• Liquid samples are directly converted into fine powder.

• Spray drying is an ideal method for polymers, medicines, organic and inorganic compounds, and new materials.

♦ Instant drying enables short processing time. The sample is not subjected to high thermal stress.

♦ Since liquid samples are directly converted into fine powder, there is no need for pre-processing such as filtration and concentration or post-processing such as grinding.

♦ Since drying is possible even with a small amount of solid content in the gram order, experiments can be easily conducted at the laboratory level.

▶ Introduction to the drying process and conditions of the spray dryer SD-1010

• Main features of SD-1010

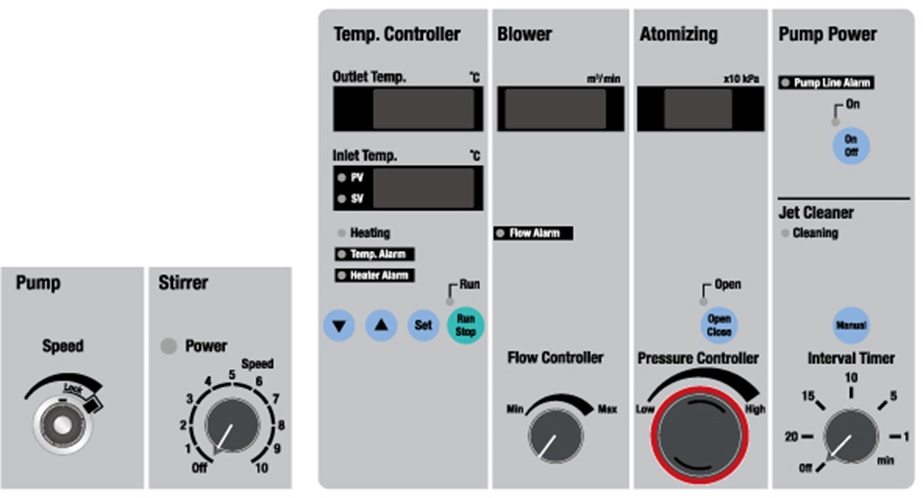

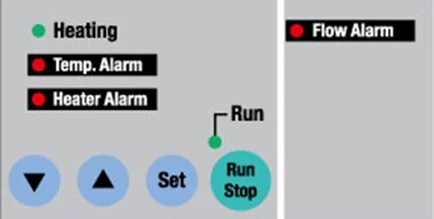

• Easy-to-read, user-friendly operation and control panel

• Safety design

The microcomputer self-diagnosis function detects temperature abnormalities, airflow abnormalities, heater disconnection, and pumping pressure abnormalities. Safety features include earth leakage and overcurrent breakers, overheating protection, and a rubber tray in the tubing section for enhanced safety.

• Rational layout of piping

The piping paths are arranged in an optimal position and shortest distance to minimize liquid pooling and sample sedimentation.

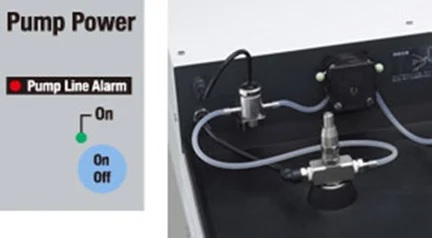

• Pressure abnormality detection function

To prevent issues such as the detachment or damage of the liquid supply tubing from the nozzle due to nozzle clogging, a pressure sensor is installed in the liquid supply path to detect pressure abnormalities, trigger an alarm, and automatically stop the operation.

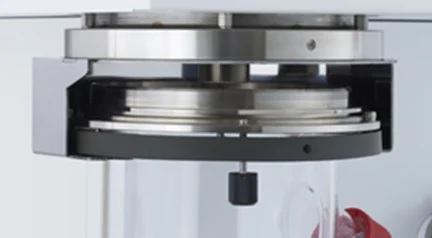

• Nozzle section with excellent maintainability

To facilitate easy cleaning of crystals and other residues attached to the nozzle tip, a cleaning port has been installed on the evaporation tube. The nozzle also features an automatic cleaning mechanism (jet cleaner) with a time setting.

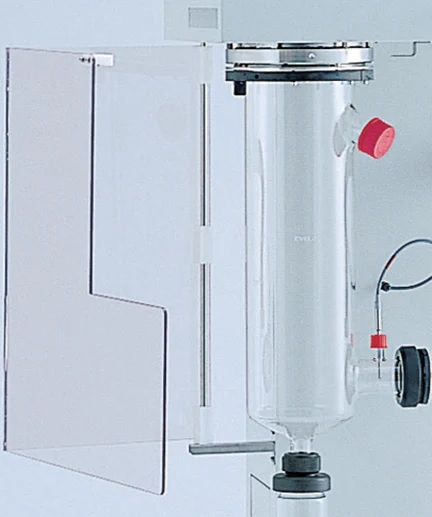

• Prevents evaporation tubes from falling

A new drop prevention stand has been added to prevent the evaporator tube from falling. During installation, the stand allows temporary placement of the evaporation tube, and during removal, it helps prevent the tube from falling.

• Protection cover

The evaporation tube becomes hot in certain areas due to the hot air during operation. A protective cover is installed to prevent accidental contact.

• Easy disassembly, cleaning, and reassembly

The new design allows for smooth disassembly, cleaning, and assembly, which were previously difficult and troublesome. The cyclone has been designed with a structure that makes disassembly and cleaning easier.

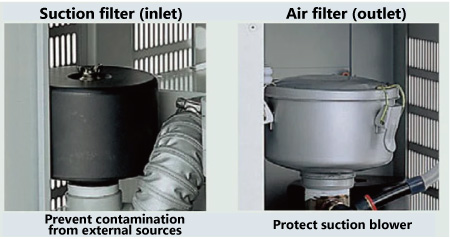

• Standard equipment includes a suction (inlet) filter and an air (outlet) filter

The filter replacement for both the inlet and outlet sides can be easily done through the maintenance doors on the left and right sides of the unit.

• External output

The inlet temperature, outlet temperature, and drying air volume are displayed digitally. Additionally, recorder output functionality is included, allowing for setting, checking, and recording experimental data.

|

Output range | Electrical signal |

| Inlet temperature | 50 to 250℃ | 0 to 10mV |

| Outlet temperature | 50 to 250℃ | 0 to 10mV |

| Drying air volume | 0 to 1m3/min | 0 to 10mV |

♦ The nozzle part of the spray air line has an automatic cleaning function based on a time setting.

♦ A magnetic stirrer, which prevents sample sedimentation and separation, is standard equipment.

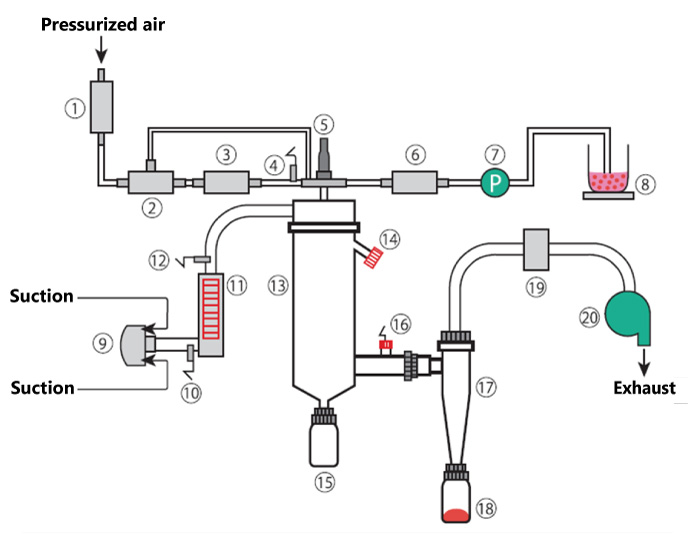

• Flow sheet

| 1 | Spray air line valve (solenoid valve) | 11 | Heater |

| 2 | Three-way solenoid valve | 12 | Sensor (inlet temperature) |

| 3 | Regulator | 13 | Evaporation tube |

| 4 | Pressure sensor (spray air) | 14 | Spray nozzle rinse port |

| 5 | Spray air nozzle | 15 | Separator |

| 6 | Liquid dispensing pressure sensor | 16 | Sensor (outlet temperature) |

| 7 | Liquid dispensing pump | 17 | Cyclone |

| 8 | Sample stirrer (magnetic) | 18 | Powder collector |

| 9 | Suction filter (Inlet) | 19 | Air filter (outlet) |

| 10 | Sensor (wind speed) | 20 | Suction blower |

• Specifications

| Product name | Spray Dryer |

| Model | SD-1010 |

| Cat. No. | 275178 |

| Type | Spray nozzle (Two-fluid nozzle)(Includes 2mm nozzle diameter: suitable for slurry concentration approx. 5 to 30%) |

| Moisture evaporation | Max. 1500mL/h |

| Temperature control accuracy | ±1℃ |

| Temperature control range | 40 to 200℃ (inlet temperature) |

| Spray air pressure control range | 20 to 250kPa (0.2 to 2.5kg/cm2) |

| Heated air volume control range | 0.2 to 0.75m2/min |

| Pump flow rate range | 150 to 1700mL/h |

| Sample stirring rotation speed | 100 to 1000rpm |

| Sample volume | 50mL to 2L (water) |

| Safety features | Evaporation tube protection cover, Earth leakage・ overcurrent breaker, Fixed temperature overheat protector, Manual recovery from power failure, Self-diagnostic function (temperature abnormality, air volume abnormality, heater disconnection, abnormal dispensing pressure) |

| Other functions | Spray air line valve ON/OFF switch |

| External output | 0 to 10m V (inlet/outlet port temp., dry air volume) |

| Heater | 3kW |

| Liquid dispensing pump | Peristaltic pump |

| Spray nozzle | Two-fluid nozzle (nozzle hole 0.71mm ID ) |

| Spray air pump | Air compressor (option) |

| Evaporation tube | Hard glass |

| Cyclone | Hard glass |

| Powder collection vessel | Hard glass (capacity 600mL) |

| Sample stirrer | Brushless DC motor 6W, cobalt magnet |

| Suction blower | Commutator motor, Max. 0.75m3/min variable flow type |

| Tubing | 3.15 ID x 5.2mm OD |

| Spray air connecting port diameter | 4 ID x 6mm OD, soft urethan tube union |

| Spray air pressure | Pressure 294kPa (3kg/cm2), flow rate 25L/min or more |

| Exhaust connecting port diameter | Exhaust port 50mm OD |

| Interval timer | OFF or 1 to 20 min (automatic intermittent operation) |

| Ambient temperature range | 5 to 35℃ |

| Power input | 21A, 4.2kVA |

| Power supply | 220VAC single phase 50/60Hz |

| Power cord | 4.8m・power plug not included |

| Outer dimensions (mm) | 700W x 620D x 1500H |

| Weight | Approx. 110kg |

| Accessories | Silicone tube 3.15 ID x 5.2mm OD x 2m, Exhaust hose 2.5m, Recorder output cable x 3 pcs, Air piping tube 4mm ID x 6mm OD x 5m, Air piping connector (1/4B), Stirring bar |

♦ Performance values are based on room temperature of 20°C, rated power supply voltage of 50Hz, and use of clean water and silicone tubing.

♦ The power plug is not included.

• Data

Operating conditions and recovery rates for various samples

| Sample | Inlet temperature (℃) |

Hot air volume (m³/min) |

Spray pressure (kPa) |

Recovery rate (%) |

| TiO2 | 200 | 0.7 | 180 | 75 |

| Rose extract | 160 | 0.75 | 150 | 71 |

| Ceramics | 160 | 0.65 | 200 | 85 |

| Yeast | 115 | 0.65 | 180 | 64 |

| Plant extract | 180 | 0.65 | 100 | 63 |

| NaCl + Metal salt | 180 | 0.7 | 100 | 69 |

| Sodium polyphosphate | 160 | 0.7 | 100 | 95 |

| Zirconia | 200 | 0.75 | 200 | 62 |

| Monosaccharide & polysaccharide mixture | 160 | 0.7 | 100 | 90 |

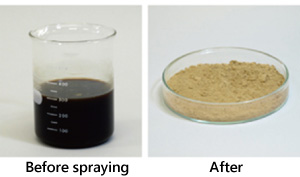

| Coffee | 180 | 0.72 | 180 | 69 |

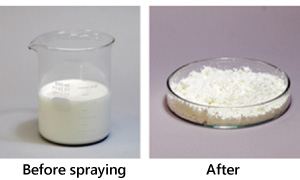

| Milk | 180 | 0.67 | 180 | 57 |

| Titanium | 200 | 0.7 | 200 | 93 |

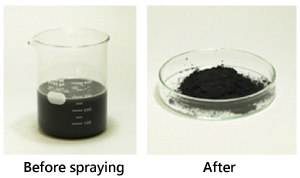

| Carbon | 200 | 0.7 | 200 | 67 |

| Surfactant | 160 | 0.7 | 100 | 66 |

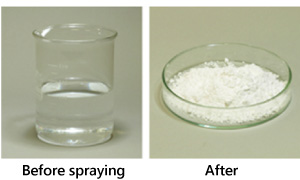

| Saline | 150 | 0.73 | 100 | 91 |

| Agaricus mushroom | 190 | 0.7 | 180 | 61 |

| Sodium terephthalate | 160 | 0.7 | 100 | 66 |

| Tannin | 160 | 0.7 | 100 | 63 |

| Acrylic resin | 160 | 0.7 | 100 | 74 |

| Seawater | 200 | 0.7 | 100 | 65 |

| Alumina | 175 | 0.7 | 150 | 67 |

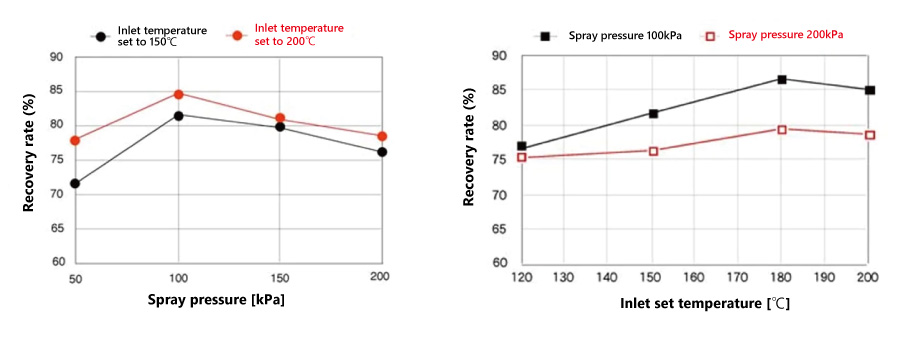

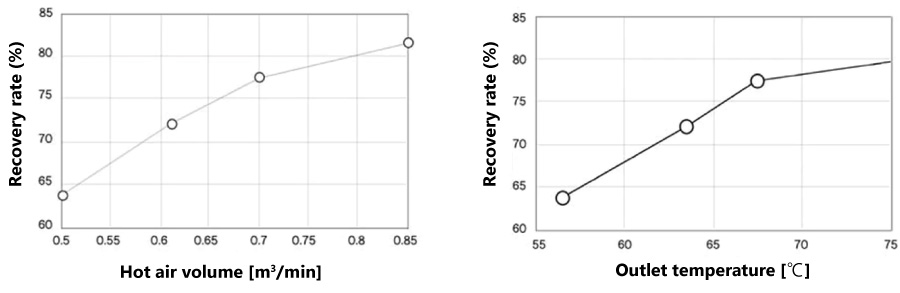

• Operating conditions and recovery rate (10% Sodium metabisulfite solution)

• Operating conditions and recovery rate (Coffee 4%)

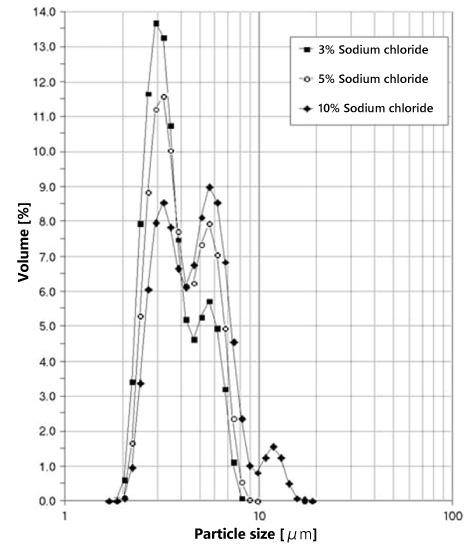

• Particle size distribution

• Testing requests

| Target fields |

Fine ceramics | Pharmaceuticals & Pesticides |

| New metals | Dyes & Pigments | |

| Polymer materials | Organic Compounds | |

| Engineering plastics | Inorganic Compounds | |

| Food & Nutrients | Flavors & Biotechnology | |

| Detergents, Oils & Fertilizers | Pulp & Paper |

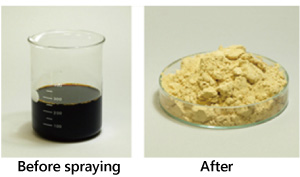

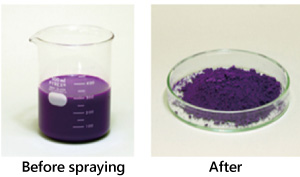

• Examples of spray drying samples

| Ferrite | Salt | ||

|

|

||

| Coffee | Milk | ||

|

|

||

| Soy sauce | Pigments | ||

|

|

◊ Soy sauce contains trace amounts of alcohol, which are removed before spraying.

• Q&A

| Q1 | How much are the dry particles obtained in a spray dryer affected by heat? |

| A1 | Although it may seem that the quality of the particles deteriorates during drying due to exposure to hot air, the actual heat exposure time for the particles is only a few seconds. The latent heat of evaporation suppresses the temperature rise on the particle surface. In practice, the temperature applied to the product remains below 50°C, and the recovered particles cool quickly, resulting in minimal thermal impact. |

| Q2 | How does spray-drying differ from the freeze-drying method? |

| A2 | Freeze-drying is often compared to coffee processing methods. As you may know, freeze-drying involves first freezing the extracted coffee liquid and then sublimating the moisture under reduced pressure to obtain a dried product. The key advantage of this method is that the product is not exposed to heat, resulting in minimal quality degradation and flavor loss. However, drawbacks include the lengthy freezing and drying processes, as well as the tendency for fats and oils to deteriorate in quality. Freeze-drying is the preferred method for coffee to preserve its aroma. On the other hand, spray-drying is used for products such as powdered milk and soups. |

| Q3 | What is the dry particle size? |

| A3 | The particle size obtained with our product ranges from approximately 2 to 40μm.

|

• Options

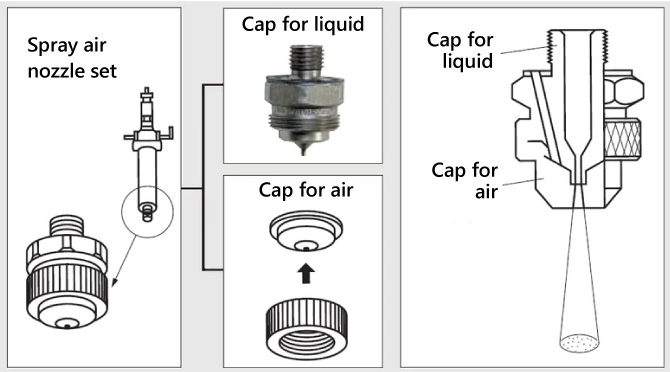

• Caps for the spray air nozzle

The standard accessories include the caps for liquid and air, and needle for a nominal diameter of 2 (slurry concentration of approximately 5 to 30%). Replace the caps and needle of the spray air nozzle according to the slurry concentration of the sample.

| Sample type | Cap hole diameter (mm) | Nominal diameter | Spray air flow rate at P pressure [kPa(kg/cm2)](L/min) |

Model | Cat. No. |

| Homogeneous solution | Cap for liquid 0.41 | 1A | 68.67 (0.7)→1.3 to 147.15 (1.5)→17.0 |

PF-1650-SS | 120710 |

| Cap for air 1.6 | PA-64-SS | 120740 | |||

| Slurry concentration Approx. 5% |

Cap for liquid 0.51 | 1 | 68.67 (0.7)→13.3 to 147.15 (1.5)→20.0 |

PF-2050-SS | 120720 |

| Cap for air 1.6 | PA-64-SS | 120740 | |||

| Slurry concentration Approx. 5% (Powder particle diameter is larger than nominal diameter 1) |

Cap for liquid 0.51 | 2A | 68.67 (0.7)→23.0 to 147.15 (1.5)→36.0 |

PF-2050-SS | 120720 |

| Cap for air 1.75 (standard accessory) | PA-70-SS | 120750 | |||

| Slurry concentration 5 to 30% |

Cap for liquid 0.71 (standard accessory) | 2 | 68.67 (0.7)→19.3 to 147.15 (1.5)→31.0 |

PF-2850-SS | 120730 |

| Cap for air 1.75 (standard accessory) | PA-70-SS | 120750 |

• Other options

| Product | Model | Cat. No. | Reference |

| Needle (selected according to cap hole diameter for liquid) | Y14293-6-1/16-SS | 180250 | For cap hole diameter for liquid 0.41mm |

| Y14293-6-1/20-SS | 180260 | For cap hole diameter for liquid 0.51mm | |

| Y14293-6-1/28-SS | 180270 | For cap hole diameter for liquid 0.71mm (standard accessory) | |

| Hot plate unit

|

HTP-1000 | 275300 | The optional hot plate unit can be used to heat the sample while spraying. This is effective for samples that crystallize when the liquid temperature drops. Max. ultimate temperature: 180°C (plate surface) Stirring plate dimensions: 135mm diameter |

| External temperature sensor | - | 265680 | For hot plate unit |

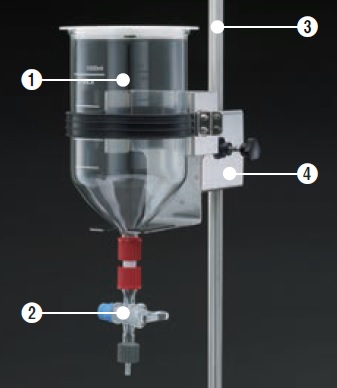

| Vessel with drain port set ①②③④)

|

- | 275640 | An optional vessel set with a drain port is available, allowing slurry or solids-containing liquids to be poured completely. Please use it together with the stirrer. |

| ①Vessel with drain port | - | 275210 | - |

| ②Two-way cock set | - | 275220 | - |

| ③Pole for SD-1010 | - | 275200 | - |

| ④Holder for vessel with drain port | - | 275230 | - |

| Suction filter (inlet)

|

- | 179950 | Standard accessory |

| Air filter (outlet)

|

- | 179960 | Standard accessory |

| Separator / powder collector (600mL)

|

- | 146750 | Standard accessory

Resin-coated EYELACOAT® specifications are also available to reduce glass shattering. |

| Powder collector (1.2L)

|

- | 147940 | Resin-coated EYELACOAT® specifications are also available to reduce glass shattering. |

| Recorder

|

μR-10000 for SD-1010 | 219260 | Number of measurement points 6 points, 6 color ribbons Measurement cycle 6 points/10sec (fastest) Input VDC: 5 types, TC: 1 type, RTD: 2 types |

| Air compressor

Note: This product cannot be exported from Japan. Please source an equivalent model locally.

|

0.2LE-8SBA | - | Discharge air volume (50/60Hz): 20/24L/min Tank capacity: 30L Control pressure (㎏f/㎠): 3.5 to 5.0 Power input: 4.1A |

| 0.4LE-8SB | - | Discharge air volume (50/60Hz): 42/49L/min Tank capacity: 30L Control pressure (㎏f/㎠): 5.0 to 7.5 Power input: 7.7A |

|

| Exhaust hose | - | 179980 | 2.5m (standard accessory) |

| - | 179990 | 5m | |

| Silicone tube | - | 125510 | 3.15 ID x 5.2mm OD, 5m |