PPX-1000

• Automated and labor-saving organic synthesis experiments, high-performance temperature control

♦ The Single Master is a compact personal model that meets the requirements of next-generation synthesis methods in organic chemistry and process chemistry R&D in the field of fine chemicals (pharmaceuticals, new materials, electronics, and chemicals).

Stirrer model Impeller model

◊ The Single Master is equipped with a system that can automatically change the cooling and dosage rate so that the temperature inside the vessel can be controlled and does not deviate from the reaction temperature. If an exothermic reaction occurs, the cooling and dosage can be automatically stopped, so you can leave the experiment unattended or conduct the experiment overnight.

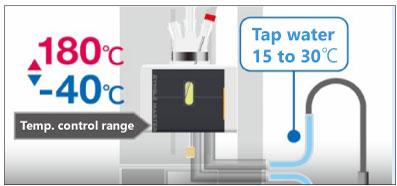

◊ The newly developed aluminum block thermostatic chamber with water-cooled heating and cooling mechanism can adjust the temperature from -40 to 180°C. Even with tap water supply, cooling experiments to -40°C are possible.

◊ The aluminum block thermostatic chambers are safe and clean to use, with no oil hazard or splashing.

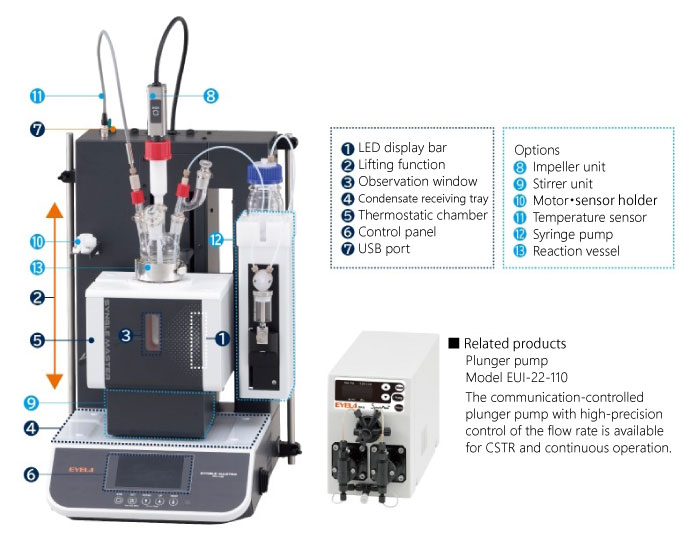

◊ The main unit allows for external temperature control (heating, cooling, isothermal, and ramp control) on its own. By combining it with optional components such as internal temperature control sensors, stirring devices (stirrers and impellers), syringe pumps for dosage control, and plunger pumps for continuous operation, a system can be configured to meet specific requirements.

◊ The reaction vessel is compatible with the ChemiStation PPV and can accommodate a synthesis scale of 150mL. The newly added vessel with an outflow nozzle allows for liquid extraction from the bottom of the reaction vessel. By connecting a Teflon® tube, continuous reactions (CSTR) can be achieved, enabling large-scale synthesis.

◊ With a wide range of options, we can meet various demands such as “stabilization of temperature control,” “enhancement of stirring power,” “reactions accompanied by intense heat generation,” “performing reactions at low temperatures,” “long-duration high-precision dispensing,” “rapid cooling and slow cooling,” and “the need for large-scale synthesis in a short time.”

▶▶▶ Introducing the Personal Organic Synthesizer, Single Master PPX-1000

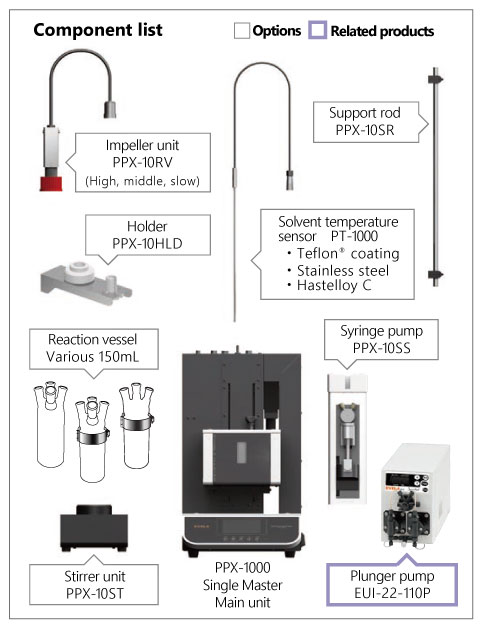

• Component diagram

• Name of each parts

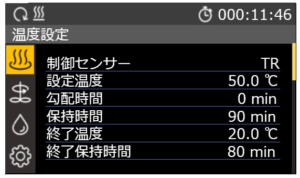

• Easy-to-read display

♦ Menu Screen

Equipped with the newly developed controller “eReact”. It allows for high-precision temperature control through simple settings and cascade control for essential parameters needed for condition evaluation (temperature, stirring, dosage).

◊ The display can be switched to English.

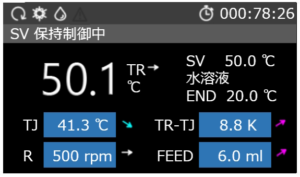

♦ Operation Screen

During operation, setting changes, stopping, modifying, and restarting reactions can be easily executed. Each parameter is monitored every second, allowing for a comprehensive overview of the system’s operating status.

♦ Data Report

With simple operation using the dedicated controller “eReact”, individual reaction parameters (temperature, stirring, dosage amount) can be operated with high precision, and it supports everything from temperature control to data logging, contributing to improving the research environment in the laboratory. It supports USB export and allows recorded data to be saved to an external memory.

• Capable of handling both batch and continuous operations

♦ It accommodates reaction conditions that were previously difficult to manage.

♦ The aluminum thermostatic chamber achieves a wide temperature control range (-40°C to 180°C) through a water-cooled Peltier system. By simply supplying water between 15°C and 30°C, cooling experiments down to -40°C, which were previously difficult, are now possible. Since water is used for heat exchange, it operates with a GWP value of zero, making it compliant with non-fluorocarbon and brine regulation requirements.

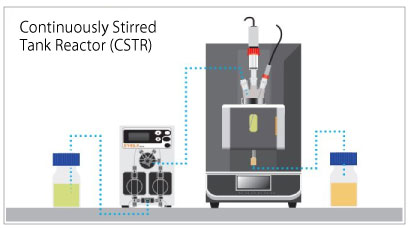

• Continuously Stirred Tank Reactor (CSTR)

♦ The system can be configured for both batch (discontinuous) and CSTR operations. By connecting multiple units and combining them with a reagent addition pump (optional), parallel or continuous reactions can be achieved. Depending on the experimental objectives, systems for temperature condition studies, dosage addition condition studies, two-stage continuous reactions, or scale-up synthesis can be configured. For CSTR, an elevation adjustment function of the aluminum thermostatic chamber is included to control the liquid level of the reaction solution.

• Internal Vessel Temperature Control (optional)

♦ The aluminum block thermostatic chamber is equipped with heating and cooling PID control, featuring a safety system that allows for adjustable cooling speed. By using an internal temperature sensor (optional), temperature settings can be configured for the reaction temperature (ramp + heat retention, time) and the final temperature (heat retention, time).

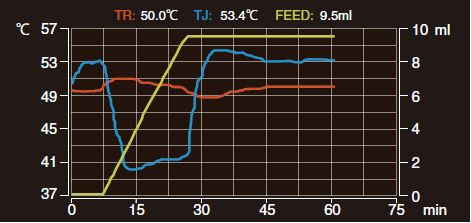

For internal temperature control, it is equipped with the same cascade control system as production equipment, allowing precise control of reaction temperature (internal temperature, external temperature, isothermal, ramp) and reaction time. Additionally, when combined with a syringe pump, it enables automated reagent addition. Heat from the reaction is safely dissipated within the set temperature range, ensuring safe reagent addition.

◊ TR: internal temperature (temperature of reaction solution), TJ: external temperature (temperature of aluminum block), FEED (dosage volume): volume already dispensed by syringe pump

• Reaction Vessel Common to the PPV Series

♦ The reaction vessel is compatible with the ChemStation PPV model and can accommodate a 150mL reaction vessel with an outer diameter of 60mm. This allows for reaction condition testing using small samples of 10–50 mL and multiple vessels.

♦ The reaction vessel with an outflow nozzle has also been added, allowing liquid to be extracted from the bottom of the reaction vessel. By connecting a Teflon® tube, CSTR is possible, allowing large-scale synthesis.

• Specifications

Please select the appropriate optional accessories, such as the internal liquid temperature control sensor, stirring unit (stirrers or impellers), syringe pumps for dosage control, and plunger pumps for continuous processes, to build a system tailored to your specific needs.

| Product name | Personal Organic Synthesizer : Single Master |

| Model | PPX-1000 |

| Cat. No. | 283040 |

| Reaction method | Batch type and flow type (CSTR) are available by selecting options |

| Stirring method | Stirrer (sold separately), Impeller (sold separately) |

| Number of reaction vessel | 1 pc |

| Synthesis scale | Max. 150mL (reaction vessel and glass parts are sold separately) |

| Temperature control range | -40.0°C to 180.0°C (thermostatic chamber). It requires connection to low temperature circulator, such as our CCA model or another suitable chiller |

| Temperature control accuracy | ±0.1°C (thermostatic chamber temperature value) |

| Rotation speed range

Stirrer unit (sold separately) |

High: 0, 125 to 1000rpm, max. shaft torque 19.6mN・m Middle: 0, 32 to 250rpm, max. shaft torque 68.6mN・m Low: 0, 8 to 63rpm, max. shaft torque 196mN・m |

| Rotation speed range

Impeller unit (sold separately) |

0, 100 to 2000rpm |

| Setting・display | Membrane keypad input・color TFT LCD display (4.3″), LED display bar (color display) |

| Temperature resolution | 0.1℃ |

| Temperature control | Heating and cooling PID control, Selectable internal vessel temperature control (optional liquid temperature sensor required), External temperature control, Fixed value control, Ramp control |

| Dosage control | Syringe pump unit PPX-10SS (sold separately): Total dosage volume (mL), Dosage time (min), Dosage temperature range (°C), Auto/Manual |

| Continuous addition control | Plunger pump EUI-22-110P (sold separately): Constant flow (0 to 9.99 mL/min) |

| Additional function | End temperature setting, PID constant change, Motor selection, Pump selection, Japanese/English (switchable display) |

| Chamber elevation function | Manual vertical slide (stroke 114mm, with lock mechanism) |

| Data record・report | Recorded data is output in csv format from USB Type-a connector to USB memory (sold separately), Format: FAT32 |

| Observation window | With observation window |

| Liquid temperature measurement | Liquid temperature sensor PT-1000S・H・T (sold separately) |

| Safety features | Reaction part drips receiving structure, Earth leakage breaker, Overcurrent protection (fuse), Lightning surge protection, Motor overload protection, Upper and lower temperature limiter settings, Temperature sensor disconnection detection, Thermostatic chamber temperature sensor error detection, Fixed temperature overheat protector (thermostatic chamber 195°C・water-cooled Peltier element 45°C) |

| Heating・cooling method | Heater 200W ・ Water-cooled Peltier element Max.250W |

| Temperature sensor | Platinum resistance thermometer Pt1000Ω |

| Temperature control・stirring unit | Temperature control unit included・stirring is optional |

| Reaction vessels | ChemStation PPV 150mL vessel with 60mm OD (sold separately) |

| Wetted part material | Glass, PTFE, PEEK, FFKM (depending on vessel type) |

| Cooling water connection diameter | 10.5mm OD hose port |

| Ambient temperature range | 5 to 35℃ |

| Power input | 8A, 800VA |

| Supply voltage | 100 to 240VAC 50/60Hz |

| Outer dimensions (mm) | 301(315)W x 444(511)D x 518(526)H |

| Weight | Approx. 23kg |

• Options

♦ Optional parts・related products

| Product name | Specifications | Model | Cat. No. |

| Inner vessel temperature sensor (Pt1000Ω) |

Stainless steel

3.2mm diameter |

PT-1000S | 283050 |

| Hastelloy C

3.2mm diameter |

PT-1000H | 283060 | |

| Teflon® coating

2.9mm diameter tip mold |

PT-1000T | 283070 | |

| Impeller unit | Rotation 0,125 to 1000rpm Max. shaft torque 19.6mN・m |

PPX-10RV-H | 283080 |

| Rotation 0, 132 to 250rpm

Max. shaft torque 68.6mN・m |

PPX-10RV-M | 283090 | |

| Rotation 0, 8 to 63rpm

Max. shaft torque 196mN・m |

PPX-10RV-L | 283100 | |

| Stirrer unit | 0, 100 to 2000rpm | PPX-10ST | 283110 |

| Flat plate baffle | PTFE 4 pcs for vessel | – | – |

| Syringe pump | Material: PTFE | PPX-10SS | 283120 |

| Plunger pump | Flow range 0.001 to 9.999mL/min | EUI-22-110P | 278550 |

| Motor & sensor holder | For motor, temperature sensor | PPX-10HLD | 283130 |

| Support rod | Common for left and right side, 1 piece | PPX-10SR | 283140 |

| Pressure reducing valve for tap water | Fixed pressure, 0.05 to 0.06MPa | – | 283810 |

| Vessel | With outflow nozzle, connection 1/4-28UNF | – | 283150 |

| Communication cable | For controlling plunger pump EUI-22-110P | PPX-EUI | 284100 |

◊ Reaction vessels compatible with the Chemistation PPV, with 60mm OD and a capacity of 150mL, can be used for the glass components.