• Models UT-1000 and UT-2000

• Effectively captures hazardous vapors with a space-saving design optimized for installation inside a fume hood

♦ Efficiently captures water vapor and harmful gases discharged from vacuum dryers and concentrators through the vacuum line, significantly reducing vapor load on the vacuum pump and extending its lifespan.

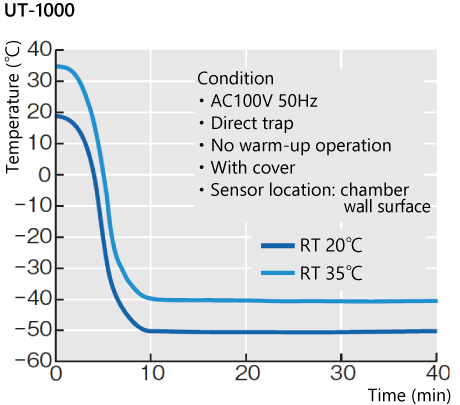

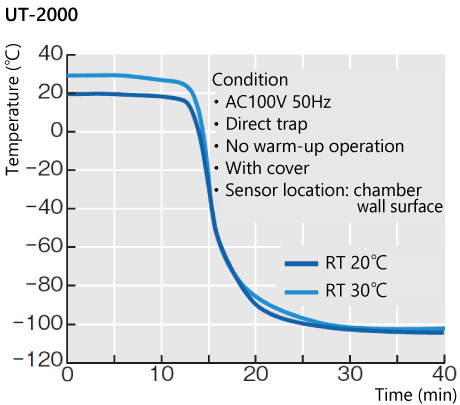

♦ The minimum ultimate temperatures of UT-1000 and UT-2000 are -50°C and -100°C, respectively, allowing for efficient capture of harmful vapors.

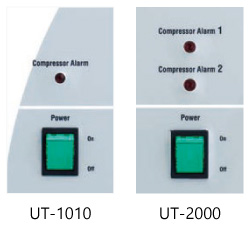

• Simple control panel

Abnormal refrigerator conditions, such as overload operation, can be visually identified via the LED indicator.

• A diaphragm vacuum pump can be mounted on the top section to maximize space efficiency

♦ Suitable for trapping steam exhausted from 1L rotary evaporators, centrifugal evaporators, etc.

♦ A cover with nozzle is available for trapping aqueous vapors. For acid and organic solvent vapor traps, options include the glass condenser set or the aluminum block set, which enables chamber cooling without using brine.

• The chamber cooling method allows easy drainage of trapped liquid and facilitates cleaning

No cooling coil is used in the trap chamber.

▶▶▶ Introduction to the necessity of cold traps

• Specification

| Product | Cold Trap | |||

| Model | UT-1000 |

UT-2000 |

||

| Cat. No. | 189207 | 189208 | 189218 | 189219 |

| Cooling method | Direct trap with chamber cooling method, glass condenser |

|||

| Dehumidifying volume | Max. 0.5kg (water) |

Max. 0.4kg (water) |

||

| Minimum ultimate temperature | -50°C |

-100°C |

||

| Safety features | Earth leakage・overcurrent breaker, Refrigerator overload relay, Refrigerator high-pressure switch |

|||

| Refrigerator・refrigerant | Air-cooled output 400W, R452A |

Air-cooled output 450W+450W, R404A/R1150 |

||

| Built-in outlet | Max.4A for diaphragm pumps |

Max. 2A for diaphragm pumps |

||

| Bath sizes (mm)・capacity | 90 ID x 225H・approx. 1.4L |

|||

| Ambient temperature range | 5 to 35°C |

5 to 30°C |

||

| Outer dimensions (mm) | 380(420)W x 370D x 317H |

420(460)W x 510D x 475H |

||

| Weight | Approx. 27kg |

Approx. 56kg |

||

| Power input | 2A, 0.5kVA | 3A, 0.7kVA | 8A, 1.3kVA | 12A, 1.3kVA |

| Supply voltage | 220VAC 50Hz | 220VAC 60Hz | 220VAC 50Hz | 115VAC 60Hz |

♦ The cover with nozzle, glass condensers, and glass condensers for low boiling point solvents are sold separately.

♦ The performance is based on room temperature of 20°C, with the rated power supply voltage at 50Hz, and the minimum ultimate temperature indicates the temperature of the wall surface inside the chamber.

♦ The power input value does not account for the load of the built-in outlet.

♦ Power supply voltage is the power supply capacity when using the built-in outlet.

♦ Dimensions in parentheses ( ) include protrusions.

♦ This product is not intended for use as a freeze dryer.

• Data

• Cooling curve

• Options

• Cover with nozzles

♦ Used for vapor trapping of aqueous samples in combination with the cold trap. Made of stainless steel. The material of the nozzle part on the load side of the cover B2 with nozzle is Teflon®.

♦ When performing vapor trapping for aqueous samples, the cold trap is required with the cover with nozzle.

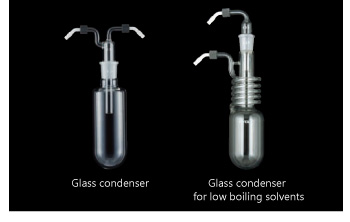

• Glass condensers

♦ Used for trapping acid and organic solvent vapors in the cold trap. Hard glass that is resistant to low temperature environments is used, so it can withstand environments of -100°C.

♦ Used for trapping acid and organic solvent vapors in the cold trap. Hard glass that is resistant to low temperature environments is used, so it can withstand environments of -100°C.

♦ The glass condenser for low boiling solvents allows the vapor to first pass through the spiral tube, increasing the contact (heat exchange) area with the low-temperature section, thereby improving recovery efficiency.

Note: This is not suitable for high boiling solvents or those with a freezing point above the trap temperature, as freezing and blockage may occur inside the spiral tube.

♦ The nozzle cap is installed at the connection between the glass condenser and the vacuum hose, making it easy to connect the vacuum hose. The material of the nozzle cap is PP, and the O-ring is made of PFA, which offers excellent corrosion resistance.

♦ Composition of glass condenser set B: Glass condenser, pole, clamp, muff, PVC chamber cover

• Covers with nozzle and glass condensers

| Product | Compatible model | Characteristics | Connection diameter (mm) | Dehumidifying volume | Cat. No. |

| Cover B with nozzle | For UT-1000 | Direct collection of aqueous vapor in the chamber | 10 | Max.0.5kg | 192410 |

| Cover B2 with nozzle | For UT-2000 | 10 | Max.0.4kg | 193600 | |

| Glass condenser | For UT-1000・2000 | Collects acid and organic solvent vapors | 10 | 500mL | 199700 |

| Glass condenser set B | For UT-100・2000 | 10 | 500mL | 199740 | |

| Glass condenser for low boiling point solvents | For UT-1000・2000 | Efficiently collects low boiling point organic solvent vapors | 10 | 500mL | 199710 |

| Glass condenser set B for low boiling point solvents | For UT-1000・2000 | 10 | 500mL | 199750 |

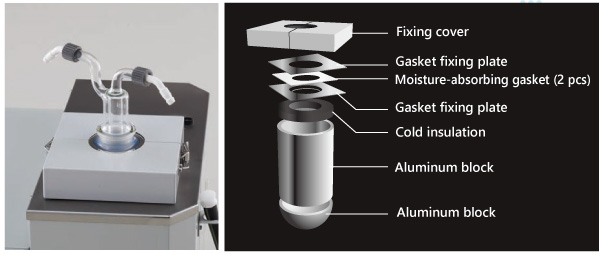

• Aluminum block set

| Product | Aluminum block set (for UT-1000・2000) |

| Cat. No. | 266170 |

| Designed exclusively for the glass condenser (Cat. No. 199700) | |

♦ This is the aluminum block set exclusively for the UT-1000 and 2000 cold traps, allowing the trap chamber to be cooled using an aluminum block instead of brine (alcohol-based heat medium) when collecting acid or organic solvent vapors with glass condensers.

♦ Since brine is not used, there is no need for brine replenishment or replacement, allowing for a clean and highly safe research environment.

♦ Can be used in laboratories where the use of hazardous solvents such as ethanol is prohibited.

♦ The glass condenser (Cat. No. 199700) can be directly placed into the aluminum block, eliminating the need for clamp operation and ensuring easy setup.

♦ The coldest part is covered with the cold insulation, which significantly reduces the amount of condensation.

• Stand with casters, vacuum hoses and adapters

| Product | Standard | QTY | Cat. No. |

Stand with casters |

For UT-1000 | 1 | 192420 |

| For UT-2000 | 1 | 192430 | |

Vacuum hose  |

18 ID x 42 OD (mm) | 5m | 119230 |

| 12 ID x 30 OD (mm) | 5m | 119210 | |

| 9 ID x 21 OD (mm) | 5m | 119190 | |

| 6 ID x 15 OD (mm) | 5m | 119170 | |

Adapter A  |

22 OD x 17 OD (mm) | 1 | 119240 |

| Adapter B | 17 OD x 13 OD (mm) | 1 | 119250 |

| Adapter C | 17 OD x 10 OD (mm) | 1 | 119260 |

| Adapter D | 22 OD x 13 OD (mm) | 1 | 119270 |

| Adapter E | 13 OD x 10 OD (mm) | 1 | 119280 |

| Adapter F | 22 OD x 10 OD (mm) | 1 | 191660 |