• Models LTE-510 and LTE-1010

• Precise programmable operation between -10°C and 60°C

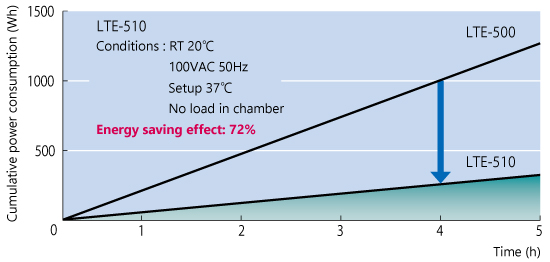

• Up to 72% reduction in power consumption

♦ Uses a low-power fan that suppresses heat generation. The control method changes according to the room temperature, reducing power consumption by up to 72% (compared to conventional models).

♦ Energy-saving operation (ECO mode) helps reduce both power consumption and CO₂ emissions.

♦ Compared to conventional models, LTE-510 reduces energy consumption by approximately 72%, and LTE-1010 by approximately 71%.

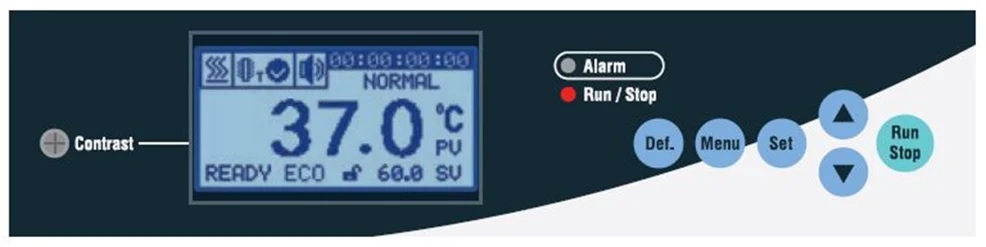

♦ Two types of control can be selected: ECO. mode for excellent energy-saving operation and CONT. mode for highly accurate temperature control precision.

• Two-tier stacking

Two LTE-510 units can be stacked using the optional two-tier stacking fixture.

• Program operation tailored to your needs

Equipped with a programmable temperature controller capable of temperature ramp control. The program supports up to 8-segment user-defined programs, including 1-step, 2-step, and 24-hour cycle programs.

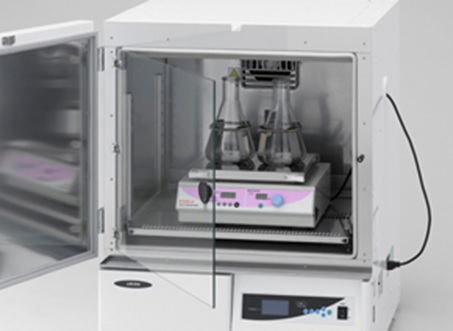

• Equipped with an inner door

A tempered glass inner door is provided as standard. This minimizes temperature fluctuations inside the chamber and allows observation of the inside of the chamber. By using a shelf for shaker (optional), a shaker can be placed inside the chamber for shaking culture.

♦ A cable port on the side of the unit allows for the installation of a shaker, temperature sensor, etc. inside the chamber.

• User-friendly display and control panel

• Drainage of condensation water

♦ Condensate is drained into a tank on the side of the unit. Useful when no drainage outlet is available near the installation site. The tank is removable.

• Specification

| Product | Low Temperature Incubator | |

| Model | LTE-510 | LTE-1010 |

| Cat. No. | 274408 | 274418 |

| Convection method | Forced convection system | |

| Temperature control range | -10 to 60°C | |

| Temperature control accuracy | ECO. mode:±1.5°C (with refrigerator ON-OFF control),土0.1 to 0.2°C (with heater control), CONT. mode: 士0.1 to 0.2°C | |

| Temperature distribution | Spatial temperature deviation 0.7°C or less, Temperature ramp 1.5°C or less (at 37°C) | Spatial temperature deviation 1.5°C or less, Temperature ramp 2.0°C or less (at 37°C) |

| Safety features | Earth leakage・overcurrent breaker, Variable independent overheat protector, Door switch, Refrigerator: High pressure switch, Overload relay (automatic recovery), Built-in outlet: Fuse, Condenser fan: Thermal fuse, Blower fan in chamber: Burnout prevention circuit, Temperature controller self-diagnostic function (upper and lower temperature limit alarm, heater・sensor disconnection, power failure, watch dog, refrigerator abnormal high pressure, overheat, door alarm, temperature ramp failure, heater SSR failure) | |

| Temperature control | ECO. mode: refrigerator ON-OFF, CONT. mode: heater PID control + refrigerator continuous operation | |

| Setting・display (temperature) | Membrane keypad digital setting・LCD digital display (min. 0.1°C) | |

| Defrosting | Automatic defrost (auto/timer), Manual defrost | |

| Timer | Auto-start, Auto-stop, Auto-start + Auto-stop | |

| Program functions | 1-step and 2-step programs, 24-hour cycle program, temperature ramp (up to 8 steps) | |

| Temperature sensor | Platinum resistance thermometer Pt100 ohms | |

| Heater | 550W | 700W |

| Refrigerator・refrigerant | Air-cooled, output 175W・R134a | Air-cooled, output 300W・R134a |

| Fluorescent lamp | Option | |

| Inner chamber dimensions (mm) | 600W x 500D x 500H | 600W x 500D x 1000H |

| Chamber capacity | 150L | 300L |

| Shelf board load capacity | Uniform load max. 15kg/shelf | |

| Shelf board material | PE coating | |

| Number of shelf boards included | 2 shelf boards | 4 shelf boards |

| Shelf pitch・number of steps | 30mm・11 steps | 30mm・27 steps |

| Max. unit number of stacking | Two-tier | - |

| Exterior | Bonded steel plate, melamine resin baked coating | |

| Interior | Stainless steel | |

| Cable hole | 1 location on the right side, 40mm ID | |

| Built-in outlet | 2 external ports, 100VAC Max. 4A | 2 external ports, 100VAC Max. 2A |

| Ambient temperature range | 5 to 35°C | |

| Power input・supply voltage | 4.6A, 1kVA・220VAC 50/60Hz | 5.5A, 1.2kVA・220VAC 50/60Hz |

| Outer dimensions (mm) | 700(808)W x 730(820)D×890H | 700(808)W x 730(820)D x 1550H |

| Weight | Approx. 92kg | Approx. 145kg |

| Accessories | Fixing bracket, Drainage tank, Drainage tank rack | |

♦ Performance values are based on room temperature of 20°C, rated power supply voltage, 50 Hz, and no load.

♦ Temperature control accuracy is based on automatic defrost (disabled) or setting at 25°C or higher.

♦ Power input does not include the capacity of the built-in outlet.

♦ Dimensions in parentheses ( ) include protrusions, including drain tank rack.

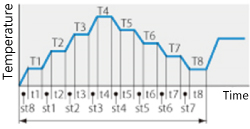

• Programs (operation patterns)

|

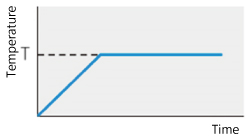

■ Fixed-temperature operation (NORMAL operation) Continuous operation at set temperature T. |

|

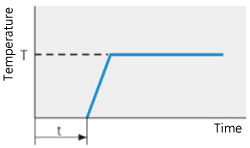

■ Auto-start operation Operation starts automatically at the set temperature T after the set time t elapses. Can be used in combination with other operation patterns. |

|

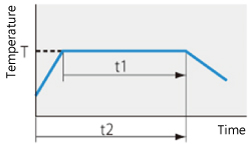

■ Auto-stop operation When the time is set and operation is started, it runs for the set time. After the time elapses, the control stops automatically. Timer setting can be selected between t1 and t2. |

|

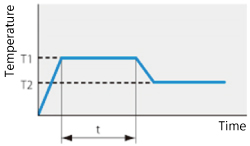

■ Operation in 1-step mode Two temperatures and one time are set. When the set time t elapses after reaching the set temperature T1, the temperature shifts to the set temperature T2 and fixed-temperature operation is performed. |

|

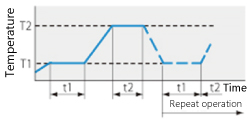

■ 2-step mode operation Set two temperatures and time, and set the number of times to repeat. After time t1 elapses at set temperature T1, temperature control is performed at set temperature T2 until time t2 elapses. This operation is repeated for the number of times, and temperature control is stopped. |

|

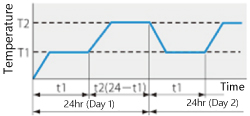

■ 24-hour operation The unit operates repeatedly for a set number of times in a 24-hour cycle, with 24 hours as one loop. After operation, operation is performed at the set temperature for fixed-temperature operation. |

|

■ Ramp program operation The set time T, set temperature t, ramp time st, and number of repetitions can be set for up to 8 sections. After the specified number of times, operation is executed at the set temperature for fixed-temperature operation. |

• Data

• Running cost comparison

| Comparison of CO2 emission and electricity cost | |||

| Model | CO2 Emission (kg/yr) |

Annual electricity cost | Energy saving |

| LTE-500 (Conventional model) | 962 kg/yr | ¥40,959 | Approx. 72% |

| LTE-510 (Current model) | 269 kg/yr | ¥11,431 | |

| Annul reduction | – 693 kg/yr | – ¥29,528 | |

| LTE-1000 (Conventional model) | 1,210 kg/yr | ¥51,489 | Approx. 71% |

| LTE-1010 (current model) | 346 kg/yr | ¥14,738 | |

| Annul reduction | – 864 kg/yr | – ¥36,751 | |

♦ Under the condition of continuous operation, 24 hours a day, 365 days a year.

♦ The CO₂ reduction amount is calculated using the emission factor of 0.457 (kg-CO₂/kWh) as published in the “2024 CO₂ Emission Factors” by the Ministry of the Environment (Tokyo Electric Power Energy Partner website).

♦ Electricity costs are calculated based on a rate of 19.45 yen/kWh (Tokyo Electric Power Energy Partner, commercial power contract for over 500 kW, including summer rates, year-round).

♦ The comparison is based on the equipment set at 37℃, with an ambient temperature of approximately 20°C, and a power supply of 100VAC/50Hz.

• Comparison of energy consumption

(Comparison between LTE-510 and the conventional LTE-500)

• Options

| Product | Specification | Model | Cat. No. |

Dedicated stand  |

Only for LTE-510 | HSS-41C | 100320 |

Two-tier stacking metal fixture  |

Only for LTE-510 | - | 274830 |

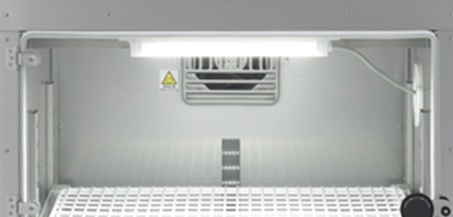

Interior light (LED bar)  |

Includes LED white fluorescent light for checking inside the chamber, mounting board, and ON-OFF switch. | - | 275590 |

| Fluorescent light unit | Day and night operation utilizing illumination can be performed for algae culture and plant growth.

Illuminance: Approx. 3,000Lx (measured at the center of the chamber, using four 10W fluorescent lamps) Program Function: 24-hour (2-step) digital control LTE model temperature setting range: 5 to 40°C Power Input: 2A, 200V Power Supply Voltage: 100VAC, 50/60Hz ※ When installed in the LTE-510 model, the effective internal chamber height will be 278mm. |

LU-1000 | 210430 |

Hatch clip with keyhole  |

Padlock is not included | - | 214250 |

Shelf board  |

PE coating (1 piece) | - | 214530 |

| Shelf board | Stainless steel (1 piece) | - | 241630 |

Shelf board support  |

1 pair | HSH-601 | 100390 |

Shelf board for shaker  |

The shaker MMS series can be used by placing it in the incubator. One unit of MMS-120H, 220H, 320, 420, or 520 can be installed in the incubator.

※The maximum shaking speed is 150rpm, the maximum load is 500mL x 4 flasks for Model 400, and the maximum load capacity is 5kg.In addition, it may not be used for other vessels such as flasks and test tubes, depending on the type and angle of the holder and the operating temperature. ※ When using a shaker with the LTE-510 model stacked in two- tier, there may be restrictions on the shaking speed. For details, please contact us separately. |

HSI-4 | 261340 |

| Cable hole plug | For LTE series | - | 111690 |