• Model VOS-452SD and VOS-602SD

• New design for improved operability and reliability, reducing sample scattering and contamination

• Available in two chamber sizes — 91L and 216L — for a wide range of applications

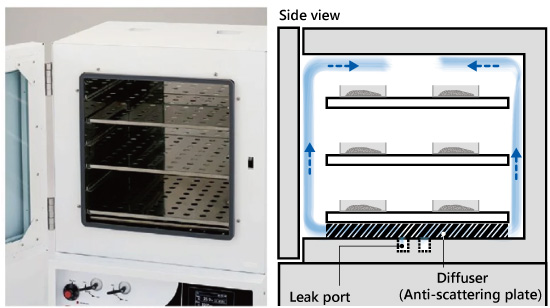

• Prevents contamination by suppressing the scattering of powders and fine particles in the chamber

♦ The anti-scattering plate is installed at the bottom of the chamber. This plate suppresses scattering of powder samples at the time of vacuum release, thereby preventing contamination. The powder sample scattering control capability can be further improved by attaching the slow leak tube.

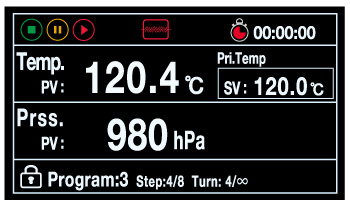

• Bright, easy-to-read 4.3-inch color LCD digitally displays vacuum level

♦ The bright, easy-to-read 4.3-inch color LCD display improves operability and visibility. The screen digitally displays not only the temperature inside the chamber, but also the vacuum level in 1hPa increments.

• Supports validation. Temperature can be measured even under vacuum conditions

♦ Two standard sensor ports are equipped on the top part of equipment, allowing temperature measurement even in a vacuum. (Sensors and recorders are optional.)

Note: Continuous operation for more than 24 hours is not possible when sensors or other devices are inserted.

• Equipped with a slide base stand for oil rotary vacuum pump

♦ Model VOS-602SD is equipped with a dedicated stand. The slide base stand makes oil changes on the rotary vacuum pump easier.

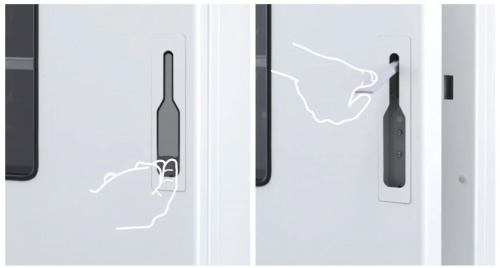

• Our uniquely designed handle with no protrusions

♦ The handle features our unique design, allowing for easy opening and closing while ensuring secure fastening without excessive force and preventing vacuum leaks. Additionally, since the handle does not protrude, there is no risk of clothing or other items getting caught, ensuring safe and comfortable use.

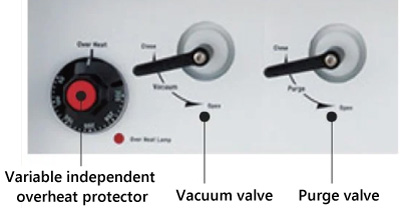

• Easy operation from the front of equipment

♦ The variable independent overheat protector is front-mounted to prevent setting oversights and operational errors. Checking the set temperature is also easy. The valve operation is simple, requiring just a twist to open or close.

♦ The open/close status can be easily checked at a glance. When attaching the included slow leak tube to the leak port, even if the valve is fully opened during vacuum release,air will not enter rapidly. Additionally, by installing the included filter, dust is effectively blocked.

• Specification

| Product | Vacuum Drying Oven | |

| Model | VOS-452SD | VOS-602SD |

| Cat. No. | 279690 | 279700 |

| Heating method | Chamber heating | |

| Temperature control range |

40 to 210°C | 40 to 200°C |

| Temperature control accuracy |

±1.0°C (at 210°C℃) | ±1.0°C (at 200°C) |

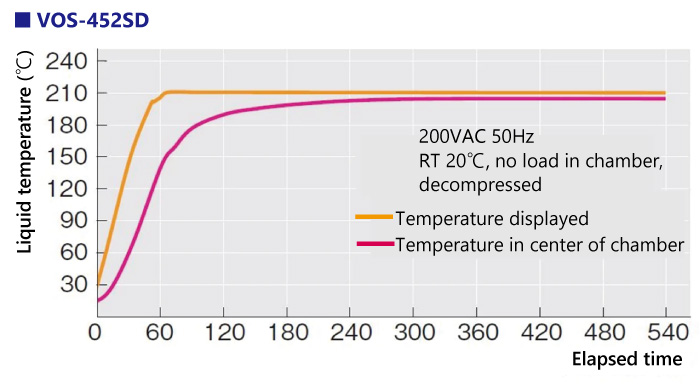

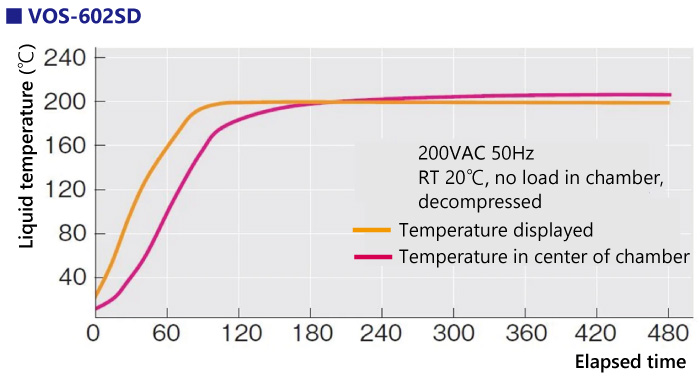

| Time to reach temperature |

Approx. 80 min (40→210°C) | Approx. 110 min (40→200°C) |

| Ultimate vacuum | 1hPa (0.75Torr) | |

| Temperature control | PID control | |

| Timer function | Auto Start, Auto Stop | |

| Program function | Step operation (within 8 steps), 24-hour cycle | |

| Safety features | Self-diagnostic functions (temperature sensor error, power failure recovery, door alarm, upper and lower temperature limit alarm, heater short, heater disconnection), Earth leakage・ overcurrent breaker, Variable independent overheat protector (VOS-452SD: 50 to 270°C, VOS-602SD: 50 to 260°C) |

|

| Heater | 2.1kW | 2.5kW |

| Pressure display | Digital display, 0 to 1066hPa, minimum digit 1hPa | |

| Temperature sensor | Pt100 ohms | |

| Internal dimensions (mm) | 450W x 450D x 450H | 600W x 600D x 600H |

| Internal capacity | 91L | 216L |

| Shelf load capacity | Uniform load 15kg per shelf | |

| Number of shelves included | 3 pieces (mountable 6pcs) | 4 pieces (mountable 6pcs) |

| Shelf Pitch / Number of shelves |

71mm / 6 shelves (fixed) | 95mm / 6 shelves (fixed) |

| Observation window | 250W x 250H (mm) | 430W x 430H (mm) |

| Door inner surface | Tempered glass, thickness 15mm | Tempered glass, thickness 19mm |

| Chamber interior | Stainless steel | |

| Connection diameter | Suction nozzle: 22mm OD hose Purge nozzle: 16mm hose (internal thread Rc1/4) |

|

| Ambient temperature range |

5 to 35°C | |

| External dimensions (mm) | 655(673)W x 597(605)D x 905H | 860(878)W x 780(785)D x 1720 (1780)H(including stand) |

| Weight | Approx. 135kg | Approx. 345kg |

| Power input | 10.75A, 2.15kVA | 12.75A, 2.55kVA |

| Supply voltage | 15A, 200VAC Single phase 50/60Hz | |

♦ Performance values are at room temperature of 20°C, rated power supply voltage, 50Hz, and no load.

♦ The temperature ultimate time is measured under reduced pressure, and the temperature refers to the value on the surface of the chamber.

♦ The recorder output terminal outputs temperature or pressure values. This can be set on the control panel.

♦ The height ( )H of VOS-602SD in the external dimensions includes the stand. The dimensions in ( ) include protrusions.

♦ The upper limit of the temperature adjustment range can be changed to 240°C by using the optional Viton® door gasket. (VOS-452SD only)

Product name: Viton® door gasket Cat. No.: 278860

♦ Power plug not included.

• Options

• Stand, Shelf, recorder output cable

| Product | Model | Cat. No. |

| Stand | ||

| VOS-452SD | HSS-21C | 100300 |

| Shelves | ||

| VOS-452SD | ー | 100820 |

| VOS-602SD | ー | 100830 |

| Recorder output cable | ||

| ー | 147570 | |

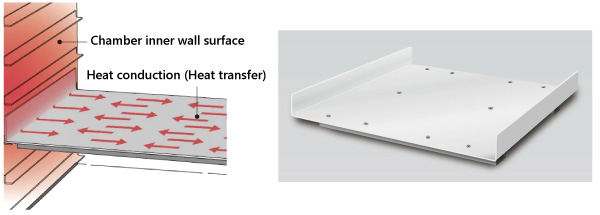

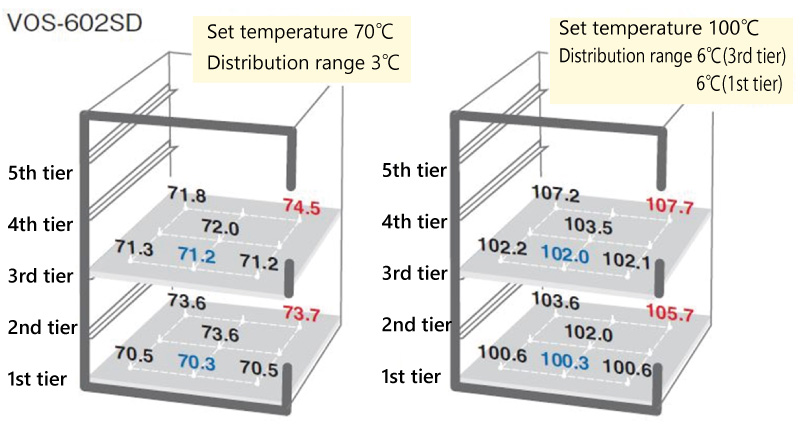

• Uniform temperature distribution shelves (PAT.P)

Our proprietary heating method (PAT.P) maintains uniform shelf surface temperature, allowing for vacuum drying with minimal temperature variation.

| Compatible models | Cat. No. |

| VOS-452SD | 281000 |

| VOS-602SD | 281010 |

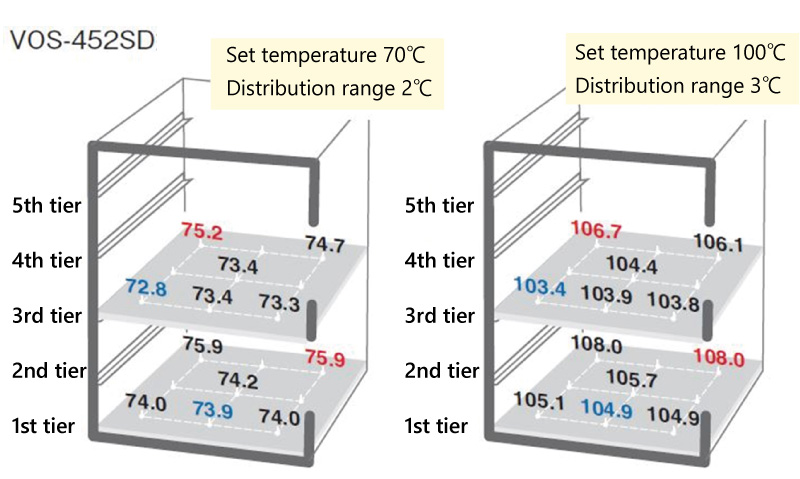

• Surface temperature distribution data

• Related products

• Example of system configuration with related equipment, vacuum pump, and cooling trap

| Vacuum drying oven: | VOS-452SD |

| Cold trap: | UT-3010L |

| Oil rotary vacuum pump: | GCD-136XN |

| Stand: | HSS-21C |

• Compatible models

| Model | Specification | Supply voltage | Cat. No. | Compatible vacuum drying oven | ||||

| VOS-210C | VOS-310C | VOS-452SD | VOS-602SD | |||||

| Oil

rotary vacuum pumps |

GLD-051 | Displacement 50/60L/min (50/60Hz) | 100VAC

220VAC |

190840

190848 |

Yes | Yes | ||

| GLD-137CN | Displacement 135/162L/min (50/60Hz) | 100VAC

220VAC |

270580

270588 |

Yes | Yes | |||

| GLD-202BN | Displacement 200/240L/min (50/60Hz) | 100VAC | 270600 | Yes | ||||

| GCD-051X | Displacement 50/60L/min (50/60Hz) | 100VAC

220VAC |

190850

190858 |

Yes | Yes | |||

| GCD-136XN | Displacement 135/162L/min (50/60Hz) | 100VAC

220VAC |

189160

189168 |

Yes | Yes | |||

| GCD-136XN (200V) | Displacement 135/162L/min (50/60Hz) | 200VAC | 189170 | Yes | Yes | |||

| GCD-201XN (200V) |

Displacement 200/240L/min | 200VAC | 189180 | Yes | ||||

| GCD-201XN | Displacement 200/240L/min (50/60Hz) | 100VAC | 189190 | Yes | ||||

| Cold traps | UT-3000A | Dehumidifying volume Max. 1kg (water), Ultimate temperature -50℃ | 220VAC

115VAC |

216158

115VAC |

Yes | Yes | ||

| UT-3010L | Dehumidifying volume Max. 4kg (water), Ultimate temperature -50℃ | 100VAC | 279990 | Yes | Yes | Yes | ||

| UT-4000A | Dehumidifying volume Max. 1kg (water), Ultimate temperature -80℃ | 220VAC

115VAC |

216178

216179 |

Yes | Yes | |||

| UT-4000L | Dehumidifying volume Max. 4kg (water), Ultimate temperature -80℃ | 220VAC

115VAC |

216188

216189 |

Yes | Yes | Yes | Yes | |

• Other devices required for decompression, trap, samples and piping connections

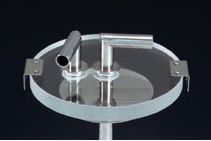

• Transparent cover with nozzle (made of acrylic)

♦ Used in combination with UT-3000 and 4000 series as a vapor trap for aqueous samples.

♦ The inside of the trap chamber is visible at all times without releasing the vacuum.

♦ The nozzle section can rotate 360°, allowing connection without applying bending stress to the vacuum hose.

♦ Equipped with a cover retainer to prevent the cover from falling off the equipment after pressure release.

• Cover with nozzle (made of stainless steel)

♦ Used for vapor trapping of aqueous samples in combination with UT-3000 and UT-4000 series.

♦ Used for vapor trapping of aqueous samples in combination with UT-3000 and UT-4000 series.

♦ Equipped with a cover retainer to prevent the cover from falling off the equipment after pressure release.

♦ This cover is not transparent, so the inside of chamber is not visible during operation.

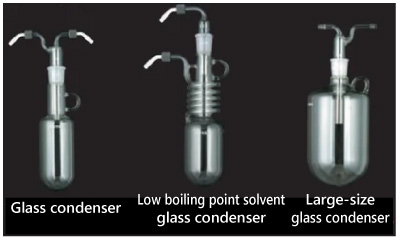

• Glass condensers

♦ Used to trap acid and organic solvent vapors in cold trap.

♦ Used to trap acid and organic solvent vapors in cold trap.

♦ Made of highly durable glass resistant to low temperatures, capable of withstanding environments as cold as -100°C.

♦ In low boiling point solvent glass condensers, the vapor first passes through the coiled tube, increasing the contact (heat exchange) area with the low temperature area and improving recovery efficiency.

| Product | Compatible models | Standard | Connection diameter (mm) | Dehumidifying volume | Cat. No. |

Transparent cover with nozzle (rotating nozzle structure) |

UT-3000A・4000A | Made of acrylic | 17.3 | 1.0kg | 216210 |

| UT-3010L・4000L | 20 | 4.0kg | 216220 | ||

Cover A with nozzle  |

UT-3000A・4000A | Made of stainless steel | 17.3 | 1.0kg | 148940 |

| UT-3010L・4000L | 20 | 4.0kg | 185890 | ||

| Glass condenser set C | UT-3000A・4000A (Configuration: glass condenser, pole, clamp, muff, PVC chamber cover) |

Standard | 10 | 500mL | 217540 |

| Glass condenser set C for Low boiling point solvent | For low boiling point solvents | 10 | 500mL | 217560 | |

| Large-size glass condenser set C | UT-3010L・4000L (Configuration: glass condenser, pole, clamp, muff, PVC chamber cover) |

For large scale | 10 | 1800mL | 217580 |

| Glass condenser

|

For glass condenser set C | 80mm diameter x 332H | 10 | 500mL | 217510 |

| Glass condenser for Low boiling point solvent

|

For Glass condenser set C for Low boiling point solvent | 80mm diameter x 340H | 10 | 500mL | 217520 |

| Large-size glass condenser

|

For Large-size glass condenser set C | 150mm diameter x 375H | 10 | 1800mL | 182470 |

• Vacuum hoses and adapters (for connecting hoses of varying diameters)

| Product | Standard (mm) | Length / QTY | Cat. No. |

| Vacuum hoses

|

18 ID x 42 OD | 5m | 119230 |

| 12 ID x 30 OD | 5m | 119210 | |

| 9 ID x 21 OD | 5m | 119190 | |

| 6 ID x 15 OD | 5m | 119170 | |

| Adapter A

|

22 OD x 17 OD | 1 | 119240 |

| Adapter B | 17 OD x 13 OD | 1 | 119250 |

| Adapter C | 17 OD x 10 OD | 1 | 119260 |

| Adapter D | 22 OD x 13 OD | 1 | 119270 |

| Adapter E | 13 OD x 10 OD | 1 | 119280 |

| Adapter F | 22 OD x 10 OD | 1 | 191660 |

• Data

• Heating characteristics