![]()

• Models KCL-2000A and KCL-2000W

• Programmed ramp control of temperature and humidity, ideal for environmental testing, storage tests, and culture

• Ideal for various degradation, accelerated, and environmental tests

♦ Provides a wide range and high-precision temperature and humidity control from -15 to 85°C and 25 to 98% RH, with a ramp program for precise test environments.

♦ Equipped as standard with a recorder output terminal, alarm output terminal, and RS-232C communication terminal.

♦ Software for processing trend data for each parameter is included.

♦ Despite its compact, space-saving design, it offers a generous internal capacity of 140 liters.

♦ The display indicates when to replace the wet bulb wick and when to clean the humidifying pan. Maintenance can be easily performed from the front panel.

♦ Antibacterial tubing is used for piping to inhibit the growth of bacteria.

♦ A stand with casters is equipped as standard. If a drainage facility is unavailable, an optional drain tank can be installed without occupying additional space.

♦ KCL-2000W is equipped with a large observation window. To prevent condensation on the observation window, a heating wire is embedded inside the glass.

• Enhanced safety features

◊ Centralized alarm monitoring function

Dry bulb temperature sensor failure, Wet bulb temperature sensor failure, Heater malfunction, High-pressure refrigerator anomaly, Refrigerator overload, Temperature ramp failure, Power failure, Overheating, Overcooling, Cooling failure, Water level sensor failure, Humidity control failure, Excessive humidity, Flow anomaly, Water supply tank depletion, Door open, Watchdog malfunction, SSR failure, Variable independent overheat protector, Earth leakage/overcurrent breaker

• Enhanced communication functions, supporting validation

◊ Equipped with standard recorder output, alarm output terminals, and RS-232C communication terminals

The internal temperature and humidity can be output, enabling immediate notification to a central control panel or activation of a warning light in the event of an abnormality. RS-232C communication allows operational status to be managed by a computer, supporting validation.

• Easy-to-operate lever lock (Improved from October 2024 shipment)

It can be opened and closed easily without applying force. The handle does not protrude, so you can use it safely without worrying about your clothes getting caught.

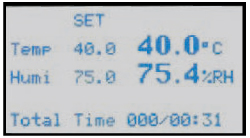

• Easy-to-understand display

♦ Setting mode

The set temperature and humidity, measured temperature and humidity, and cumulative operating time are displayed simultaneously.

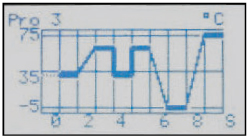

♦ Graphic mode

The progress of the program can be checked graphically.

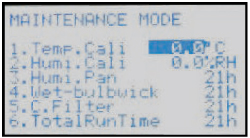

♦ Maintenance mode

The cumulative operating time of the humidifying pan and the wet-bulb wick is displayed, allowing easy monitoring of maintenance schedules. The total operating time of the equipment is also shown.

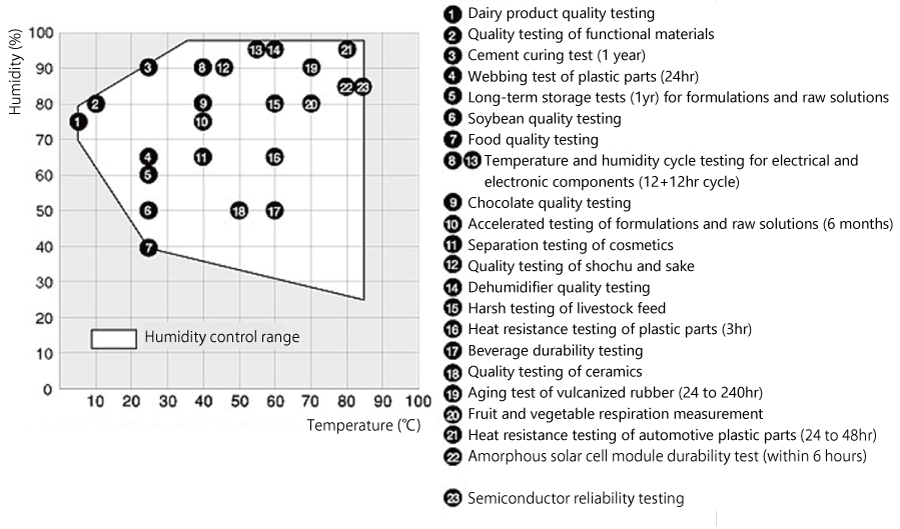

• Examples of major applications

♦ The temperature control range varies slightly depending on the ambient environment and installation conditions.

♦ When operating for an extended period (24 hours or more) at a set temperature of 25°C or lower, it is necessary to configure the interval defrost setting. During defrosting, both the internal temperature and humidity will increase.

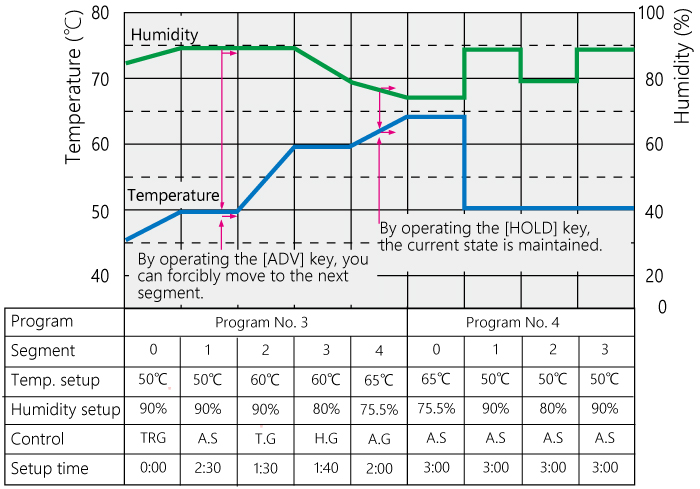

• Operation patterns

• Programmed operation function

| Segments | Up to 10 segments per pattern |

| Programmed repetitive operation | 1 to 999 times or infinite |

| Control functions | Target value priority control of temperature and humidity, step control, ramp control |

| Auto-start program | Automatic start |

| Auto-stop program | Automatic stop |

| User program | 7 types (up to 10 segments each) |

| Auto-start and user linking program | Two programs linked |

| Consolidated programs | Up to six user programs can be consolidated |

• Example of program pattern(KCL-2000)

Control types: TRG (Target temperature priority control), A.S (Step control of temperature and humidity), T.G (Temperature ramp, constant humidity control), H.G (Constant temperature, humidity ramp control), A.G (Temperature and humidity ramp control)

• Specification

| Product | Environmental Chamber | ||

| Model | KCL-2000A | KCL-2000W | |

| Cat. No. | 204580 | 204590 | 204598 |

| Convection | Forced convection system | ||

| Temperature control range | -15 to 85°C | ||

| Temperature control accuracy | ±0.5°C | ||

| Temperature distribution accuracy | ±2°C | ||

| Temperature control | PID control | ||

| Humidity control range | 25 to 98% RH | ||

| Humidity control accuracy | ±3% RH | ||

| Humidity distribution accuracy | ±6% RH | ||

| Humidity control | PID control | ||

| Dehumidification method | Normal operation: Automatic control (interval defrost mode), Forced manual operation (manual start, automatic stop・manual stop) | ||

| Setting・display | Membrane keypad input・digital setting, digital display, minimum digit 0.1°C/0.1%RH | ||

| Program functions | Auto-start program, auto-stop program, user program (7 patterns) | ||

| Safety functions | Centralized alarm monitoring function, Dry bulb temperature sensor failure, Wet bulb temperature sensor failure, heater error, Refrigerator high-pressure error, Refrigerator overload operation, Temperature ramp failure, Power failure, Overheat, Overcool, Cooling failure, Water level sensor failure, Humidity control failure, Humidity upper limit failure, Flow error, Water supply tank empty, Door open, Watchdog, SSR failure, Variable independent overheat protector, Earth leakage/overcurrent breaker | ||

| External input・output | RS-232C connection terminal, Temperature・humidity recorder output terminal (temperature 1℃/mV, humidity 1% RH/mV)・Output: -200 to 200mV, Alarm output terminal (contact・voltage free contact, contact point capacity 250VAC 5A OFF in normal operation, ON in abnormal operation) | ||

| Other features | Calibration of temperature・humidity displays, External water supply, Maintenance mode, Forced drainage | ||

| Observation window sizes (mm) | ̶ | 200W x 540H・Quadruple glass (with heater) | |

| Interior | Stainless steel | ||

| Heater | Heating heater: 650W, Humidifying heaters: 200W and 400W | ||

| Temperature sensor | Platinum resistance thermometer (Pt100 ohms) | ||

| Refrigerator・refrigerant | Air-cooled, Output 160W・R134a | ||

| Inner chamber dimensions (mm) | 500W×400D×700H | ||

| Inner chamber capacity | 140L | ||

| Shelf load capacity | Uniform load max. 15kg/shelf | ||

| Shelf material | Stainless steel | ||

| Number of shelf boards included | 2 pcs | ||

| Shelf pitch・number of max. shelf boards | 40mm・10 shelves | ||

| Cable port | One on the right side, 40mm ID | ||

| Water tank capacity | Internal: approximately 10L (removable from the front) External: approximately 20L (connects with a one-touch socket) |

||

| Water supply | Distilled/purified water or ion-exchanged water (polyethylene tank or cartridge purifier), electrical conductivity less than 10 μS/cm | ||

| Drain port | 11mm OD x 7mm ID | ||

| Ambient operating temperature | 5 to 35°C | ||

| Power input・supply voltage | 15A, 1.5kVA・100VAC 50/60Hz | 7A, 1.5kVA・220VAC 50Hz | |

| Outer dimensions (mm) | 635(800)W x 777D x 1695H (including stand) 600(800)W x 777D x 1285H (main unit) |

||

| Weight | Approx. 145kg | Approx. 153kg | |

| Accessories | External water tank (20L) x 1, Tank stand x 1, Water supply and drainage hoses (1m each), Silicone plug for cable hole x 1, Alarm output connector x 1, RS-232C communication cable x 1, etc. | ||

♦ The minimum・maximum ultimate temperatures, temperature・humidity control accuracy, and temperature・humidity distribution accuracy depend on operating conditions such as room temperature, heat load conditions, and supply voltage.

♦ During the defrost operation, the internal temperature will increase by -2°C to +2°C (approximately 3°C), and the internal humidity will rise by approximately 30% RH. The amount of change depends on the conditions of use.

♦ At an ambient temperature of 35°C, the minimum achievable internal temperature is -10°C.

♦ Dimensions in parentheses ( ) include protrusions.

• Factory option product with recorder

The recorder used is the μR-10000 model. Various settings for the recorder are configured at the factory before shipment. The recorder unit is externally mounted on the equipment.

| Product | Cat. No. |

| KCL-2000A with μR-10000 | 218690 |

| KCL-2000W with μR-10000 | 218700 |

• Options

| Product | Remark | Cat. No. |

Recorder μR-10000 (for KCL-2000A・W)  |

6 measurement points, inputs VDC, TC, RTD, DCA, recording paper type | 219250 |

| Recorder output cables | Two required (one each for temperature and humidity) | 147570 |

| Shelf board | ̶ | 241630 |

| Shelf board support | ̶ | 204980 |

| Cable hole plug | ̶ | 170240 |

| Wet-bulb wick (12 wicks) | ̶ | 205190 |

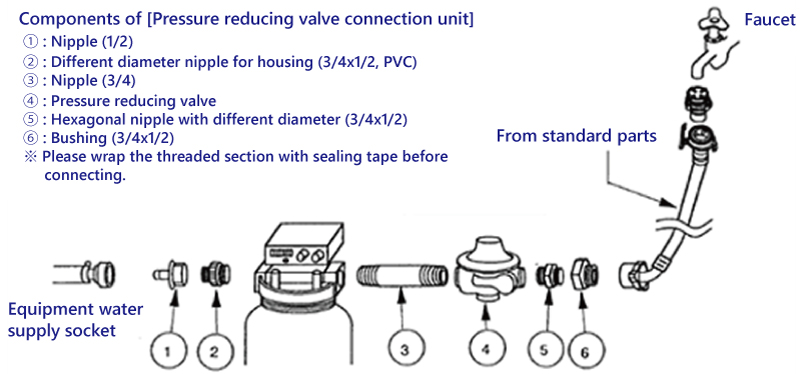

EMR Cartridge-type deionizer |

A cartridge-type pure water system for humidifying water. Note: A pressure-reducing valve connection unit is required for installation. |

̶ |

| EMR-5 (Collection volume: 750 to 1500L/cycle) | ̶ | 276400 |

| EMR-10 (Collection volume: 1500 to 2000L/cycle) | ̶ | 276410 |

| EMR-25 (Collection volume: 3700 to 5000L/cycle) | ̶ | 276420 |

| Connecting hose for EMR | ̶ | 281880 |

| Pressure reducing valve connection unit | This unit is required for connecting to the EMR cartridge deionizer. Please replace the standard part of the EMR before use. | 190860 |

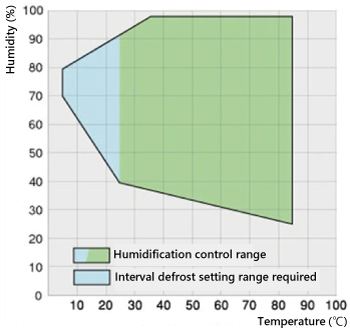

• Data

• Humidification control range

・Conditions

Room temperature 20°C, rated supply voltage, no load in the chamber

♦The temperature control range may vary slightly depending on the surrounding environment and installation conditions.

♦When operating continuously (24 hours or more) at a set area temperature of 25°C or lower, interval defrosting must be configured. During defrosting, both the internal temperature and humidity will rise.

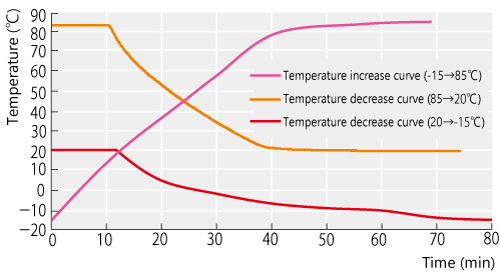

• Temperature increase・decrease curves

・Conditions

・Conditions

No load, no humidification limit, measurement point: center of chamber, no warming operation, room temperature 23°C, 50Hz

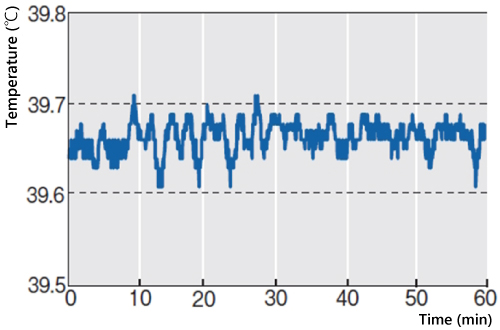

• Temperature control accuracy

・Conditions

・Conditions

Setting 40°C, 75%RH, no load, with compensation, room temperature 23°C, 50Hz

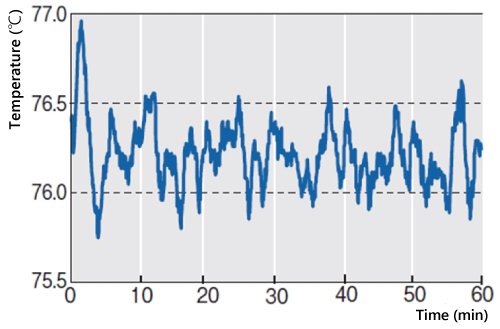

• Humidity control accuracy

・Conditions

Setting 40°C, 75%RH, no load, with compensation, room temperature 23°C, 50Hz