• A simple column-type flow reactor, ideal as an entry-level model for continuous flow synthesis

MCR-1000 MCR-1000 |

♦ With a simple configuration consisting only of a column and heating reactor, flow synthesis can be easily initiated using your existing liquid dispensing pump. This system serves as an ideal introduction to flow synthesis techniques. Equipped with refillable cartridge-type columns, MCR-1000 is also well suited for catalyst screening applications.

♦ The aluminum block heating reactor provides highly precise temperature control within a range of 50 to 200°C.

• Low-cost columns

♦ Columns are available in six variations—3, 5, and 10 mm inner diameters with lengths of 50 or 100 mm—and are made of either stainless steel or glass. Glass columns are suitable for acid-involved reactions.

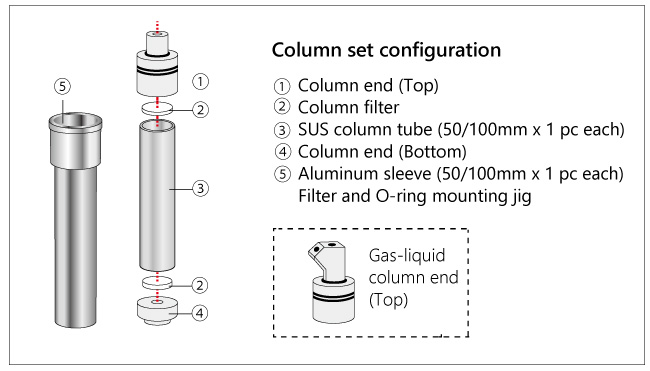

♦ The columns consist of disposable stainless steel or glass tubes combined with column filters. This design reduces column costs to roughly one-tenth of those of conventional products. It also significantly simplifies column cleaning and catalyst replacement.

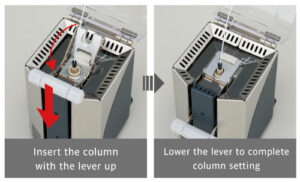

• Simple operation

♦ A toggle clamp mechanism securely attaches the column to the heating reactor. Mounting is quick and easy—just operate the lever (PAT).

♦ Two column connection types are available: a basic single-liquid flow path and a gas-liquid dual-tube connection. Liquid-liquid and gas-liquid reactions can be performed by replacing the single-liquid column end (included in the column set) with an optional gas-liquid column end. The gas-liquid column end is particularly effective for catalytic gas-liquid reactions, such as hydrogenation.

• Specifications

| Product name | |

| Model | MCR-1000 |

| Cat. No. | 267950 |

| Reaction method | Flow method(by liquid dispensing pump) |

| Reaction vessel | Stainless steel・glass tube (option) |

| Columns | 3・5・10mm ID x 50・100mm length |

| Column mounting | By lever up/down (toggle clamp mechanism) |

| Max. pressure | Less than 1MPa |

| Temperature control range | 50 to 200°C (aluminum block temperature) |

| Control accuracy | +1.0°C or less (aluminum block temperature) |

| Temperature control | Aluminum block jacket control, heating PID control |

| Temperature setting/display | Membrane keypad input・digital display |

| Sample inlet | One-liquid flow path/Gas-liquid dual tube connection (option) |

| Safety features | Temperature controller self-diagnostic function (variable upper temperature limit/sensor error), Independent overheat protector (thermal fuse), Earth leakage/Overcurrent breaker |

| Wetted part material | PTFE・PEEK・FFKM・SUS316・Glass |

| Connection tube・ Thread standards |

1/16″ OD tube・No.10-32UNF |

| Ambient operating temperature | 5 to 35°C |

| Power input | 2.0A, 200VA |

| Supply voltage | 100VAC 50/60Hz |

| Weight | Main unit: 2.9kg, Control unit:1.8kg |

| External dimensions(mm) | Main unit: 124W x 163D x 214H,

Control unit: 80W x 220D x 151H |

◊ The column set is sold separately.

• Options

• Column set

| Product name | Standard | Cat. No. |

| Column set (3mm diameter) | — | 268780 |

| Column set (5mm diameter) | — | 268790 |

| Column set (10mm diameter) | — | 278800 |

| Column end (3mm diameter) | For gas-liquid | 268200 |

| Column end (5mm diameter) | For gas-liquid | 268210 |

| Column end (10mm diameter) | For gas-liquid | 278810 |

• Tube reactor MCR-PFR

This is a tube reactor for liquid phase reactions such as homogeneous catalysts. It is possible to wrap a PTFE tubing (sold separately) with 1/16 inch OD up to about 3m around the tube reactor and mount it to the MCR-1000 main unit.

• PTFE tubing

- 0.5mm ID x 1/16″: Approx. 0.6mL

- 0.8mm ID x 1/16″: Approx. 1.5mL

- 1.0mm ID x 1/16″: Approx. 2.4mL

Note: These values are theoretical estimates based on a 3-meter tube length.

| Product name | Standard | Model | Cat. No. |

| Tube Reactor ※Please purchase tubes separately. |

— | MCR-PFR | 276140 |

| PTFE tubing (10m) | 0.5mm ID x 1/16″ | — | 276150 |

| 0.8mm ID x 1/16″ | — | 276160 | |

| 1.0mm ID x 1/16″ | — | 276170 |

• Tubing

| Product name | Standard (mm) | Cat. No. |

| Stainless steel tubing (10 pcs) | 3 diameter x 50 | 268020 |

| 5 diameter x 50 | 268030 | |

| 10 diameter x 50 | 278830 | |

| Stainless steel tubing (10 pcs) | 3 diameter x 100 | 267990 |

| 5 diameter x 100 | 268000 | |

| 10 diameter x 100 | 278820 | |

| Glass tubing (10 pcs) | 3 diameter x 50 | 268080 |

| 5 diameter x 50 | 268090 | |

| 10 diameter x 50 | 268100 | |

| 3 diameter x 100 | 268050 | |

| 5 diameter x 100 | 268060 | |

| 10 diameter x 100 | 268070 | |

| Column filter (100 pcs) | 3 diameter | 268110 |

| 5 diameter | 268120 | |

| 10 diameter | 278840 |

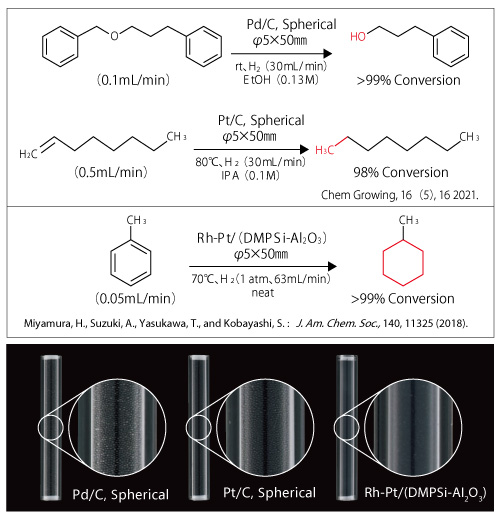

• Immobilized catalyst cartridges

This is a column tube filled with a catalyst for flow reactions with low pressure loss and high activity. It can be used by mounting it to the heating reactor immediately after opening. The column size is 5mm ID x 50mm in length, and the column material is glass. Three types of catalyst are available.

<Catalyst supply: Fujifilm Wako Pure Chemical Corporation>

◊ Storage conditions: 2 to 10°C

| Product name / QTY | Packing volume | Model | Cat. No. |

| Pd/C, spherical (5% palladium) / 3 pcs | 660 to 710mg/pc | Pd/C | 281030 |

| Pt/C, spherical (5% platinum) / 3 pcs | 660 to 710mg/pc | Pt/C | 281040 |

| Rh-Pt/(DMPSi-Al2O3) (Rhodium-Platinum) / 3 pcs | 830 to 880mg/pc | Rh-Pt/DMPSi-Al2O3 | 281050 |

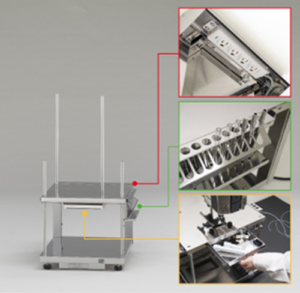

• SynpleFlow stand

The stand is equipped with a 4-built-in outlet (power capacity: 8A) for easy power management. The pull-out drawer on the front of the stand allows for convenient storage of column parts and small components. The column rack, attachable to either side of the stand, enables efficient and organized experimentation.

Model: STT-1010

Cat. No. 276310

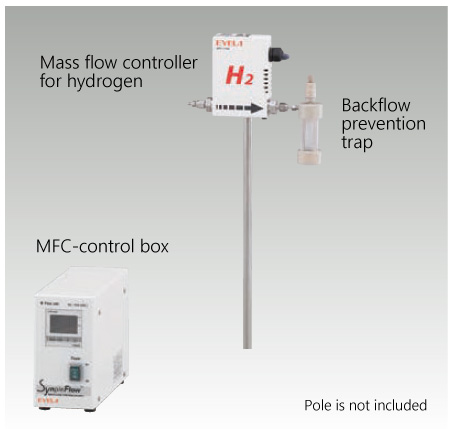

• SynpleFlow gas addition unit

This is a gas addition unit for hydrogenation reactions. It supplies hydrogen gas into the column at any flow rate. The wide operating differential pressure range allows for stable gas flow control even during pressure fluctuations. No need to adjust the gas source supply pressure each time.

It comes standard with the backflow prevention mechanism and the trap for reaction liquid, and prevents damage to the mass flow controller due to liquid contamination. In addition, for applications that do not use reaction liquid, you can also select a type without a backflow prevention trap (MFC-1100-H2). Equipped with 0 to 5VDC analog output terminal. By connecting to a data logger or recorder, it is possible to record and manage measured flow data during the reaction. Note that recorder output cable is sold separately.

Product Name: SinpleFlow gas addition unit

Flow control range: 2 to 100mL/min

Maximum working pressure: less than 1.0MPa

Model: MFC-11GU

Cat. No.: 276320

◊ Please inquire about changing gas type and flow rate.

Product name: Recorder output cable for LCR and MCR

Cat. No.: 276280

Product name: Alarm input/output cable for LCR and MCR

Cat. No.: 276290

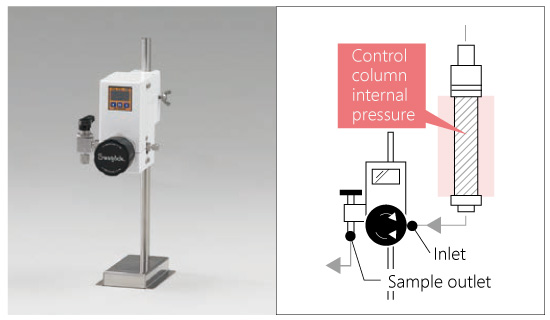

• Pressure regulating valve unit

The column internal pressure can be controlled at any desired value by operating the valve. The valve unit can be removed from the stand and installed anywhere you like, such as on an angle or a stand pole. It is equipped with a recorder output terminal, so measured values can be output and recorded. Note that the output cord is sold separately.

Product Name:Pressure regulating valve A Pressure adjustment range: 0 to 1.5MPa

Pressure value display: 0 to 3.5MPa, digital display

Model: BPR-1000A

Cat. No.: 274450

Inlet: Right side

Product name: Pressure regulating valve B

Model: BPR-1000B

Cat. No.:No.274460

Inlet port: Left side

Product name: Torque, rotation, pressure signal output cord

Cord length 2.5m

Model: ZO-2000

Cat. No.: 120890

• Medium and high pressure liquid dispensing pump

EUI-22 features a linear-driven double-plunger mechanism, enabling stable liquid delivery with minimized pulsation.

Flow control range: 0.001 to 9.999mL/min

Discharge pressure: 20MPa (Model 110P), 35MPa (Model 110S)

Model: EUI-22-110P

Cat. No.: 278550

Wetted parts: PEEK

Model: EUI-22-110S

Cat. No.: 278560

Wetted part: Stainless steel