• Model VOS-210C and VOS-310C

• Equipped with a timer, basic program functions, and self-diagnostic features

• Ideal for drying, degassing, defoaming, moisture analysis, baking, and more

♦ Simple vacuum drying ovens featuring constant value operation and timer functions (Auto-start, Auto-stop)

♦ Includes a temperature compensation function to match the displayed temperature to the actual temperature measured at the sample position using a standard thermometer

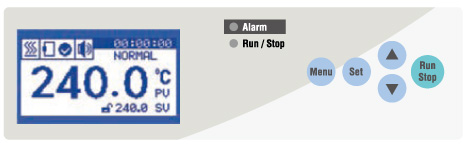

• Operation control panel

The display panel is equipped with a bright, high-visibility LCD.

Icons make it easy to monitor the operating status at a glance.

• Variable independent overheat protector

A variable independent overheat protector is installed separately from the temperature controller for added safety.

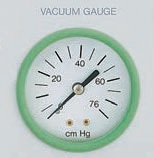

• Vacuum gauge

• Inert gas replacement

Replacing the chamber atmosphere with nitrogen or other inert gases enables drying in an oxygen-free environment.

• Specification

| Product | Vacuum Drying Ovens | |

| Model | VOS-210C | VOS-310C |

| Cat. No. | 263800 | 263810 |

| Heating method | Chamber heating method | |

| Temperature control range | 40 to 240°C | |

| Temperature control accuracy | ±1.5°C (at 240°C) | |

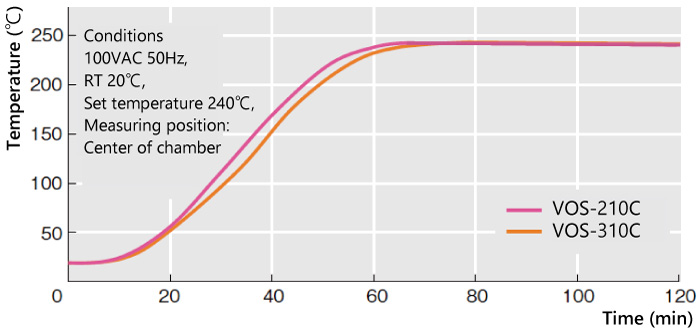

| Heating-up time | Approx. 80 min | |

| Ultimate vacuum | 133Pa (1Torr) | |

| Temperature control | PID control with auto-tuning function, SSR output | |

| Timer function | Auto start, Auto stop | |

| Program function | 1-step, 2-step repetition | |

| Safety features | Self-diagnostic functions (sensor alarm, overheat alarm, power failure alarm, door alarm, setting value error alarm (VOS-451SD/601SD only), upper/lower temperature limit alarm, heater disconnection alarm), Earth leakage/overcurrent breaker, Variable independent overheat protector (50 to 300°C) | |

| Heater | 0.75kW | 1.2kW |

| Vacuum gauge | Bourdon tube type (scale 0 to -0.1MPa) | |

| Temperature sensor | Platinum resistance thermometer (Pt100 ohms) | |

| Inner chamber dimensions (mm) | 192W×270D×192H | 300W×300D×300H |

| Chamber capacity | 10L | 27L |

| Shelf maximum load | Uniform load max.15kg | |

| Shelf material | Stainless steel | |

| Number of shelves included | 2 shelves (max. number of shelves installed: 2) | 2 shelves (max. number of shelves installed: 4) |

| Shelf pitch・number of shelves | 90mm・2 tiers (fixed) | 71mm・4 tiers (fixed) |

| Observation window (mm) | 160W×160H | 250W×250H |

| Inner door | Tempered glass, 12mm thick | |

| Gas-contacting parts material | Door gasket: Silicone, Cabinet interior: Stainless steel, SUS430J1L, Glass, piping: Copper, Brass, Fluoro rubber, Aluminum | |

| Connection diameter | Suction nozzle: 22mm OD hose port, Purge nozzle: 22mm OD hose nozzle (internal thread G1/4) | |

| Ambient temperature range | 5 to 35°C | |

| Power input | 7.7A, 0.77kVA | 12.5A, 1.25kVA |

| Supply voltage | 100VAC 50/60Hz | |

| Outer dimensions (mm) | 355(373)W x 406(431)D x 580H | 505(523)W x 545(570)D x 760H |

| Weight | Approx. 40kg | Approx. 60kg |

♦ Performance values are based on room temperature of 20°C, rated power supply voltage, 50 Hz, and no load.

♦ The heating-up time is measured under reduced pressure and is based on the temperature of the chamber surface.

♦ Dimensions in parentheses ( ) include protrusions.

• Data

• Heating curve

• Options

The stand is robustly constructed to support the oven while optimizing workspace usage.

| Examples of using the stand | |

| vacuum drying oven | VOS-210C |

| Desktop cold trap | UT-1000 |

| Diaphragm vacuum pump | NVP-2000 |

| Stand | HSS-11C |

| Product | Model | Compatible model | Cat. No. |

| Stand | HSS-11C | VOS-210・310 | 100290 |

| Shelf boards | ー | VOS-210C | 100800 |

| ー | VOS-310C | 100810 |

• Related products

| Example of system combination with vacuum pump and cold | |

| Vacuum drying oven | VOS-310C |

| Cold trap | UT-4000A |

| Oil rotary vacuum pump | GCD-136XN |

| Stand | HSS-11C |

| Models | Standard | Power supply | Cat. No. | Compatible vacuum drying ovens | ||||

| VOS-210C | VOS-310C | VOS-452SD | VOS-602SD | |||||

| Oil

rotary vacuum pumps |

GLD-051 | Displacement 50/60L/min (50/60Hz) | 100VAC

220VAC |

190840

190848 |

Yes | Yes | ||

| GLD-137CN | Displacement 135/162L/min (50/60Hz) | 100VAC

220VAC |

270580

270588 |

Yes | Yes | |||

| GLD-202BN | Displacement 200/240L/m (50/60Hz)in | 100VAC | 270600 | Yes | ||||

| GCD-051X | Displacement 50/60L/min (50/60Hz) | 100VAC

220VAC |

190850

190858 |

Yes | Yes | |||

| GCD-136XN | Displacement 135/162L/min (50/60Hz) | 100VAC

220VAC |

189160

189168 |

Yes | Yes | |||

| GCD-136XN (200V) | Displacement 135/162L/min | 200VAC | 189170 | Yes | Yes | |||

| GCD-201XN (200V) | Displacement 200/240L/min | 200VAC | 189180 | Yes | ||||

| GCD-201XN | Displacement 200/240L/min | 100VAC | 189190 | Yes | ||||

| Cold

traps |

UT-3000A | Dehumidifying volume Max. 1kg (water), Ultimate temperature -50℃ | 220VAC

115VAC |

216158

216159 |

Yes | Yes | ||

| UT-3010L | Dehumidifying volume Max. 4kg (water), Ultimate temperature -50℃ | 100VAC | 279990 | Yes | Yes | Yes | ||

| UT-4000A | Dehumidifying volume Max. 1kg (water), Ultimate temperature -80℃ | 220VAC

115VAC |

216178

216179 |

Yes | Yes | |||

| UT-4000L | Dehumidifying volume Max. 4kg (water), Ultimate temperature -80℃ | 220VAC

115VAC |

216188

216189 |

Yes | Yes | Yes | Yes | |

• Transparent cover with nozzle (made of acrylic)

♦ Used in combination with UT-3010 and 4000 series as a vapor trap for aqueous samples.

♦ The inside of the trap chamber is visible at all times without releasing the vacuum.

♦ The nozzle section can rotate 360°, allowing connection without applying bending stress to the vacuum hose.

♦ Equipped with a cover retainer to prevent the cover from falling off the equipment after pressure release.

♦ When used in combination with the optional trap monitor, the system can alert you with an alarm when the trap liquid reaches saturation.

• Cover with nozzle (made of stainless steel)

♦ Used for vapor trapping of aqueous samples in combination with UT-3010 and UT-4000 series.

♦ Used for vapor trapping of aqueous samples in combination with UT-3010 and UT-4000 series.

♦ Equipped with a cover retainer to prevent the cover from falling off the equipment after pressure release.

♦ This cover is not transparent, so the inside of chamber is not visible during operation.

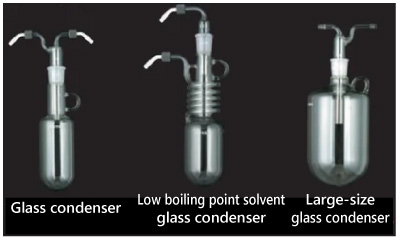

• Glass condensers

♦ Used to trap acid and organic solvent vapors in cold trap.

♦ Made of highly durable glass resistant to low temperatures, capable of withstanding environments as cold as -100°C.

♦ In low boiling point solvent glass condensers, the vapor first passes through the coiled tubing, increasing the contact (heat exchange) area with the low temperature area and improving recovery efficiency.

♦ High boiling point solvents and solvents whose freezing points exceed the trap temperature cannot be used as they may freeze and clog the coiled tubing.

♦ A nozzle cap is installed at the piping connection between the glass condenser and the vacuum hose, making it easy to connect to the vacuum hose. The nozzle cap is made of PP and the O-ring is made of Perfluor. It has excellent corrosion resistance.

♦ Glass condenser set C includes a glass condenser, pole, clamp, muff, and PVC chamber cover.

| Product | Compatible model | Standard | Connection diameter (mm) | Dehumidifying volume (water) | Cat. No. |

Transparent cover with nozzle (Rotating nozzle structure)

|

UT-3010A・4000A | Cover: made of acrylic | 17.3 | 1.0kg | 216210 |

| UT-3010L・4000L | 20 | 4.0kg | 216220 | ||

Cover A with nozzle

|

UT-3010A・4000A | Cover: made of stainless steel | 17.3 | 1.0kg | 148940 |

| UT-3010L・4000L | 20 | 4.0kg | 185890 | ||

| Glass condenser set C | UT-3010A・4000A (Configuration: glass condenser, pole, clamp, muff, PVC chamber cover) |

Standard | 10 | 500mL | 217540 |

| Glass condenser set C for Low boiling point solvents | For low boiling point solvents | 10 | 500mL | 217560 | |

| Large-scale glass condenser set C | UT-3010A・4000A (Configuration: glass condenser, pole, clamp, muff, PVC chamber cover) |

Large scale | 10 | 1800mL | 217580 |

| Glass condenser

|

For glass condenser set C | 80mm diameter x 332H | 10 | 500mL | 217510 |

| Glass condenser for Low boiling point solvents

|

For glass condenser set C for Low boiling point solvents | 80mm diameter x 340H | 10 | 500mL | 217520 |

| Large-scale glass condenser

|

For large-scale glass condenser set C | 150mm diameter x 375H | 10 | 1800mL | 182470 |

• Vacuum hoses and adapters (for connecting hoses of different sizes)

| Product | Standard (mm) | Length / QTY | Cat. No. |

| Vacuum hoses | 18 ID x 42 OD | 5m | 119230 |

| 12 ID x 30 OD | 5m | 119210 | |

| 9 ID x 21 OD | 5m | 119190 | |

| 6 ID x 15 OD | 5m | 119170 | |

| Adapter A | 22 OD x 17 OD | 1 | 119240 |

| Adapter B | 17 OD x 13 OD | 1 | 119250 |

| Adapter C | 17 OD x 10 OD | 1 | 119260 |

| Adapter D | 22 OD x 13 OD | 1 | 119270 |

| Adapter E | 13 OD x 10 OD | 1 | 119280 |

| Adapter F | 22 OD x 10 OD | 1 | 191660 |