• Auto Jack Type Rotary Evaporators

| N-1210BV-WB | N-1210BS-W | N-1210BT-W |

| Evaporator (driving unit) + Type V vertical double spiral condenser + Water・oil bath | Evaporator (driving unit) + Type S diagonal double spiral condenser + Water bath | Evaporator (driving unit) +Type T Dewar flask condenser + Water bath |

◊ This rotary evaporator features an auto-jack system that allows easy vertical movement of the evaporator (drive unit) through a simple key switch operation.

◊ In the event of a power failure, the system automatically raises the jack, ensuring that valuable samples are not left submerged in the bath.

◊ Even when a trap ball is connected, the height of the drive unit can be adjusted using the manual slide mechanism, providing consistent operability regardless of the flask volume or size of the trap ball.

◊ The up/down key switch is located on the front side of the main body, so even if the rotary evaporator is installed inside a fume hood, it can be operated with only a small opening, minimizing exposure to solvents.

◊ Teflon® vacuum seal is used. It has excellent durability and chemical resistance, and can be used for a long period of time, even when rotating at high speeds.

▶▶▶ As a simple example, let’s try concentrating seawater

• Concentration by vacuum control

♦ Connection with vacuum controller NVC-3000

◊ The controller can display not only the controlled pressure but also the cooling water temperature, bath temperature, rotary evaporator rotation speed, and vapor temperature (sensor sold separately) all at once.

◊ The entire system automatically starts or stops operation in response to the start/stop of the rotary evaporator or vacuum controller. Note: The bath operates only when stopped.

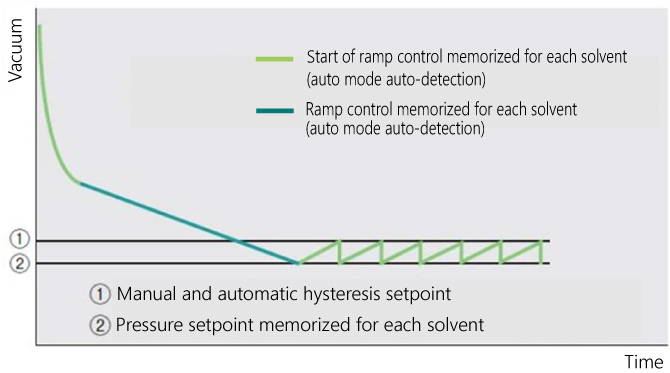

♦ Vacuum control function (during ramp program control)

It features Normal Mode where settings can be changed manually during operation, Auto Mode that detects boiling points, performs ramp control, and sets pressure automatically with just the press of the RUN key, and Program Mode that controls vacuum levels appropriately by selecting the solvent name. These modes ensure optimal vacuum conditions and a high solvent recovery rate.

▶▶▶ Features of the NVC-3000 Vacuum Controller in conjunction with the rotary evaporator

▶▶▶ Comparison of rotary evaporator system with and without NVC-3000 Vacuum Controller

• EYELACOAT® shatterproof coating for glass vessel breakage

♦ The coating material is an eco-friendly polyurethane with a new composition that makes it difficult to break and reduces the scattering of glass and samples in the event of breakage. This composition boasts excellent chemical properties and exceptional transparency, making the coating almost invisible. There is also F type condenser (N-1210BVF) version applied to condensers, adapters, and receiving flasks.

• Designed for improved operability

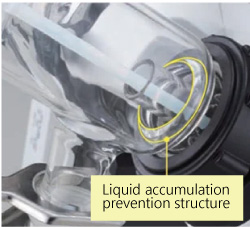

| Liquid accumulation prevention structure | No backflow structure |

|

|

| A liquid accumulation prevention structure has been applied to the receiving flask side to reduce the pooling of liquid that often occurs when the condenser is tilted during use. | The position of the condenser is offset from the capillary, eliminating the risk of condensate from the condenser flowing back through the capillary into the sample flask. |

| Hose holder | Easy connection and disconnection of cooling hose |

|

|

| The hose holder is used to bundle the hoses required for connecting related products to the rotary evaporator. It helps to efficiently utilize the workspace on the laboratory bench. | The condenser and cooling hose can be easily attached and detached by using the optional one-touch connector and one-touch cooling hose set. |

• Combination guide

|

Configuration of Rotary Evaporators You can freely select your desired configuration, incorporating each part described below. • Rotary evaporator (N-1210 model comes with the high performance auto jack type driving unit) • Type V, S or T glass condenser • Water bath or Water・Oil bath |

♦ Select from three (3) types of condensers

| Condenser type |

V type | S type | T type |

| Vertical double spiral condenser | Diagonal double spiral condenser | Dewar flask condenser | |

| Model |

N-1210BV△-∅ |

N-1210BS-∅ | N-1210BT-∅ |

| If it is the shatterproof coating model, “F” is placed in the △. The ∅ contains the bath type | |||

| Features | The vertical condenser is uniquely designed to be space-saving with a small width and to prevent condensate from flowing back through the capillary to the sample flask. It is effective for concentrating analytical samples and other samples that should not be contaminated. The shape is newly designed to prevent liquid accumulation. It is suitable for high boiling point substances. | Horizontal condensers are low in height and economical, but can efficiently recover vapors from low to high boiling point substances. | The Dewar flask condenser is suitable for recovering low boiling point substances by using ice or dry ice-acetone in the condenser. It has a unique structure that prevents the condensate from the condenser from flowing back into the sample flask through the capillary. |

| Specifications |  |

|

|

| Cooling area 0.146m2, Adapter, 1L sample flask (pear shaped) TS29/38, 1L receiving flask (round shaped) S35/20, Rotary joint (18 ID × total length 178mm TS29/38)

(BVF model is EYELA COAT® specification (condenser, adapter, receiving flask)) |

Cooling area 0.146m2, 1L sample flask (pear shaped) TS29/38, 1L receiving flask (round shaped) S35/20, Rotary joint (18 ID × total length 272mm TS29/38

|

110 OD x 340Hmm (91 ID x 230mm), Adapter, 1L sample flask (pear shaped) TS29/38, 1L receiving flask (round shaped) S35/20, Rotary joint (18 ID × total length 178mm TS29/38)

|

|

♦ Select the bath type

| Bath type | Without bath | Water bath | Water bath (Enhanced safety features) | Water・Oil bath |

| Bath type |

N-1210B∇△ | N-1210B∇△-W | N-1210B∇△-WS | N-1210B∇△-WB |

| The condenser model (V・S or T) is indicated by ∇, and “F” in △ denotes EYELA COAT® | ||||

| Configuration |  |

|

|

|

| Bath temperature control range (Control accuracy) | – | RT+5 to 90℃ (±1℃) |

RT+5 to 90℃ (±1℃) |

RT+5 to 180℃ (±1.5℃, oil: ±3℃) |

| Bath safety features | – | Fuse, Fixed temperature overheat protector, Insulated protective bath cover | Dry-heating protection unit (float switch), Fixed temperature overheat protector, Dedicated bath detector, Fuse, Insulated protective bath cover, Self-diagnostic function | Fuse, Fixed temperature overheat protector, Insulated protective bath cover |

| Bath material | – | Stainless steel | Stainless steel | Aluminum (Teflon® coating) |

| Bath internal dimensions | – | 220 ID x 120H (mm) | 220 ID x 120H (mm) | 240 ID x 120H (mm) |

| Bath capacity | – | Approx. 4.3L | Approx. 4.3L | Approx. 5.4L |

| Heating method | – | Heater: 1.05kW | Heater: 950W | Heater: 1kW |

| Rotation speed range | 5 to 280rpm | |||

| Evaporation capacity | Max. 23mL/min (water evaporation rate, JIS standard 1L flask) | |||

| Rotation setting・display | Speed control knob・rotation digital display | |||

| Jack function | Electric lift (100 mm) + manual slide (130 mm) | |||

| External input・output | Communication terminal for vacuum controller NVC-3000, communication terminal for low temperature circulator | |||

| Rotary motor | Stepper motor | |||

| Vacuum seal | Teflon® seal | |||

| Connection port diameter | Cooling water nozzle・suction nozzle 10mm OD | |||

| Ambient temperature range | 5 to 35℃ | |||

| Power input ・supply voltage | 2A, 200VA・100 to 230VAC 50/60Hz | 5.7A, 1.25kVA・220VAC 50/60Hz or 12.5A, 1.25kVA・115VAC 50/60Hz | 11.5A, 1.15kVA・100 to 115VAC | 5.5A, 1.2kVA・220VAC 50/60Hz or 12A, 1.2kVA・115VAC 50/60Hz |

◊ Performance values are based on room temperature of 20°C and rated power supply voltage.

◊ Evaporation capacity varies depending on conditions such as rotation speed, reduced pressure, bath temperature, condenser temperature, and sample flask.

▶▶▶ Introducing how to assemble an evaporator and important points to note (N-1300)

• List of all models including condenser (with or without EYELA COAT®), bath and jack

◊ All N-1210 models come with the high performance auto jack type drive unit.

◊ Models with “F” in the model number are EYELA COAT® specifications. EYELA COAT® is applied (N-1210BV model) to condensers, adapters, and receiving flasks while rotary joints and sample flasks are not coated.

| Condenser | EYELA-COAT® | Bath type | Outer dimensions (mm) | Model | Cat. No. |

V type  |

Without | Without | 510W x 359D x 800 (Highest position 1030)H | N-1210BV | – |

S Type  |

670W x 359D x 520 (Highest position 750)H | N-1210BS | – | ||

T Type  |

510W x 359D x 748 (Highest position 978)H | N-1210BT | – | ||

| V type | Water bath | 579W x 438D x 800 (Highest position 1030)H | N-1210BV-W | – | |

| S Type | 742W x 438D x 520 (Highest position 750)H | N-1210BS-W | – | ||

| T Type | 579W x 438D x 748 (Highest position 978)H | N-1210BT-W | – | ||

| V type | Water bath (Enhanced safety features) | 579W x 438D x 800 (Highest position 1030)H | N-1210BV-WS | – | |

| S Type | 742W x 433D x 520 (Highest position 750)H | N-1210BS-WS | – | ||

| T Type | 579W x 433D x 748 (Highest position 978)H | N-1210BT-WS | – | ||

| V type | Water・Oil bath | 566W x 433D x 800 (Highest position 1030)H | N-1210BV-WB | – | |

| S Type | 729W x 433D x 520 (Highest position 750)H | N-1210BS-WB | – | ||

| T Type | 566W x 433D x 748 (Highest position 978)H | N-1210BT-WB | – | ||

| V type | With

EYELA COAT® |

Without | 510W x 359D x 800 (Highest position 1030)H | N-1210BVF | – |

| V type | Water bath | 579W x 438D x 800 (Highest position 1030)H | N-1210BVF-W | – | |

| V type | Water bath (Enhanced safety features) | 579W x 438D x 800 (Highest position 1030)H | N-1210BVF-WS | – | |

| V type | Water・Oil bath | 566W x 433D x 800 (Highest position 1030)H | N-1210BVF-WB | – |

• Data

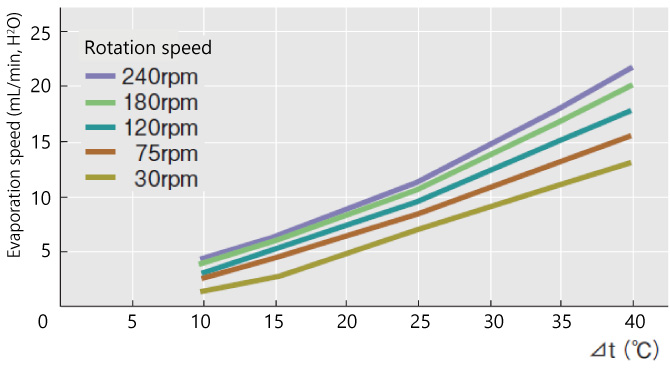

♦ Evaporation capacity curve

⊿t : Difference between bath temperature and boiling point of sample (water)

Conditions: Cooling water temperature set at 0°C, room temperature of 20 to 21°C, JIS sample flask of 1L (filled with 500mL).

Evaporation volume is calculated based on the time from the start of evaporation until it disappears.

• Options

♦ Anti-condensation cover to reduce condensation on condensers and nozzles

Configuration: Condenser cover, Nozzle cover (2 pcs)

Materials: PP, Thermal insulation material・Urethane foam

Operation: Circulating fluid temperature -10℃ or above (when circulating cooling medium)

By attaching the anti-condensation cover to the condenser and nozzle of the rotary evaporator, the occurrence of condensation can be reduced. This cover can be installed not only on new products, but also on conventional products that we have released so far.

| Product name | Anti-condensation cover for type V condenser | Anti-condensation cover for type S condenser |

| Cat. No. | 270740 | 270730 |

♦ Anti-condensation cover (transparent)

Configuration: Condenser cover, Nozzle cover (2 pcs)

Materials: Transparent PET, Silicone, Foamed silicone

Operation: Circulating fluid temperature 5℃ or above

| Product name | Anti-condensation (transparent) cover for type V・S condenser |

| Cat. No. | 266110 |

▶▶▶ The effectiveness of anti-condensation covers

• Parts

• Genuine glass vessels and other parts

♦ Standard parts

Rotary joints, Sample flasks (pear shaped), Receiving flasks, Trap balls, Separable flasks, Test tubes・Glass reducing adapters, Condensers・Adapters, vacuum seals・Teflon® seals, Vacuum hoses・Cooling hoses, Capillaries, Bumping prevention device, etc.

♦ EYELA COAT® shatterproof coating for glass vessel breakage

Condensers, receiving flasks, and adapters are provided as standard items, while sample flasks, trap balls, etc. are available as options. The coating is an environmentally friendly polyurethane that is less likely to break and has a new composition that prevents glass and samples from scattering in the unlikely event of breakage. This composition has excellent chemical properties and is so transparent that the coating is virtually invisible.