• Model NRP-1000

• Compact model ideal for low flow rate applications

• Equipped with a rotation speed display for precise and quantitative operation

♦ Since only the tubing comes into contact with the liquid, there is no contact with metal parts, eliminating concerns about contamination.

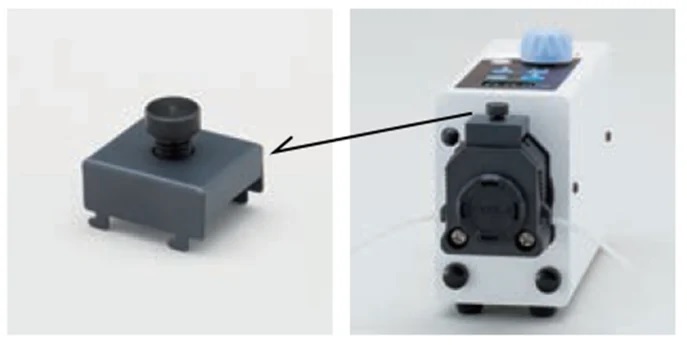

Its integrated tubing case design enables easy tube replacement by simply lifting the tubing holder.

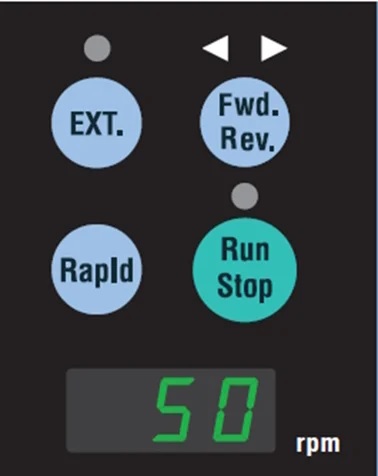

♦ The rapid-priming switch enables operation at the maximum flow rate, quickly filling the tubing path up to just before the dispensing point.

♦ Four types of tubing are available depending on the liquid being used: Silicone, PharMed®, Tygon®, and Versilon (Fulran®). Each type comes in three different inner diameters. Select the appropriate tubing based on the liquid type and required flow rate.

• Characteristics

• Clear display and excellent operability

The rotation speed is displayed digitally, allowing for precise and consistent setting of operating conditions.

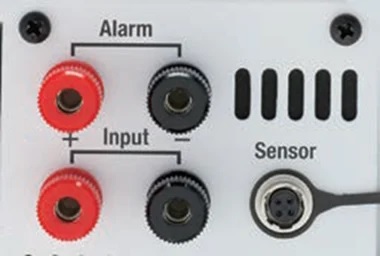

• Discharge volume can be adjusted via external signal input

Equipped with an external signal input terminal for discharge volume control via electric signals (0 to 10VDC) from a PC or measurement device. This enables automation of reagent addition and other delivery systems.

Equipped with an external signal input terminal for discharge volume control via electric signals (0 to 10VDC) from a PC or measurement device. This enables automation of reagent addition and other delivery systems.

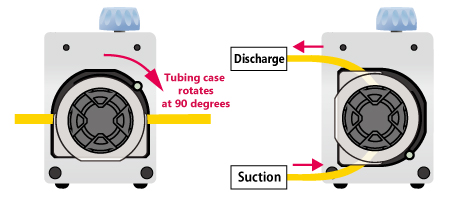

• Each tubing case can be individually fixed at 90° increments

Aligning the suction and discharge ports in the same direction allows for optimal tubing length without unnecessary bends or kinks. (Different tubing sizes can be combined for each channel.)

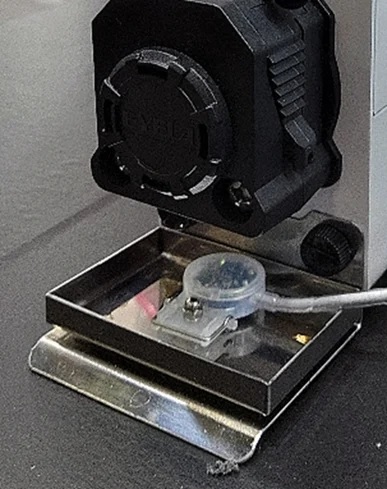

• Leak detection using the optional leak sensor

If a tube ruptures inside the tubing case, causing leakage, the optional leak sensor set detects the leakage and stops the liquid delivery. Made of Teflon®, the leak sensor provides excellent chemical resistance.

| Product | Leak sensor set |

| Cat. No. | 282820 |

| Set contents | Leak sensor (0.5m), Vat and Vat holder |

• Specification

| Product | Peristaltic pumps (Roller pumps) |

| Model | NRP-1000 |

| Cat.No. | 282748 (220V), 282749 (115V) |

| Number of tubes | 1 pc / 1 stage |

| Tubing case | 1 pc (made of PPS resin) |

| Flow rate range | 9 to 160mL/h (1.15 ID x 3.2mm OD tubing) 30 to 500mL/h (2.15 ID x 4.2mm OD tubing) 60 to 900mL/h (3.15 ID x 5.2MM OD tubing) |

| Flow rate accuracy | Within ±2% (repeatability within ±1%) |

| Discharge pressure | Max.196kPa (2.0kg/cm2) |

| Fluid viscosity |

Max. 2Pa・s (2000cP) |

| Temperature | -10 to 100℃ (no freezing) |

| Rotation speed | 1 to 40rpm |

| Rotation control | Open loop control |

| Rotation speed setting | Encoder-based digital setting |

| Rotation speed display | Digital display |

| Rapid-priming function | Included |

| Dispensing direction | Forward/reverse switchable (LED display) |

| Other functions | One-touch tubing replacement, Adjustable tubing case angle, Rapid-priming function |

| External output | Alarm output terminal (voltage free contact) |

| External input | External signal input terminal (0 to 5 VDC, 0 to 10 VDC selectable), Sensor signal input terminal (leak sensor: optional) |

| Safety features (option) | A leak sensor set (optional) detects leaks that occur when a tube breaks in the tubing case, etc., and stops the pumping of liquid |

| Motor | Stepper motor |

| Usable tubing material | Silicone, Tygon®, Versilon (Fluran®), PharMed® |

| Usable tubing diameter | 1.15 ID x 3.2mm OD, 2.15 ID x 4.2mm OD, 3.15 x 5.2mm OD |

| Ambient temperature range | 5 to 35°C |

| Power input・supply voltage | 0.07A, 16VA・220VAC 50/60Hz, 0.09A, 10VA・115VAC 50/60Hz |

| Outer dimensions (mm)・weight | 73W x 226(241)D x 121(139)H・2.1kg |

♦Performance values are based on room temperature 20°C, rated power supply voltage, 50 Hz, water, liquid temperature 21°C, back pressure 0, and use of specified silicone tubing.

♦Tubing is sold separately. Flow rate, discharge pressure, and other performance parameters may vary depending on the tubing selected.

♦Discharge volume may decrease if the liquid viscosity exceeds 0.1Pa·s (100cP).

♦The operating temperature for Tygon® tubing is 0 to 70°C.

♦Dimensions in parentheses ( ) include protrusions.

• Options

• Tubing available

Select tubing materials and diameters based on your application requirements.

• Leak sensor set

If a tube ruptures inside the tubing case, causing leakage, the optional leak sensor set detects the leakage and stops the liquid delivery. The leak sensor is made of Teflon® for high chemical resistance.

| Product | Leak sensor set |

| Cat. No. | 282820 |

| Set contents | Leak sensor (0.5m), Vat and Vat holder |

• External signal input・alarm output cable

| Product | External signal input・alarm output cable |

| Cat. No. | 283590 |

| Standard | The cable is shared for both external signal input and alarm output. (Cable length: 3m) |

• Tubing case set

| Product | Tubing case set |

| Cat. No. | 282770 |

• Adjuster

| Product | Adjuster |

| Cat. No. | 282830 |

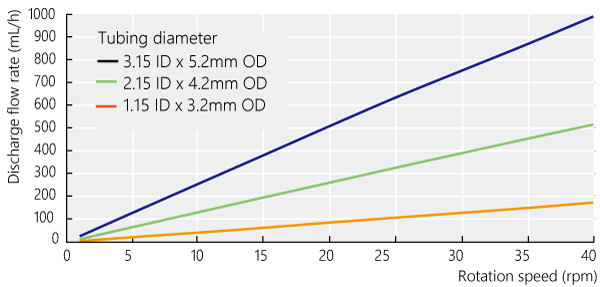

• Data

• Flow rate characteristics

Conditions:

Tubing: Silicone tubing

Liquid: Deionized water

Liquid temperature: 20°C

Ambient temperature: 20°C

Back pressure: 0

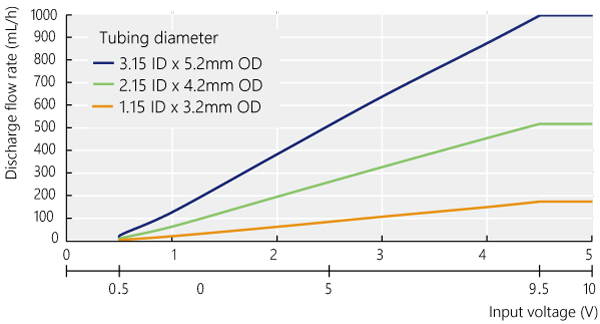

• Flow rate characteristics based on reference voltage input

Conditions:

Tubing: Silicone tubing

Liquid: Deionized water

Liquid temperature: 20°C

Ambient temperature: 20°C

Back pressure: 0