• Freeze dryer capable of integrating a vacuum pump within the main unit

• Model FDL-1000 and FDL-2000

• Example of system configuration

♦ FDL-1000 features a trap temperature of -45°C, while FDL-2000 achieves a trap temperature of -80°C. Both models offer a dehumidifying capacities of 4L and 3L per batch, respectively. Depending on the sample vessels, optional manifolds and drying chambers can be freely interchanged to configure a freeze-drying system. These modular freeze dryers can also accommodate an optional vacuum pump within the main unit.

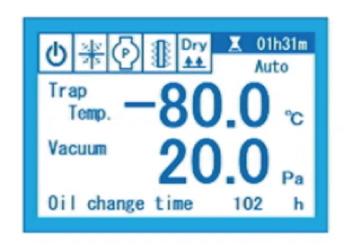

• Bright, easy-to-read 3.4-inch LCD display

Equipped with an LCD screen, the system clearly displays not only the trap temperature and vacuum level, but also the overall operational status at a glance.

• Simple operation

In Auto Mode operation, the system monitors the trap cooling temperature and vacuum level to notify when the sample vessel can be attached. After starting, operation is simplified to attaching the flask and stopping the process once drying is complete (when using the manifold).

• Trap monitor

The optional trap monitoring system can be installed. The monitoring lamp allows you to check the trap status before reaching the maximum dehumidification capacity.

• Built-in timer function

The display of the vacuum pump’s cumulative operating time and freeze-drying time helps determine the appropriate time for oil replacement in the vacuum pump and is useful for measuring sublimation time.

• Contamination prevention and nitrogen purge available

A 0.2 μm filter is installed at the air inlet to prevent contamination in the event of a vacuum release. Nitrogen purging is also available to prevent sample oxidation.

• Countermeasures against power failure

In the event of a power failure, the vacuum pump will not automatically resume operation. This feature helps prevent splashing caused by bumping of samples thawed due to the power interruption (the power recovery time can be adjusted).

• Recorder output terminal

For drying data management, the unit is equipped with standard recording output terminals for vacuum pressure and trap temperature. A dedicated recorder connection cord is available as an option.

• Improved maintainability with pump slide base

The vacuum pump installation area features a sliding design, making oil changes and maintenance easier. Thanks to the notched slide base, oil can be drained easily during oil changes, and there is no concern about oil dripping onto the pump’s slide base plate.

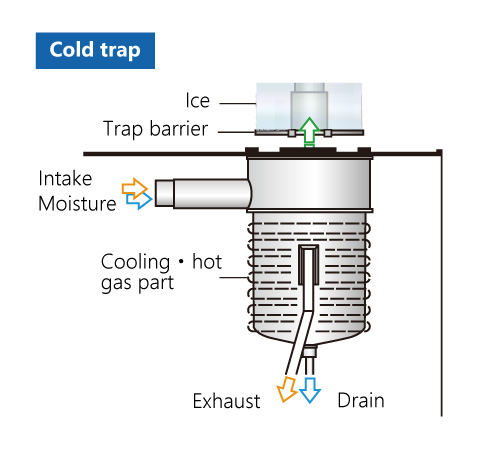

• Vacuum pump-friendly construction

The drain and exhaust piping are separated, so moisture will not be sucked directly into the vacuum pump even when power is restored. The defrost (hot gas) operation allows the trap barrier to remove ice that has formed on the trap.

• Fixing clamp for improved earthquake resistance

• Specifications

| Product name | Freeze Dryer | |

| Model | FDL-1000 | FDL-2000 |

| Cat. No. | 280918 | 280928 |

| Cooling method | Cold trap chamber cooling | |

| Cold trap temperature | -45℃ | -80℃ |

| Dehumidifying volume | 4L/batch | 3L/batch |

| Setting・display | Membrane keypad・LCD display | |

| Trap thermometer | T thermocouple | |

| Vacuum gauge | Pirani vacuum gauge (digital display) 0.0 to 533 Pa | |

| Safety features | Earth leakage/overcurrent breaker, Refrigerator overload relay, Refrigerator high-pressure switch, Automatic vacuum release, Oil change alarm, Fuse for built-in outlet, Control board self-diagnostic function |

|

| Vacuum release function | Automatic vacuum release valve | |

| Trap defrosting function | Defrosting by hot gas | |

| Additional function | Vacuum pump control, Ready to freeze drying indication, Vacuum pump running time indication, Stopwatch function, Select action after power failure, Abnormal vacuum rate monitoring (constant value), Refrigerator protection timer, Trap amount monitor (optional) | |

| Recorder output | Trap temperature: 1℃/1mV, Vacuum: 1Pa/1mV | |

| Vacuum pump required | 100/120L/min (50/60Hz) or higher (option) | |

| Number of ports | Depends on option selection | |

| Refrigerator・refrigerant | Air-cooled, output 600W・R404A | Air-cooled, output 500W x 2・R404A / R23 |

| Cold trap dimensions (mm) | 200 ID x 300H | |

| Cold trap material | Stainless steel | |

| Suction port diameter | 22 OD (mm) | |

| Built-in outlet | Max. 3A for dry chamber | |

| Ambient temperature range | 5 to 35℃ | |

| Outer dimensions (mm) | 700W x 550D x 955H | |

| Weight | Approx. 116㎏ | Approx. 144kg |

| Power input | 7.7A 1.7kVA | 11A 2.4kVA |

| Power voltage | 220VAC 50/60Hz | 220VAC 50/60Hz |

| Electrical requirement | 220VAC 10A | 220VAC Single phase 15A |

◊ Performance is measured at an ambient temperature of 20°C, no load, rated power supply voltage, 50 Hz.

◊ The amount of cooling gas contained is indicated on the serial number plate of the main unit.

◊ When connecting to a recorder, the dedicated recorder connection cord (optional) is required.

◊ The power input does not include the capacity of the built-in outlet.

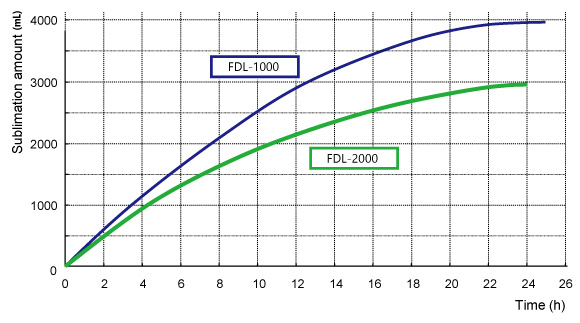

• Data

• Sublimation rate (FDL-1000・2000)

♦ Conditions

◊ FDL-1000

Ambient temperature : 20℃

Power supply : 220VAC 50Hz

Sample : 4L water

Sample vessel : 1L pear shaped flask

※ Pre-freeze 500mL of water in a 1L pear shaped flask (x 8 pcs). The amount of sublimation is calculated based on the remaining amount in the flask after the time has elapsed.

◊ FDL-2000

Ambient temperature : 20℃

Power supply : 220VAC 50Hz

Sample : 3L water

Sample vessel : 1L pear shaped flask

※ Pre-freeze 375mL of water in a 1L pear shaped flask (x 8 pcs). The amount of sublimation is calculated based on the remaining amount in the flask after the time has elapsed.

• Options

• Manifolds

| Product name | Valve size | Number of ports | Model | Cat. No. |

|

Flask manifold (conventional) ◊ If vessels other than TS29/38 are used, separate adapters are required. |

||||

|

TS29/38 | 4 | PMH-4A | 209560 |

|

TS29/38 | 4 | PMH-4 | 119820 |

|

TS29/38 | 8 | PMH-8 | 119830 |

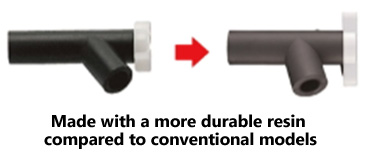

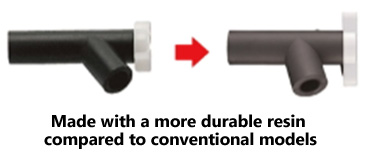

| Flask manifold (high durability, autoclave-compatible)

◊ If vessels other than TS29/38 are used, separate adapters are required. |

||||

|

TS29/38 | 4 | PMH-4AB | 276060 |

| TS29/38 | 4 | PMH-4B | 276050 | |

| TS29/38 | 8 | PMH-8B | 276070 | |

| Round manifold for flask

◊ PMH-1000B is highly durable and autoclavable. ◊ If vessels other than TS29/38 are used, separate adapters are required. |

||||

|

TS29/38 | 9 | PMH-1000 | 197440 |

|

TS29/38 | 9 | PMH-1000B | 276100 |

| Test tube・ampoule manifold (conventional)

◊ Adapters for test tubes and ampoules are separately required. |

||||

|

TS29/38 | 12 | PMH-12 | 119840 |

|

TS29/38 | 24 | PMH-24 | 119860 |

| Test tube・ampoule manifold (high durability, autoclave-compatible)

◊ Adapters for test tubes and ampoules are separately required. |

||||

|

TS29/38 | 12 | PMH-12B | 276080 |

|

TS29/38 | 24 | PMH-24B | 276090 |

• Drying chambers

| Product name | Shelf size (mm) | Number of shelves | Number of 10mL vials | Number of 66mm diameter Petri dishes |

Temperature control range | Model | Cat. No. |

| Drying chamber | |||||||

|

200W x 230D | 2 | 72 pcs x 2 | 8 pcs x 2 | RT + 5 to 40℃ | DRC-1N | 119730 |

|

220mm diameter | 1 | 58 pcs x 1 | 7 pcs x 1 | Fixed at 30℃ | DRC-2L | 119750 |

|

220mm diameter | 3 | 58+44+44 pcs | 7+5+5 pcs | DRC-3L | 119770 | |

| Sealing drying chamber | |||||||

|

220mm diameter | 1 | 58 pcs x 1 | 7 pcs x 1 | Fixed at 30℃ | BSC-2L | 119790 |

Sealing is only possible on the bottom shelf |

220mm diameter | 2 | 58+44 pcs | 7+5 pcs | BSC-3L | 119810 | |

• Stainless vats and holders for vials

These vats and holders significantly help to reduce setup time and enhance stability to prevent tipping.

| Picture | Product name | Model | Cat. No. |

|

Stainless vat for vials | VBS-1000 | 284250 |

| VBS-2000 | 284260 | ||

|

Stainless vat for vials + Holder | VBS-3000+VBH-3000 | 284300 |

| - | Stainless vat for vials | VBS-3000 | 284280 |

| - | Holder | VBH-3000 | 284290 |

• Related instruments

| Product name | Shelf board dimensions (mm) | Number of shelves | Number of vials | Sealing | Temperature control range | Model | Cat. No. |

| Drying chamber

|

240 x 240 | 3 | 10mL vial x 270 pcs

20mL vial x 168 pcs 30mL vial x 147 pcs |

Not available | -40 to 30℃ (shelf circulating fluid temperature) | DRC-1000 | 197450 |

| Manual handling | DRC-1100 | 197460 |

| Product name | Pre-freezing bath

|

Pre-freezer (flask rotator)

Designed for use in combination with PFR-1000

|

| Model | PFR-1000 | PFM-1000 |

| Cat. No. | 197410 | 197420 |

| Pre-freezing temperature | -45℃ | - |

| Compatible vessel | Sample flask (max. 2L), Freeze drying bottle max.1.2L | - |

| Vessels used in pre-freezer | - | Sample flask (TS29/38), Freeze drying bottle |

| Applicable model | - | PFR-1000, UT-3010・4000 |

| Rotation speed | - | 92/110rpm (fixed) |

| Product name | Displacement | Features | Model | Cat. No. |

| Dry vacuum pump (cannot be built into the main unit) | ||||

|

250L/min | Clean exhaust, oil-free, rated power supply: 0.34kVA, 100 to 240VAC | NeoDry15G-C | 282720 |

Vacuum hose adapter A: 22mm OD x 17mm OD |

- | 119240 | ||

| Vacuum pump (can be built into the main unit) | ||||

|

Displacement: 50 L/min / 60 L/min (50/60Hz) | Standard | GLD-051 | 190840 (100VAC)

190848 (220VAC) |

| Corrosion-resistant | GCD-051X | 190850 (100VAC)

190858 (220VAC) |

||

| Oil filter-equipped and corrosion-resistant | GCD-051XF | 191080 | ||

|

Displacement: 135 L/min / 162 L/min (50/60Hz) | Standard | GLD-137CN | 270580 (100VAC)

270588 (220VAC) |

| Corrosion-resistant | GCD-136XN | 189160 (100VAC)

189168 (220VAC) |

||

| Oil filter-equipped and corrosion-resistant | GCD-136XNF | 191090 | ||

Oil mist trap OMC-200 (for GCD-136XNF)

|

OMC-200 | 118690 | ||

Vacuum hose: 15mm ID x 36mm OD, Length 5m Vacuum hose: 15mm ID x 36mm OD, Length 5m |

- | 217910 | ||

Trap monitor for FDL model |

- | 197480 | ||

Recorder connection cord

|

- | 240170 | ||

Recorder |

μR-10000 | 219270 | ||