• Spray freeze drying (SFD) granulation method

• Enables preparation of porous samples with extremely high solubility

◊ This product was jointly developed with Professor Koichi Okamoto and Researcher Takehiro Noda from the Faculty of Pharmaceutical Sciences, Meijo University, Japan.

• Characteristics of each drying method

| Spray freeze drying granulation method (SFD method) | |

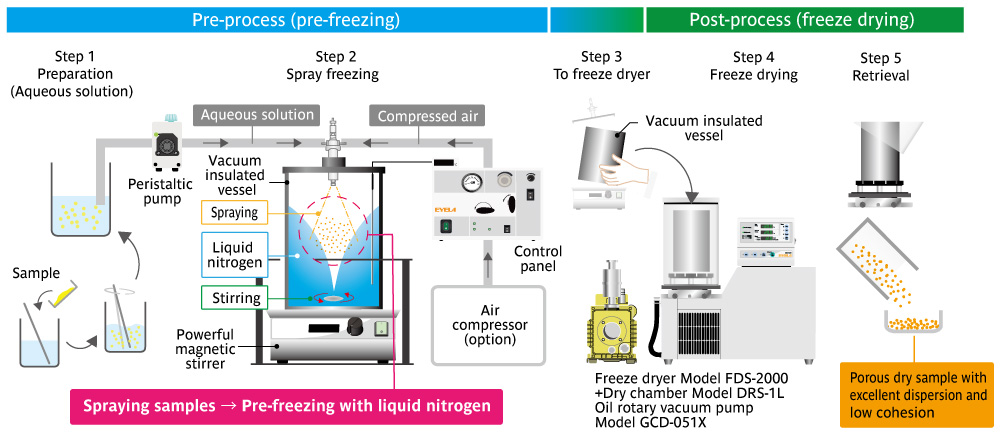

| This is a method of obtaining porous fine particles by spraying a sample (aqueous solution) in liquid nitrogen, freezing it, and then drying it. The freezing process takes place in an instant, and a granulation effect is achieved. Since no heat is applied, no shrinkage occurs in the fine particles. Compared to the spray drying method, this method produces samples that are more porous, soluble, dispersible, and less cohesive. | |

|

|

| Spray drying method | |

| It takes more heat and has a lower yield, but it takes less time and allows for the preparation of fine particle samples. | |

|

|

| Freeze drying method | |

| It is time consuming and does not produce fine particles, but it is possible to prepare samples with good yields without applying heat. | |

|

|

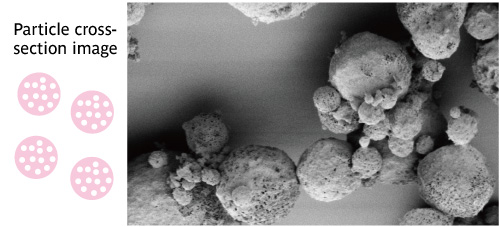

• Features and images of fine particles dried by each drying method

D-Mannitol (a type of sugar alcohol commonly used as a sample in pharmaceutical research)

Note: Electron microscope image, 2000x magnification

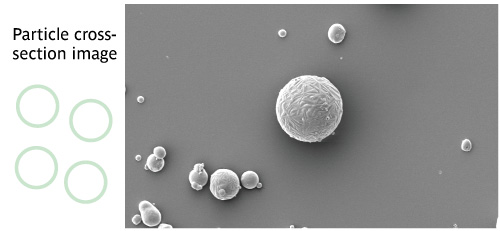

♦ Spray freeze drying granulation method (SFD method)

Since spraying occurs in the pre-process (pre-freezing), granulation effects are achieved, and no shrinkage occurs in the fine particles due to the absence of heat. Additionally, the dried particles are less likely to be cohesive and disperse easily.

♦ Spray drying method

High heat of 100°C or more is applied instantaneously during drying, which causes shrinkage of fine particles and produces hollow particles. As they are not porous, they tend to be cohesive and are difficult to disperse.

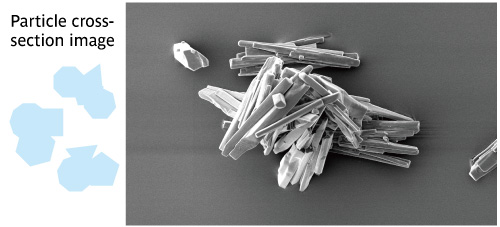

♦ Freeze drying method

Since drying occurs without applying heat, shrinkage does not occur. However, because fine particles are not processed during the pre-freezing stage, granulation effects are not achieved, and the shape of the fine particles becomes irregular.

• Spray Freeze Drying (SFD) granulation process

• Specifications

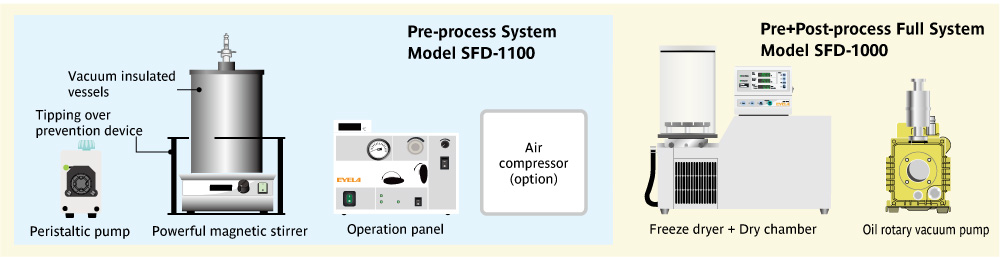

| Product | Spray Freeze Drying (SFD) Granulation Unit | |

| Set name | Pre+Post-process (Full system) | Pre-process System |

| Model | SFD-1000 | SFD-1100 |

| Cat. No. | 279492 | 279501 |

| Processing volume | Max. 150mL/batch | |

| Spraying air pressure adjustment range | 100 to 250kPa | |

| Pump flow rate range | 51 to 900mL/h (Peristaltic pump NRP-1000) | |

| Sample stirring speed range | 50 to 1600rpm (Powerful magnetic stirrer RCX-1100D) | |

| Spray nozzles | Two-fluid nozzle (nozzle hole diameter 0.71mm: nominal diameter 2) | |

| Air compressor | Option: Discharge air volume 10L/min (50Hz), control pressure 300kPa | |

| Freeze dryer trap temperature | -80°C | - |

| Freeze dryer dehumidification volume | 750mL/batch | - |

| Control panel | Spray air valves (x 2), Bourdon tube vacuum gauge, Flow control knob, AC outlet (for spray air pump, peristaltic pump, powerful magnetic stirrer), Power connector for anti-frost heater, Power switch (for pump, heater, and overall), Fuses (x 3) | |

| Vacuum insulated vessel | Standard 3L stainless steel vessel (148 OD x 243H mm) | |

| Vacuum insulated vessel lid | Spray nozzle with vertical stroke length of 39mm, Liquid nitrogen gas exhaust nozzle (20.5mm OD), Heater (100W x 2) for frost prevention | |

| Tubing diameter | 3.15 ID x 5.2mm OD (silicone tubing) | |

| Spray air connection diameter | 4 ID x 6mm OD (union joint for flexible urethane tubing) | |

| Exhaust connection diameter | 20.5mm OD | |

| Ambient operating temperature | 5 to 35°C | |

| Supply voltage | 100VAC 50/60Hz | |

| Power input | 16A | 7.5A |

| Configuration | Spray freeze drying unit (cover + control box), Vacuum-insulated vessel (3L), Powerful magnetic stirrer RCX-1100D, Tip-over prevention device, Air/pump tubing, Pump output cable, Pressure releasing valve for connection to facility, Air compressor (option) | |

| Freeze dryer Model FDS-2000, Drying chamber Model DRS-1L, Oil-sealed rotary vacuum pump GCD-051X, Vacuum hoses | - | |

♦Performance values are based on room temperature (20°C), rated power supply voltage, 50Hz, and no-load conditions.

♦When 1.2L of liquid nitrogen is added to the 3L insulated vessel, it completely evaporates in approximately 10 minutes. The batch processing capacity is defined as the amount of liquid that can be delivered during this 10-minute period when operating the NRP-1000 peristaltic pump at its maximum flow rate.

♦The power input value of the SFD-1000 model includes the power input of the subsequent freeze dryer and the oil rotary vacuum pump.

• Options

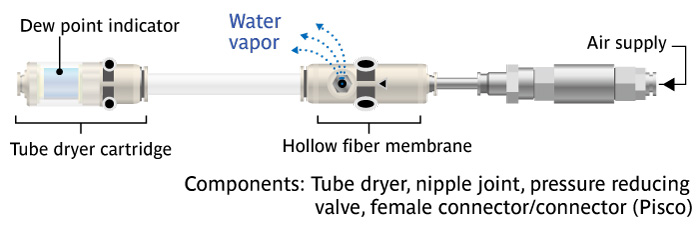

| Product | Tube Dryer Set (Ambient operating humidity Max.70%RH) |

| Set contents |  |

| Cat. No. | 280200 |

| Remarks | •During sample spraying, moisture inside the insulated vessel also freezes. •The tube dryer, using a hollow fiber membrane, can separate water vapor from compressed air. •If you need to transfer the frozen sample from the insulated vessel to a tray or petri dish in the subsequent freeze-drying process, please purchase a tube dryer. •It can be used simply by attaching it to the air inlet of the spray nozzle. •When the color of the dew point indicator turns red, it is time to replace the unit. •The tube dryer cannot be disassembled. |

◊Please purchase the replacement tube dryer cartridges as needed. Cat. No. 280190

| Drying chamber for 3L vacuum insulated vessels |

Air compressor (recommended) | ||

| Product |  |

|

|

| DRS-1L (for FDS-2100・2200) | DRC-1LL (for model FDM・FDL) | 0.2LE-8SBA | |

| Cat. No. | 279310 | 279400 | - |

| Remark | This is a dedicated long-tube drying chamber that can accommodate the standard 3L vacuum-insulated vessel. After sample spraying, the vessel can be directly set inside the drying chamber. | •Discharge air volume: 20/24L/min (50/60Hz) •Tank capacity: 30L •Control pressure: 3.5 to 5.0kgf/cm² •Power input: 4.1A Note: This product cannot be exported from Japan. Please source an equivalent model locally. |

|