• Models UT-3000A, UT-3010L, UT-4000A and UT-4000L

• Two dehumidifying capacities are available: 1kg (Model A) and 4kg (Model L), with a digital trap temperature display and a variety of advanced features

• Utilizes a chamber cooling system that facilitates easy drainage of trap liquid and simplifies internal cleaning

Equipped with a defrost function for easy de-icing and removal, facilitating drainage of trap liquid and simplifying cleaning.

• Equipped with a drain valve for easy drainage

• Vacuum hose fixture included as standard

The nozzle section of the optional transparent cover with nozzle can rotate 360°, allowing connection without applying bending stress to the vacuum hose. It also enables a compact arrangement of the connecting tubing.

• Trap temperature is displayed in 5°C increments

The temperature display indicates the appropriate timing to start the oil rotary vacuum pump, helping to prevent moisture from being drawn into the piping. It also allows for monitoring the operational status of the equipment.

• Vacuum pump control unit manages the oil rotary vacuum pump (optional)

The vacuum pump can be operated or stopped using the main unit’s vacuum pump switch. Additionally, the vacuum pump operation is linked to the total operation timer, providing a reference for oil replacement in the oil rotary vacuum pump.

•Monitor trap saturation with the optional trap monitor (optional)

By using it in conjunction with the optional transparent cover with nozzle, a lamp indicates when the trap chamber is nearing saturation before reaching the maximum dehumidification capacity.

This is useful for continuous use, such as during prolonged concentration with a vacuum dryer or evaporator. It also helps protect the vacuum pump.

▶▶▶ Introduction to the necessity of cold traps

• Specification

| Product | Cold Trap | ||||||

| Model | UT-3000A |

UT-3010L | UT-4000A |

UT-4000L |

|||

| Cat. No. | 216158 | 216159 | 279990 | 216178 | 216179 | 216188 | 216189 |

| Cooling method | Chamber cooling method (glass trap: optional, direct trap) |

||||||

| Dehumidifying volume | Max. 1kg (water) |

Max. 4kg (water) | Max. 1kg (water) |

Max. 4kg (water) |

|||

| Ultimate temperature | -50°C |

-80°C |

|||||

| Temperature sensor | T thermocouple |

||||||

| Safety features | Earth leakage・overcurrent breaker, High pressure switch (refrigerator cycle), Refrigerator overload relay, Self-diagnostic functions (refrigerator error, power failure alarm, sensor error) |

||||||

| Other functions | Trap temperature display, Defrost function, Vacuum pump operation switch (vacuum pump control output) user adjustment mode (display temperature compensation, power failure return setting), Trap chamber saturation detection function (option) |

||||||

| Display・resolution | Trap temperature (digital display)・5°C |

||||||

| Refrigerator・refrigerant | Air-cooled output 450W・HFC R-404A |

Air-cooled output 650W・HFC R452A | Air-cooled output 450W x 2・primary: R404A, secondary: R23 (HFC) |

||||

| Cover with nozzle | Transparent cover with nozzle (acrylic), stainless steel cover with nozzle | ||||||

| Connection port diameter | Suction・exhaust 17.3mm OD |

Suction・exhaust 21.7mm OD | Suction・exhaust 17.3mm OD |

Suction・exhaust 21.7mm OD |

|||

| Trap chamber material | Stainless steel |

||||||

| Glass condensers | Glass condenser set C, Large volume glass condenser set C, Glass condenser set C for low boiling point solvents, Glass condenser with handle, Large volume glass condenser with handle, Glass condenser for low boiling point solvents with handle |

||||||

| Chamber sizes (mm) | 153 ID x 225H |

200 ID x 310H | 153 ID x 225H |

200 ID x 310H |

|||

| Capacity | Approx. 3.9L |

Approx. 9.1L | Approx. 3.9L |

Approx. 9.1L |

|||

| Ambient temperature range | 5 to 35°C |

||||||

| Power input | 3.2A, 700VA |

6.1A, 700VA | 10A, 1kVA | 5.9A, 1.3kVA | 11.3A, 1.3kVA | 6.8A, 1.5kVA | 13A, 1.5kVA |

| Supply voltage | 220VAC 50Hz | 115VAC 60Hz | 100VAC 50/60Hz | 220VAC 50Hz | 115VAC 60Hz | 220VAC 50Hz | 115VAC 60Hz |

| Outer dimensions (mm) | 300(335)W x 350(362)D x 835(1009)H |

340(372)W x 370(382)D x 835(1009)H | 330(362)W x 470(482)D x 835(1009)H |

340(377)W x 520(532)D x 835(1009)H |

|||

| Weight | Approx. 33kg |

Approx. 42kg | Approx. 60kg |

Approx. 65kg |

|||

♦ The values are based on an ambient temperature of 20°C and power supply of 100VAC 50/60Hz.

♦ The dimensions in parentheses ( ) include protrusions.

♦ The connection port diameter indicates the nozzle diameter of the trap chamber cover.

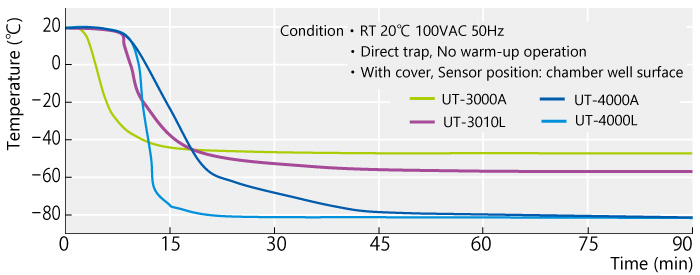

• Data

• Cooling curve

• Options

• Vacuum pump control unit

The vacuum pump can be operated or stopped using the main unit’s vacuum pump switch. Additionally, the vacuum pump operation is linked to the total operation timer, providing a reference for oil replacement in the oil rotary vacuum pump.

• Trap monitor

By using it in conjunction with the optional transparent cover with nozzle, a lamp indicates when the trap chamber is nearing saturation before reaching the maximum dehumidification capacity.

This is useful for continuous use, such as during prolonged concentration with a vacuum dryer or evaporator. It also helps protect the vacuum pump.

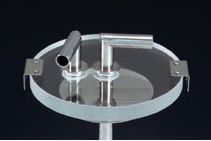

• Transparent cover with nozzle (acrylic)

♦ Used with the UT-3000 and 4000 series as a vapor trap for aqueous samples.

♦ The inside of the trap chamber can be monitored at any time without releasing the vacuum inside the chamber.

♦ The nozzle section can rotate 360°, allowing connection without bending stress on the vacuum hose.

♦ The cover holder is included so that the cover does not fall off the equipment after the vacuum is released.

♦ By using it in combination with the optional trap monitor, you can be alerted by an alarm when the trap liquid becomes saturated.

• Cover with nozzle (stainless steel)

♦Used with the UT-3000 and 4000 series as a vapor trap for aqueous samples.

♦The cover holder is included so that the cover does not fall off the equipment after the vacuum is released.

♦ The cover is not transparent, so the inside of the chamber cannot be visually monitored during operation.

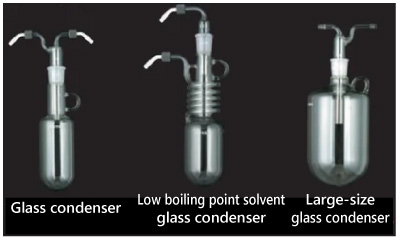

• Glass condensers

♦ It is used for trapping acidic and organic solvent vapors with the cold traps.

♦ It is made of durable, hard glass that is resistant to low temperatures, allowing it to withstand environments as low as -100°C.

♦ Made of durable hard glass resistant to low temperatures, suitable for use down to -100°C. In glass condensers for low boiling point solvents, the vapor first passes through the spiral tubing, increasing the contact (heat exchange) area with the low temperature area and improving recovery efficiency.

♦ This product cannot be used with high boiling solvents or solvents with a freezing point higher than the trap temperature, as there is a risk of freezing and blockage inside the spiral tubing.

♦The nozzle cap is installed at the connection point between the glass condenser and the vacuum hose, making it easy to connect to the vacuum hose. The nozzle cap is made of PP and the O-ring is made of Perfluor. It has excellent corrosion resistance.

♦ Composition of the glass condenser set C: Glass condenser, Pole, Clamp, Muff, and PVC chamber cover.

| Product | Compatible model | Standard | Connection port (mm) | Dehumidifying volume (water) | Cat. No. |

Transparent cover with nozzle (rotating nozzle structure) |

UT-3000A・4000A | Cover: Made of acrylic | 17.3 | 1.0kg | 216210 |

| UT-3010L・4000L | 20 | 4.0kg | 216220 | ||

Cover A with nozzle |

UT-3000A・4000A | Cover: Made of stainless steel | 17.3 | 1.0kg | 148940 |

| UT-3010L・4000L | 20 | 4.0kg | 185890 | ||

| Glass condenser set C | UT-3000A・4000A (Configuration: glass condenser, pole, clamp, muff, PVC chamber cover) |

Standard | 10 | 500mL | 217540 |

| Glass condenser set C for Low boiling point solvent | For low boiling point solvents | 10 | 500mL | 217560 | |

| Large-size glass condenser set C | UT-3010L・4000L (Configuration: glass condenser, pole, clamp, muff, PVC chamber cover) |

For large size | 10 | 1800mL | 217580 |

Glass condenser |

For glass condenser set C | 80mm diameter x 332H | 10 | 500mL | 217510 |

Glass condenser for Low boiling point solvent |

For glass condenser set C for low boiling point solvents | 80mm diameter x 340H | 10 | 500mL | 217520 |

Large-size glass condenser |

For large-size glass condenser set C | 150mm diameter x 375H | 10 | 1800mL | 182470 |

• Hoses and adapters

| Product | Standard (mm) | Length/QTY | Cat. No. |

Vacuum hose  |

18 ID x 42 OD | 5m | 119230 |

| 12 ID x 30 OD | 5m | 119210 | |

| 9 ID x 21 OD | 5m | 119190 | |

| 6 ID x 15 OD | 5m | 119170 | |

Adapter A |

22 OD x 17 OD | 1 | 119240 |

| Adapter B | 17 OD x 13 OD | 1 | 119250 |

| Adapter C | 17 OD x 10 OD | 1 | 119260 |

| Adapter D | 22 OD x 13 OD | 1 | 119270 |

| Adapter E | 13 OD x 10 OD | 1 | 119280 |

| Adapter F | 22 OD x 10 OD | 1 | 191660 |