | 3A, 300VA |

| Supply voltage | 100VAC 50/60Hz | ||

| Outer dimensions (mm) | 220W x 445D x 315H | 220W x 600D x 355H | 220W x 600D x 405H |

| Weight | Approx. 15kg | Approx. 24kg | Approx. 24kg |

| Accessories | Condensation tray, Teflon® stirring bar 20mm, External temperature sensor | ||

| Annotation | ※Performance values are based on room temperature of 20°C, rated power supply voltage, 50Hz, 800rpm, stirring in the bath and no load. ※Aluminum block set is sold separately. ※When using the pear-shaped flask aluminum block set, the minimum ultimate temperature is -70°C for the PSL-2500A (500mL) and -80°C for the PSL-2500B・P (1L). |

||

| Annotation (model specific) | - | ※Minimum ultimate temperature is -80°C. When controlling the sample temperature with an external or sample temperature sensor, do not set the temperature lower than -80°C. | ※Temperature control range・accuracy are values when the heater unit of the aluminum block set is used. ※The minimum ultimate sample temperature is -80°C. When controlling the sample temperature with the external ・sample temperature sensor, do not set the temperature lower than -80°C. |

• Options

| Product name | Description | Cat. No. |

| External temperature sensor (SUS)

|

The sample temperature can be monitored. With PSL-2500B, temperature control of the sample inside the container is possible. Note: PSL-2500P includes this feature as standard. |

203550 |

| Teflon® sample temperature sensor

|

Suitable for monitoring the temperature of samples, including acid-based solvents. With PSL-2500B, temperature control of the sample inside the container is possible. | 260110 |

| Pole set

|

The pole attaches to the side of the main unit, allowing secure mounting of droplet tubes or reaction vessels.

Set configuration: Pole (10mm diameter x 495mm), Pole holder |

259580 |

| Heater unit for PSL-2500B

|

Use for controlling temperatures above room temperature (temperature control range: Max. 50°C), defrosting, or heating from extremely low temperatures. | 260260 |

▶▶ Introductory video for the heater unit